Expanded polystyrene extruded (extruded), or EPSS - a popular material for insulation of floors, walls, foundations, roofs. In the process of application, it does not give harmful fumes, but it protects against noise, dust, cold. The material is used for indoor and outdoor use, it can be glued to the surface using special tools. It is not easy to choose adhesive for polystyrene foam, because the choice is very large.

- Features of the installation of expanded polystyrene

- The choice of glue for extruded polystyrene foam

- Glue and plaster mixes

- Ceresit CT-83

- Bergauf ISOFIX

- Polyurethane products

- Tytan Styro 753 GUN

- TechnoNIKOL glue-foam

- Glue "Penopleks" Fastfix

- Bitumast glue

- Polyvinyl acetate adhesives

- "Moment Joiner"

- PVA-MB

- Other gluing methods

- Polyurethane foam

- Hot-melt adhesive

Features of the installation of expanded polystyrene

The extruded PPP is a high density foam. It is this indicator that it differs from ordinary polystyrene - polystyrene. The density increases during the production process when passing through the extruder, this seriously increases the thermal insulation characteristics of the material. The resulting slabs are made up of polymer and small air bubbles.

Due to the smoothness of the board, EPSs have very poor adhesion to the adhesive. This is the main problem when gluing. It is solved by the selection of special adhesives, which in themselves have high adhesion to any surface. Also, some tools can partially dissolve the foam top of the plates, soaking in them.

The specifics of the installation of expanded polystyrene plates are as follows:

- if the material is purchased as insulation for the floor, it is placed on a expanded clay pillow or on a strip of other low-density material and poured with concrete;

- to insulate the foundation, the slab must be glued to the basement concrete and fixed with mounting hardware;

- material is laid on the roof, then a bitumen layer is placed or PPS is laid between the edges of the rafters inside the roof layers;

- when insulating the ceiling in the apartment on the top floor, polystyrene foam is laid from the attic side to the glue, then concrete or covered with crumbs, gravel, expanded clay.

The choice of glue for extruded polystyrene foam

How to glue polystyrene foam? For fixing the plates, you can use different means having different components. But there is a specific application of mixtures. So, for gluing to a concrete base it is better to use some, for fastening to a brick wall - others, for winter work - others. There are adhesives that combine the properties of fixing material and insulation, have low thermal conductivity.

Before buying, it is important to clarify that there are no substances in the composition of the product that corrode polystyrene foam. It:

- acetone;

- alcohol substitutes;

- toluene;

- ethers;

- other solvents.

The ideal option is to acquire specialized formulations, because their manufacturers have already taken into account all the important points. There are three main types of tools that are suitable for bonding material. This is a plaster-glue mixture of different grades, polymer adhesives and bitumen glue (mastic).

People often use “liquid nails” in a bottle, silicone sealants, frost-resistant tile adhesives, drywall agents, and tile for gluing material.Can I use them? Experts say that the use of such adhesives is possible, especially if additional fixing of the structure with dowels is planned. But the cost of work can be much higher, so it is better to buy funds intended for EPSS.

to contents ↑Glue and plaster mixes

Such mixtures are suitable for gluing PPP to plasterboard, brick, concrete, cinder blocks. They need to be bred by ourselves, because they are realized in the form of a dry mass. The composition includes mineral components, plasticizers, Portland cement, a number of auxiliary additives. Mixes are suitable for external works and furnish indoors, they will hide all roughnesses of the basis. The disadvantage is the need for preliminary deep priming of the surface.

to contents ↑Ceresit CT-83

Ceresite ST-83 is widely used for pasting building facades. It has excellent frost resistance, well joins wood, concrete, plaster, brick. After drying, the ST-83 is breathable. Consumption per 1 square. m small, because it is enough to apply a mass of 1 cm thick (this is done with a notched trowel).

The company also produces high-quality adhesive Ceresit CT 85, which is considered universal. High strength and ductility are due to the constituent polymers. But this tool costs an order of magnitude more expensive than the previous one, so builders prefer the ST-83. Both materials are applied in intermittent strips, slightly departing from the edge for better air output.

to contents ↑Bergauf ISOFIX

Bergauf Isofix glue - a mixture of minerals, fillers, cement, sand, plasticizers, special additives. It is applied to any rooms and for external works. Average consumption - up to 5.5 kg / sq. m, a thin layer (3 mm) is required. After dilution, the mixture is viable for 1.5 hours, it is possible to change the position of the plate on the wall for 25 minutes. The glue is sold in 25 kg bags; it can glue extruded polystyrene foam with all kinds of surfaces.

