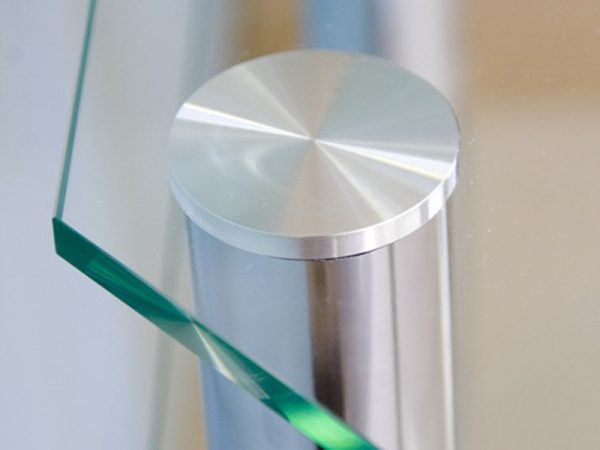

Metal, alloy and glass products are often found in everyday life, in the design of rooms. Metal and glass surfaces sometimes have to be glued together, for example, when repairing household appliances. Conventional glue may not be suitable for this purpose, because for bonding dissimilar materials, the adhesion of the composition should be maximum. Glue for glass and metal must be strong, reliable, high quality, then the joint will not cause complaints.

- Glass bonding to metal - glue selection

- Cyanoacrylate

- Sealant

- Crystal Moment

- Car glue

- Varieties of transparent glue

- How to glue - technology

- Foundation preparation

- Bonding steps

- Using UV Lamps for Bonding

Glass bonding to metal - glue selection

Usually, transparent glue is selected for gluing metal with glass, because it will provide the most aesthetic seam that will be almost invisible externally. This glue quality is especially important if you plan to glue the glass decor to a metal base. But the lack of color, invisibility is not the only requirement for the material. The best glue also has the following properties:

- Strength. If the product will withstand high loads, you should buy glue only with increased adhesion, for example, compositions that, under the influence of UV radiation, become even stronger and stick the parts almost forever.

- Tightness and moisture resistance. Some products play the role of sealant. They are indispensable for bonding glass to metal if the junction is exposed to moisture. Most often, sealants are used when inserting auto glass, self-bonding an aquarium. There are even black sealants that make the future product stylish, with expressive contours.

- Hardening speed. Some products dry in just a few seconds, while others cure for a long time under the influence of ultraviolet light.

If the transparency of the composition is not critical, you can use your own adhesive. Its components are as follows: 2.5 parts of gypsum, lead lead, chalk, 3.5 parts of rosin. This mass is diluted with drying oil, so that a mixture with a consistency of putty is obtained. It will firmly adhere metal and glass, as well as rubber and metal. Among the purchased adhesives, there are various means having unequal composition and properties.

to contents ↑Cyanoacrylate

How to firmly stick dissimilar parts to each other? It is worth using cyanoacrylate or superglue. The tool is better, faster than others, provides reliable pairing, can be single-component, two-component. Drying time of superglue rarely exceeds 5-10 seconds. When buying, you must immediately clarify whether the adhesive is waterproof, since some cyanoacrylates cannot be used in a humid environment. Most adhesives are very easy to use: parts need to be lubricated, pressed to each other.If the composition includes epoxy resin, before work it is necessary to mix the two components of the glue together.

to contents ↑Sealant

How to glue glass to metal if the joint is exposed to regular moisture or even to be in water? A transparent sealant will help here, which gives a high degree of isolation from humidity, withstands the effects of aggressive factors and interruptions in temperature. The sealant has two disadvantages: the degree of adhesion may be lower than that of superglue, and the drying time requires an order of magnitude more. But there are special heat-resistant sealants that can be used to repair stoves, ovens. They do not respond to the action:

- high temperatures (up to +300 degrees and above);

- fat and oils;

- household chemicals;

- frost.

to contents ↑You can use the item after gluing in a day after the repair. Before applying the sealant, it is very important to degrease the substrate well, dry it, otherwise the bond will not be strong.

