Foam concrete blocks are a modern high-quality material for masonry walls, with which it is quite possible to work with your own hands. But the blocks will serve for a long time and without complaints only if they are laid on a special adhesive composition, and not on ordinary cement mortar. Glue for foam blocks does not have the ability to "pull" moisture from the main material, due to which the seams do not crack and do not collapse.

- Glue application area

- Glue varieties

- Advantages and disadvantages of glue

- Differences between glue and cement mortar - the better

- Glue consumption per cubic and square meter of masonry

- Binder Consumption

- Glue rate per cubic meter of masonry

- Glue consumption per 1 m2 of wall

- The choice of adhesive for foam concrete

- Glue preparation

- Application Method

- Differences between masonry on glue and cement

- Quality requirements for foam blocks

- Adhesive layer thickness

- Possible mistakes

- Which adhesive for foam blocks is better - brands

- Volma

- Titanium

- Knauf

- IVSIL Block / IVSIL Block

- Founces Selfform T112

Glue application area

Glue mixes are widely used in construction, repair, reconstruction - wherever work with foam blocks is carried out. It is recommended to put the foam block on the glue during the formation of different types of buildings - houses, country houses, cottages, baths, utility buildings, garages. Along with aerated concrete, blocks are also popular in the construction of partitions and load-bearing walls, can participate in soundproofing, and are suitable for warming rooms. Also, foam blocks can be used to increase the number of floors in the building.

to contents ↑Glue varieties

In composition, the basis of all funds is approximately the same. Glue for foam concrete blocks necessarily contains Portland cement, which provides quick and reliable setting. Also in the composition, as in tile adhesives, there is fine quartz sand, which allows seams of small thickness to be made. Glues differ in such components:

- modifiers (needed to prevent the appearance of cracks, increase the elasticity of the composition);

- polymeric substances (required for higher ductility, so that the adhesive mixture fills even the smallest irregularities of the masonry).

Also, adhesives for foam blocks are not the same depending on the time of installation and can be winter or summer. Their differences:

- Glues for summer work at + 5 ... + 30 degrees, contain white cement. After mixing, the solution retains its properties for a short time - up to 120 minutes.

- Means for the winter. The range of operating temperatures is -10 ... + 5 degrees. Such mixtures are frost-resistant because they contain special “winter” additives. Dry powder should be diluted with warm water (about +60 degrees), used quickly - in 40 minutes.

Advantages and disadvantages of glue

The composition of the mounting adhesive for foam concrete is designed specifically for this material, because it has a lot of advantages:

- consumption per 1 m2 of surface due to the fine fraction of glue is seriously reduced, because it is not necessary to carry out too thick a layer;

- the masonry lays evenly, which is aesthetically attractive and significantly increases the adhesion of the composition (provided that the work is correctly performed);

- a small amount of water, which is required for breeding the mass, allows you to maintain an optimal microclimate in the house;

- glue reduces the thermal conductivity of the wall, because the risk of the appearance of "cold zones" is minimized;

- the quality and strength of the masonry are very high, while in the future there is no danger of wall shrinkage;

- the material has excellent frost resistance (we are talking about the winter version), does not respond to adverse weather conditions and the effects of atmospheric factors;

- the adhesive layer increases the soundproofing ability of foam concrete, it is hygroscopic, vapor permeable, plastic, does not deform with time, does not crumble;

- the use of glue is available even to beginners, no special knowledge is required for this;

- for mixing the composition, you do not need to buy a concrete mixer, a construction mixer is enough, and small portions of glue can be prepared manually;

- bags of glue of 25 kg are convenient to transport, they are optimal in volume for a single batch of material;

- All components of the adhesive are safe for humans and the environment.

The composition of many glues for foam concrete includes antifungal additives, therefore, even in conditions of high humidity, the material is not subject to the growth of fungus, mold.

The composition also has disadvantages. So, users note higher financial costs for the purchase of glue, when compared with conventional cement and sand. Although when calculating the consumption per 1 m3 of masonry, the calculator will reflect other figures, and, ultimately, you can save a lot. True, to obtain a flow rate of 4-6 times lower than that of a cement mortar, the quality of foam blocks should be at their best. Alignment of tiles with differences, filling voids and chips will lead to a significant change in the calculations.

to contents ↑Differences between glue and cement mortar - the better

The technology for the proper installation of foam concrete differs from the methods of installation of other wall materials, and cement mortar is not suitable for its implementation. The thermal insulation properties of foam concrete blocks are higher than that of mortar, and thick layers of the latter make the structure blown and cold. When using this installation method, it will be necessary to equip additional thermal insulation from inside or outside the wall.

The use of a special adhesive composition solves the problem. It forms a thin seam - durable, waterproof and waterproof, so the room will be noticeably warmer. In addition, laying blocks on glue is easier, faster, it hardens more quickly, reducing construction time. The cement mortar contains a lot of water, which immediately begins to be absorbed into the porous structure of the blocks, so you also have to spend money on a water-repellent primer.