to contents ↑Polyurethane products

Any polyurethane adhesive is seriously different from the dry mixes described above. Often they are called “glue-foam”, “foam-glue”, because the compositions are sold in cylinders, for their use you need a construction gun. They are used in the same way as polyurethane foam. Polyurethane adhesives for EPS are usually used for outdoor applications, they have strong adhesion and are easy to use. Funds dry quickly, are economical, do not respond to changing weather, are frost-resistant.

to contents ↑Tytan Styro 753 GUN

It is produced in cylinders of 750 ml, suitable even for internal work. This polystyrene adhesive is applied in thin strips, then the material is immediately applied to the wall. It can fasten EPSP to the base of plaster, concrete, wood, mastic, cement, and is able to reliably glue polystyrene sheets together.

to contents ↑TechnoNIKOL glue-foam

TechnoNIKOL glue is widely used for fixing polystyrene plates to foundations, walls of houses, roofs, basements, and floors. With the help of glue, the gaps between the insulating plates are also closed. The adhesion of the product is high even where there is mold, high humidity, fungus.

Glue "Penopleks" Fastfix

The tool is considered effective for fastening plates from EPSS to the bases of concrete, aerated concrete, brick, ceramic blocks. Packed in standard cylinders 750 ml. It is characterized by high strength, the quality of adhesion to the base is one of the best among analogues. Glue is incompatible with bitumen compositions, plastic wrap, Teflon.

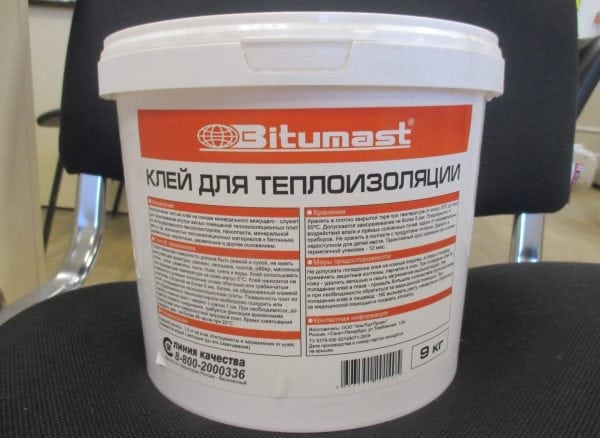

Bitumast glue

Mastic Bitumast in properties resembles a stucco-adhesive mixture, but includes bitumen, which plays a connecting role. The advantage of the glue is its excellent compatibility with extruded polystyrene foam; it adheres to the material without complaints for a long time.The tool also has waterproofing properties, protects the joints of external walls from moisture.

to contents ↑You can mix Bitumast without difficulty, it takes a couple of minutes, no special tools are needed (even a mixer is not required). It is also not necessary to warm up Bitumast before use. The consistency is liquid, so the application is done in a thin layer. The minus is significant - the mastic seizes slowly, it will be necessary to keep the sheets of PPP from slipping for a long time.

Polyvinyl acetate adhesives

Polyvinyl acetate is a transparent elastic polymer, which is obtained by polymerization of vinyl acetate. Such an adhesive is considered universal, since it can hold any hydrophilic materials together. These adhesives do not rot, they prevent the appearance of fungus.

"Moment Joiner"

Universal polyvinyl acetate adhesive, widely used in repair work. It is packaged in containers of 0.1-30 kg, so you can easily pick up the required weight. Moment Stolyar dries quickly, does not corrode surfaces, holds polystyrene foam sheets very reliably.

PVA-MB

Do not confuse the product with ordinary PVA glue. This material is a reliable polyvinyl acetate emulsion with a number of plasticizing additives in the composition. PVA-MB dries slower than the Moment, but the seam is considered stronger. Do not buy too cheap adhesives, PVA is often faked.

to contents ↑Other gluing methods

Some masters try to apply "home" methods of fastening polystyrene plates with other methods. This is not always reasonable.

Polyurethane foam

Using foam fasten any surface, including EPS. The cost of foam is often cheaper than similar glue in cylinders. But the disadvantages of this method are obvious:

- slow setting with the base - plates lying vertically will constantly slide;

- in the glue there are special adhesion-improving additives, which makes it more reliable in detachment than foam;

- polyurethane foam tends to grow in volume, and with the installation of expanded polystyrene this can play a bad role;

- foam peels off the wall faster than glue.

The advantage of foam is the ability to fill the seams between the plates, so it can also be useful in installation.

to contents ↑

Hot-melt adhesive

Thermoplastic adhesives include special substances based on polyamide, ethylene vinyl acetate, which become liquid during heating. As they cool, they harden. Such tools are suitable for working with extruded polystyrene foam, but their cost per 1 kg can be up to 1500 rubles. The price of work, therefore, will not be the lowest. It is more advisable to buy a suitable specialized adhesive and carry out repairs economically, efficiently and reliably.