Veneer - a practical material based on wood, which is a sheet or tape up to 12 mm thick. It is intended for the refinement of inexpensive furniture, doors and other items, giving a beautiful appearance and increasing the strength of products.

- Types of veneer

- Which glue is better to use - types

- Surface preparation

- Material preparation and cutting

- Bonding Methods

- Cold contact method

- Hot gluing

- Cold bonding with extrusion

- Useful tips and tricks

The process of gluing veneers is called veneering (veneering), its implementation is possible even at home, when there is no special press for gluing. It is only important to choose the right glue for the veneer and apply it according to the rules.

to contents ↑Types of veneer

Traditionally veneer is used for gluing MFD, particleboard and other combined materials. Usually, a veneer is understood to be a derivative of natural wood, although some types of it are reconstructed, unnatural and include various synthetic additives.

According to the methods of cutting, the material is divided into the following types:

- tangential - sawing a tree at a certain distance from the core, which makes it possible to create a special pattern at the exit;

- radial - the cut is in the center of the trunk, the canvas is homogeneous, durable, high quality.

According to the processing method, the material may be:

- Shelled veneer. It is produced when the logs are rotated in a special machine, where thin ribbons are cut from the tree. Cutting is parallel to the fibers. Usually, veneers of birch, oak, pine, alder are made this way. The resulting sheets are used for veneering and cladding.

- Sawn veneer. To create it, a high precision machine with up to 20 saw blades is used. The result is thin boards - even with increased wear resistance. Most often, conifers are processed in this way, after which the veneer is used for the production of musical instruments, expensive parquet, multi-layer doors, and exclusive furniture.

- Sliced veneer. It is made only of hard wood (mahogany, oak) on machines with running knives. The layers are cut perpendicular to the fibers, resulting in a thin web. Usually it goes on doors, furniture.

A variety of peeled is veneered veneered on-line. Ready peeled material is sorted, dyed, pressed. After the bars are cut, receiving veneer imitating valuable wood species. It can be glued to plywood, MDF and get original furniture. There is also stone veneer, however, it has no relation to wood and is made from slate.

to contents ↑Which glue is better to use - types

To stick the veneer with your own hands, you need to get good glue. The requirements for it will greatly depend on the size of the product to be glued, its type, and design complexity. For example, for sticking small elements, overlapping sheets tightly, you can use PVA or carpentry, but they are only suitable for perfectly even bases.

If the details are complex, require increased strength and quality of gluing, you need to use tools such as "Kleyberit" (polyurethane adhesive), "Tytbond" (glue for wooden surfaces).Re-gluing - gluing along the longitudinal edges of tightly fitted veneer strips to produce cut sheets - is performed using the most reliable formulations, for example, epoxy adhesives.

All the means by which veneer can be glued are divided into structural and self-adhesive. Structural compounds form a strong adhesion to the surface, their curing begins under the influence of a number of factors (depending on the exact type of glue):

- solvent evaporation;

- UV exposure;

- a chemical reaction with the addition of a hardener;

- cooling.

It is enough to squeeze out the self-adhesive composition onto the part or base, the adhesion is formed when the agent spreads during its subsequent curing. Interaction with the base occurs at the molecular level, causing the "soldering" of materials.

to contents ↑Surface preparation

How to glue veneer? The process is simple, but requires strict adherence to the instructions, otherwise the lining may peel off over time. First you need to properly prepare the work surface: it is impossible to glue the material on an untreated old canvas.