There are cases when you can still lay the blocks on a regular solution:

- material size - about 30 cm;

- incorrect geometry of products;

- deviations in height - more than 1.5 cm;

- the presence of chips.

In other cases, it is better to purchase an adhesive composition, especially when the size of foam blocks is up to 100 mm.

to contents ↑Glue consumption per cubic and square meter of masonry

How to calculate how much glue is needed to work? There are two types of calculations - per one m2 and per cubic meter of the treated surface.

Binder Consumption

Professionals advise more reliable to connect foam blocks to a layer of 3-8 mm thick. In this case, the consumption of binders may be uneven. It greatly depends on the skill of the master, the quality of the glue itself, which is better not to save on. Weak penetration of materials that are too cheap will seriously increase consumption rates. Also, for the construction of houses for permanent residence in cold areas, it is often recommended to carry out the second row of blocks to improve thermal insulation, and the glue consumption will increase. Also, the material costs depend on the type of tool used (a notched trowel reduces the number), weather conditions (in the cold, the risk of spoiling the glue is higher).

to contents ↑Glue rate per cubic meter of masonry

What is the total volume of masonry for a particular building, can be clarified from the design documentation or calculated independently if the project was not drawn up. The total volume in cubes should be calculated by multiplying the perimeter of the wall by the estimated thickness, subtract the volume from the figure:

- windows;

- doors;

- interior jumpers;

- floor floors.

Thus, you only need to identify the volume of the wall itself, although it is rather difficult to do. According to the experience of professionals, the average consumption of glue per 1m3 will be from 15 to 23 kg.

to contents ↑Glue consumption per 1 m2 of wall

The calculation of the area is carried out in a similar way, but without taking into account the thickness of the wall, which reduces the accuracy of the numbers. With an adhesive seam of 1 mm, the consumption per square meter is 1.4-1.7 kg of glue. The indicator must be multiplied by the estimated thickness of the seam to get an approximate amount of material.

The choice of adhesive for foam concrete

The best way to buy a good adhesive is to do practical tests. It is necessary to purchase several brands and glue the finished composition on a pair of blocks. After a day, it is necessary to break the connection and inspect the fault site. If the parts are broken at the seam, you should not use such glue in the future. A joint can also be considered bad, where a partial fracture of the seam with the deformation of the foam concrete itself has occurred. Only the block should suffer, and the glue line should remain intact, in which case the composition is trustworthy.

Another test is performed as follows: 1 kg of each dry mixture is diluted, the same jars are filled. After a day, the containers are weighed. Where the weight is the smallest, the highest quality glue is found. Moisture quickly leaves it, therefore, thermal conductivity will be at an altitude. When it is not possible to test adhesives, the choice should pay attention to the reputation of the manufacturer, frost resistance (if this is important), size of the fraction (it should be small).

to contents ↑Glue preparation

The volume of water specified in the instructions must be poured into the prepared container in proportion to the amount of dry mix. As a rule, 25 kg of powder is used for 7 liters of water. Mix the mass with a construction mixer or drill with a nozzle, applying low revolutions. After thorough mixing, leave the mass to infuse for 5 minutes.

The glue should not be too liquid, it must be well kept on the trowel for application. In addition, excess water will reduce adhesion, so immediately do not dilute the mass strongly. Within 40-120 minutes, depending on the type of glue, you need to fully use the finished portion, then it will thicken. Correction of masonry is permissible within 15 minutes, but solidification will occur in about 4 hours. Final drying lasts about a day.

to contents ↑Application Method

To work, you need a trowel in one block with teeth. Many manufacturers of adhesives for foam concrete blocks give precise recommendations on its width and type. Too wide a tool to take glue is inconvenient, in addition, it can break due to heavy weight. You can also independently make such a device from a sheet of metal. In the absence of a trowel, it is permissible to apply the composition with a trowel and level with a notched trowel.

Work should be done at the temperature indicated on the packaging of the adhesive. At subzero temperatures, only a “winter” version of the material is suitable. It must be bred in the room with hot water. In frost, drying time is faster, and you will have to work even faster.

The foundation, the first layer of foam blocks after it, is usually placed on a cement mortar for the stability of the frame. Next, use an adhesive composition. Before starting to lay the walls, the foundation is covered with a waterproofing material (membrane, roofing material). Start with corner bookmarks. In the presence of elevation differences, the highest angle is first performed, then the others are made according to its level (leveled with a solution). Be sure to reinforce the masonry to reinforce the most stressful areas. To do this, reinforcement is placed around the perimeter (on the upper and lower rows, for every third row, in the area of the openings).

The procedure will be as follows:

- apply glue to a number of foam blocks with a spatula, capturing the horizontal and vertical surfaces;

- to smooth the layer well, applying the building level (according to its indications, the cord must be pulled);

- put a layer of blocks, adjust their location with a rubber mallet;

- continue work to the desired height, maximally pressing individual elements to each other;

- in dry, hot weather, it is recommended to slightly spray the blocks with water from the spray gun;

- leave the masonry to dry for at least a day.

to contents ↑If a special foam-glue is used in cylinders, it is squeezed out one strip on each edge of the foam block. The material itself will spread over the surface, although some practice leveling it with a spatula. Consumption in this case will increase.