Crystal Moment

This product is completely transparent, leaves no residue. It is ideal for non-ferrous materials and has a minimum evaporation time. Moment-Crystal can glue not only metal, glass, but also porcelain, ceramics, cork, wood, plexiglass, PVC in various combinations. If excess glue remains on the surface, no solvent is needed. It is necessary to wait until the product dries, then carefully roll it into a small ball, remove. The disadvantage is the unsuitability of “Moment” for products in contact with food.

"Moment-Crystal" is suitable for substrates subject to stress, because the glue line will be quite elastic. After the cessation of exposure, the interlayer returns to its original state without deformation. The glue is one-component, it is convenient to use because it does not need to be bred, to mix components together.

to contents ↑Car glue

What glue should a car owner use when repairing a car? There are transparent and black automotive adhesives, you can choose the color based on the task and the required degree of invisibility of the seam. All adhesives have increased adhesion, are resistant to aggressive environments. Before gluing parts, it is usually recommended to warm them well so that the joint is more reliable.

Varieties of transparent glue

Among transparent adhesives, depending on the basis, the following are distinguished:

- Silicone Usually these are sealants, highly elastic, forming a strong and imperceptible connection. Their polymerization occurs within 12-24 hours.

- Silicate. The composition contains liquid glass, they are durable, heat-resistant, moisture-resistant, also have sealant properties. Perfectly stick together all types of dissimilar materials, suitable even for large surfaces, decorating products.

- Polyurethane Such compositions are most often used for car repairs, equipment, they contain urethane components and other fillers, polymers, plasticizers. The finished connection is very durable.

How to glue - technology

For work, glue itself, carefully prepared parts, means for their degreasing and washing, and rags are required. To heat the surface and its irradiation, you may need a UV lamp, for fixing parts - a press, a vice.

Foundation preparation

Before starting work, it is important to clean the surface, since the presence of even a small amount of rust, dust, dirt greatly reduces adhesion. If the metal is not covered with anything, it is simply wiped with a solvent (acetone, white spirit), you can also use alcohol or vodka. Do the same with glass or wash it with any detergent, thoroughly wash the foam.

to contents ↑After washing, it is worth rubbing the part again with alcohol, because any household chemicals leave a film on the surface.Paint, varnish applied to the metal must be cleaned manually (with an emery cloth) or with a sander, then degrease. Immediately before work, all surfaces dry well.

Bonding steps

The glued parts need to be heated to a temperature of + 40 ... + 50 degrees - this will make adhesion even more reliable. Caution should be observed when warming the glass, it can crack with a sharp increase in temperature. You can not use an open flame, it is better to use the hot air of an ordinary or building hair dryer. Heating will also help to completely dry the parts, remove imperceptible condensate. After cooling, the risk of internal stress of the material will be minimal.

Further recommendations on the work are as follows:

- gently apply glue to both parts to be glued;

- grind the product, forming a thin layer;

- thoroughly work on the edges of the products;

- correlate details with each other, put them together;

- place the product under the press, ensuring uniform pressure.

The press should not be heavy, otherwise there is a risk of damage to the product. It is advisable to remove all the drops that have come out immediately, because not every glue can be rolled up and removed after drying.

to contents ↑Using UV Lamps for Bonding

To form an even stronger joint, it is recommended to use ultraviolet lamps. Be sure to preheat the parts to a temperature of +60 degrees. Then a thin layer of adhesive should be applied, the products should be attached to each other. Next, you need to irradiate the junction with a UV lamp twice. This is done to achieve maximum strength with the seam (after a single exposure, the degree of adhesion will be 70% of the possible, after the second - 100%).

The duration of the lamp will depend on its power. For the first stage, usually 10-120 seconds are enough, for the second - 60-300 seconds. Adhering to the technology without skipping steps will help to securely fix the parts and get the most durable joint that will not be possible to break or break.