- remove the canvas from the hinges with the help of a mount, a screwdriver (as convenient);

- put the product on the floor, chairs;

- remove all accessories - decor, handles;

- remove the old coating with a sharp spatula, you can also put it under the iron or heat it with a building hair dryer;

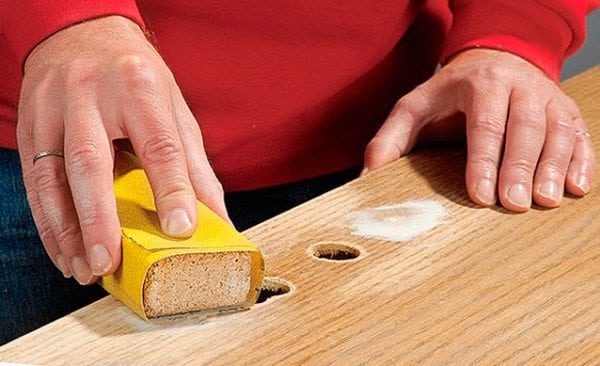

- Sand the canvas with sandpaper or a grinder;

- Cracks, pits, defects should be sealed with special putty on wood, after which they should be covered with wood glue.

Material preparation and cutting

Next, you need to buy material (usually the veneer is sold by footage) and cut it. The rolls must first be straightened so that the veneer becomes even, takes a natural shape. For faster straightening, you can moisten the sheets with a wet sponge, put them between the layers of drywall, plywood.

The canvas needs to be carefully measured. Then you can make a cut, leaving 5 cm of allowance on each side. This will help to avoid problems if the measurement was erroneous. Cut the material with a submersible saw, a plywood knife. It is best to use an electric professional tool, so all sections will be accurate, beautiful. Scissors are not allowed to be used: they provoke the appearance of cracks on the material. The veneer is in the form of stripes, planks must be selected according to the drawing, glued sheets with adhesive tape at the joints and perpendicular lines.

to contents ↑Bonding Methods

Before starting work, you need to mix glue, if it is two-component. Next, you can glue the selected method.

Cold contact method

This technique is much more complicated. For its implementation, you will need contact adhesive for veneer, which sets very quickly due to the minimum exposure time. This technique will not work for beginners, because there will be almost no opportunity to correct inaccuracies in the work. After applying the product to the base, press the veneer to it with force. The important thing is the strong clamping force in the first seconds, which allows not to use the press in the future. Typically, the technique is used for pasting small products.

to contents ↑Hot gluing

Plywooding in this way is simpler. First, a thin layer of glue is applied to both surfaces, which dries up within 10-15 minutes. Then the veneer is laid on the main sheet, melted with a hot iron, or a lapping hammer is used. As the tool heats the adhesive layer, the latter melts and tightly grabs the veneer with the base. In addition, all clusters of air bubbles come out, and the adhesion improves.

For this technique, it is important to use a glue with a thick texture.If it is noticed that it dries too quickly, the base is first sprayed a little with water. Large swellings will have to be carefully pierced, incised, then once again walk on them with an iron.

to contents ↑Cold bonding with extrusion

For this method of veneering, the most commonly used glue is “Taitbond”. It is applied to both surfaces, leveled with a spatula, veneer is applied to the base. After carefully adjusting the position of the material, fix it with a clamp (clamp). Do not remove the clamps until the glue has completely dried, then remove them and check the strength of the joint at the ends of the canvas.

Useful tips and tricks

In order for the result of self-gluing veneer to please the user, you need to follow the advice of professionals:

- veneer textures allow you to create interesting patterns, you can even join different types of wood on one sheet;

- preliminary grinding of the canvas begins with sandpaper with a larger grain, ends with "null";

- grinding is carried out only along the wood fibers;

- when ironing the material with an iron, a layer of cotton fabric is applied from above;

- during ironing, you can not stop, you must constantly drive the iron on the surface, otherwise tan marks will quickly appear on the veneer;

- if the black tan marks did appear, they can be carefully removed with a sharp knife;

- corners, edges of veneer are most conveniently heated with a soldering iron (if the hot gluing technique is used).

Immediately after finishing the lining of the canvas, it must be covered with a layer of varnish. The fact is that the new veneer absorbs moisture greatly, it is important to protect it from excessive swelling. This will help the product to serve faithfully for many years.