Everyone has heard of glued beams; beautiful wooden houses are erected from this modern material. But few people wonder what glue for glued beams is used, and how safe is its composition for humans? Unfortunately, often residents expect to get an environmentally friendly home, but in fact, health can suffer due to the use of low-quality adhesive compounds.

- Features of the production of glued beams

- Types of adhesive systems for the manufacture of timber

- Comparison table of properties and prices of adhesives

- The danger of formaldehyde glue

- Popular manufacturers of quality glues for timber

Features of the production of glued beams

Most often, this type of timber is made from coniferous wood, mainly from pine. First, the raw materials (round log) are processed, the bark is removed, the croaker is cut, and then sawed. Usually, three boards (lamellas) are obtained, sawn radially. Obtaining large boards is carried out according to a special technique, taking into account the angle of inclination of the annual rings, which relieves excessive stress and allows the wood to dry faster. Further, for the final drying, the lamellas are subjected to such actions:

- high temperature treatment;

- pressure exposure;

- centrifugation.

Then the lamellas are again processed on machines to achieve smoothness, perfect shape, then glued under a press at a temperature of +200 degrees. For bonding, special compounds are used, which under pressure penetrate into the deepest pores of the wood, giving it a high margin of safety. After final hardening of the glue, the material is planed, cut, creating elements of the desired size.

Glued beams can serve for decades without damage, delamination, but its quality is different. When ordering a building from such a material, it is worth paying attention to the form, form. Some companies make a beam consisting of pieces of 20-40 cm in size, which reduces aesthetics. It is better when during manufacture one splicing of lamellas was made for every 10-15 meters.

to contents ↑Types of adhesive systems for the manufacture of timber

Not all adhesives are suitable for the production of timber. Some of them contain many harmful substances, toxins. Therefore, it is possible to consider laminated veneer lumber as an environmentally friendly material only if the method of its creation is in strict accordance with GOST, SanPiNam and when using suitable adhesives. In general, after hardening, most adhesives do not emit volatile substances, but some have a long final polymerization in the deep layers of wood. Such products are not suitable for gluing timber, and the most dangerous component in them is formaldehyde.

There are several safety classes for the release of phenol formaldehyde with adhesive compounds - E1, E2, E3. Each glue must be tested by the manufacturer, after which the appropriate class is put on its packaging (the safest is E1).

Now there are several types of adhesives that are used for the production of building materials:

- Polymer-isoacetate blends, or EPI. Formaldehyde and other harmful substances (e.g. urea) are not included at all. They allow you to work with timber at temperatures from +5 degrees, do not respond to high humidity, but are expensive.

- Polyurethane adhesives. They harden quickly during hot bonding, have excellent technical characteristics, and are often sold in a single-component form. After complete curing, no hazardous substances are released, although this is possible during operation. Polyurethane adhesives are also expensive.

- Melamine adhesives. They are based on formaldehyde, but have the highest degree of adhesion. They can boast of frost resistance, moisture resistance, after drying they become transparent. Such products are widely used in European countries, because after polymerization they no longer emit harmful fumes, and besides, they are very economical.

- Resorcinol adhesives. As they harden, they become dark. They are difficult to work, since gluing the beam with them is permissible only in the open air. In Russia, Europe, such funds are rarely used, they are more popular in America.

Other compositions for the production of glued beams are not used, because they are not able to provide reliable adhesion of wood. Therefore, PVA, carpentry adhesives for this purpose are not suitable. Often the type of glue does not play a decisive role: harm to the body is caused by a violation of the technology for the production of timber. For example, when the temperature is insufficient or the gluing time is reduced, the complete polymerization of the glue does not occur, and it will release toxins over time.

to contents ↑Comparison table of properties and prices of adhesives

Different means for the manufacture of timber may have different parameters and characteristics. The following are the main features of the three most popular formulations.

| Glue name | External signs | Hardener | Consumption, kg / sq. m | Average cost, rub. |

|---|---|---|---|---|

| Polyurethane | Liquid, light brown | Not | 0,15-0,25 | 480 |

| Melamine | Liquid, milky white | there is | 0,3-0,45 | 470 |

| EPI | Liquid transparent | there is | 0,25-0,4 | 190 |

As can be seen from the table, only polyurethane compounds are sold as single-component adhesives. The remaining funds are sold in two-pack form and require mixing with the hardener before use.

to contents ↑

The danger of formaldehyde glue

Formaldehyde (phenol formaldehyde) is a pungent gas. It is considered a poisonous, toxic substance, in medicine it refers to carcinogens and strong allergens. Some scientists also argue that the substance has mutagenic properties and can adversely affect both the person himself and his future offspring. The connection of formaldehyde with the development of tumors of the lungs and other organs of the respiratory system, as well as bronchial asthma, is proved.

Since regular poisoning of the substance into the body is necessary for poisoning and the development of serious consequences for humans, it is important to exclude living in a house made of low-quality glued timber. Active emission of formaldehyde is present in cheap materials, the price of which is due to the minimum cost of low-grade glue. The conclusion is simple: when buying a timber, you should not save money and you always need to carefully study the certificates for the purchased products.

to contents ↑Popular manufacturers of quality glues for timber

There are adhesive compositions on the market that meet the safety requirements, therefore the beam made on their basis can be used for housing construction. Here are the most popular ones:

- Akzo Nobel. A two-component product without toluene, formaldehyde, is available in the Netherlands. It can even be used for gluing dishes in contact with food. Suitable for the production of glued beams.

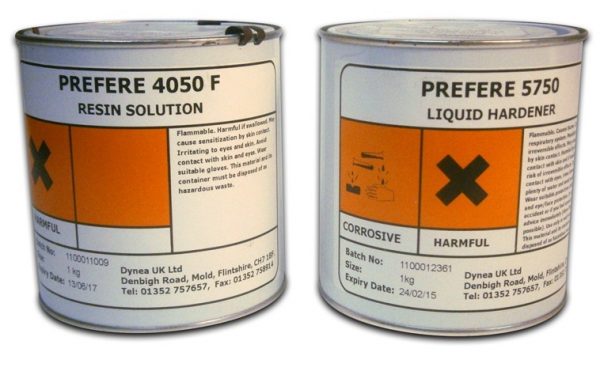

- Dynea-Prefere. This EPI glue can be used to create load-bearing beams made of wood, because it has high adhesion and adhesive joint strength.Environmentally friendly product, does not contain formaldehyde.

- EPI-glue "Himtech". Russian development, does not include toxic components, is considered harmless to humans. Plus - a lower price compared to foreign counterparts.

With the right choice of glue, wood can remain a “breathing” material, will not emit toxins, and the house will become a place of safe living for people. If doubts still remain, it is better to purchase a more reliable material for construction - a solid profile beam, which is 100% natural and does not raise doubts about the quality.