Differences between masonry on glue and cement

The main difference between laying blocks on glue is the creation of a rather thin cushioning layer. Professionals manage to perform it within 1-3 mm, although the thickness of the glue line up to 6-8 mm is also allowed. The thinner the layer, the less likely the appearance of “cold bridges” and the lower the need for insulation. Also, laying foam concrete on glue has other differences with installation on a cement mortar:

- exceptional evenness of rows;

- the opportunity to do the work yourself;

- increase the bearing capacity of the wall;

- lower time and energy costs for mixing the material.

Quality requirements for foam blocks

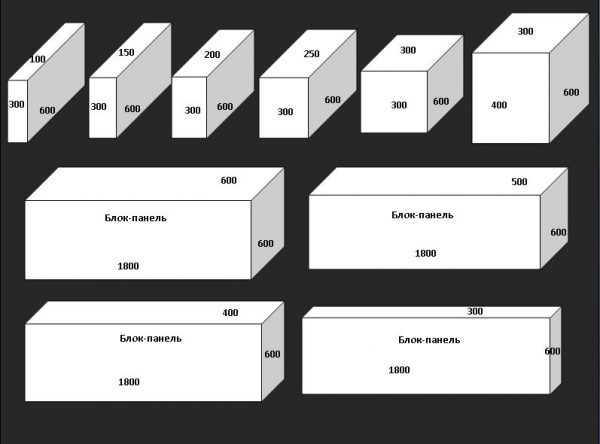

Manufacturers produce blocks of different sizes, they are designed for different purposes. Here are the most popular (cm):

- 20 * 30 * 60 - for bearing internal walls;

- 20 * 40 * 60 - for supporting external walls;

- 10 * 30 * 60 - for partitions.

Blocks of good quality must have equal sizes, then they will fit snugly together. Density is another characteristic of the material, it is indicated by the letter D. For wall insulation, blocks D400-500 are used, for creating load-bearing walls in small houses - D600-900, for large walls and ceilings - D1000-1200. Other material requirements:

- frost resistance (F) - 15-75, selected depending on the climate;

- no cracks;

- color - from light gray to dark, but not whitish;

- lack of black marks of greasing;

- film packaging.

Adhesive layer thickness

If the foam blocks are made with high accuracy, it is quite possible to form thin seams of glue - 1-2 mm. When the surface drops are 2-3 mm, the thickness of the adhesive layer will be up to 4 mm. If the foam blocks are more uneven, you should think about the advisability of using glue. It might be better to fix the material on a cement mortar. There is another option: to purchase a special grater, which can grind the protrusions on the foam blocks, but the work will be time-consuming and long.

to contents ↑Possible mistakes

Often, beginners make a series of oversights in their work, which lead to unpleasant consequences:

- Leaving voids between the blocks due to the lack of glue in vertical sections. Some do not apply glue to the vertical joints of the blocks to save money, but in winter this will lead to moisture accumulation in the cracks. Over time, the seam and the foam block itself will crumble.

- Low offset blocks in subsequent rows. It is necessary to shift the part by ¼ from the size of the previous one, even better - by ½, otherwise the weight will not be distributed correctly.

- Editing foam concrete after setting the glue. If you start moving the product after 15 minutes and later from the moment of applying the adhesive, this will lead to a strong decrease in adhesion to the surface.

- Ignoring masonry reinforcement. Structural strength will be insufficient.

- Early start of wall decoration. You can not plaster the wall earlier than after 3-6 months, otherwise cracks will appear on the finishing layer. First you need to start decorating the blocks from the inside, then from the outside.

Which adhesive for foam blocks is better - brands

Popular firms producing adhesives for foam concrete are Bolars, Knauf, Volma, Poretep. Buying the cheapest glue is not worth it, it is better not to save on quality.

Volma

Glue Volma consists of sand, cement, high-quality dispersion additives. It is suitable for joints with a thickness of 2-5 mm, suitable for aerated concrete, leveling surfaces.

Titanium

It is realized in the form of foam-glue for foam blocks, perfectly replaces cement mortars, is applied in thin strips. The design becomes very durable, and work is carried out most quickly.

Knauf

Knauf Perlfix glue has a gypsum base and polymer additives. It helps align the walls and lay foam blocks. The product is available in bags of 30 kg.

to contents ↑IVSIL Block / IVSIL Block

The material is intended for laying grooved, baseless slabs, suitable for foam, aerated concrete.The thickness of the adhesive layer is from 2 mm, you can adjust the position of the parts within 15 minutes.

Founces Selfform T112

This composition is frost-resistant, withstands up to 75 freezing cycles. The filler fraction is very small, because the seams can be the thinnest - from 1 mm.

Any glue must be properly diluted and applied, in this case, the masonry is performed with maximum accuracy. It will last a long time and does not require repair costs, additional thermal insulation.