Fiberglass is considered one of the most environmentally friendly materials, and also serves for many years without losing properties. Its use is justified for walls and ceilings, it literally transforms the surface to be treated. To stick such a canvas, you need to select the appropriate adhesive for fiberglass. Ready mixes and dry powder are on sale - the choice is up to the buyer.

- Properties and application of fiberglass

- Advantages and disadvantages of fiberglass

- Types of adhesive for fiberglass

- Ready mixes

- Dry powder

- Popular manufacturers

- Fiberglass sticking technology

- Tools and materials

- Preparatory work

- Glass cloth pasting

- Features of gluing fiberglass on drywall

- Fiberglass finish

Properties and application of fiberglass

It is a mistake to consider that fiberglass “spider web” is an exclusively decorative material for interior work. The scope of its application is wide and is not limited to wall repair. In general, fiberglass is a type of fiberglass, a canvas consisting of many glass threads. According to the production technology, the threads are combined with each other and impregnated with modified starch. The same technique is used to produce glass, but the density of materials varies.

The first batch of fiberglass was made from stained glass in Germany, the city of Steinach. Later, the method of producing this material with a non-woven base was improved, additional improving components (resins, modifiers, paper, etc.) were introduced into the composition. Fiberglass has a certain density, which is included in the certificate of conformity of a particular roll, and this indicator determines the scope of use of the canvas. In appearance it is fleecy and rough on the underside, perfectly smooth on the outside. Most often, the canvas has a white color.

The degree of breaking load depends on the density of the material. Thick fiberglass is ideal for reinforcing walls, reinforcing corners prone to destruction. Other areas of application in repair work:

- the basis of the walls for painting, for finishing with wallpaper;

- plasterboard coating, MDF panels;

- waterproofing works;

- anticorrosive treatment of pipes with a sticker on bitumen, mastic.

As the final (finish) coating, fiberglass is not used. It is also not recommended to use it for pasting walls with putty, plaster without priming. Due to differences in texture, the cobweb is often blistered.

In addition to participating in repair work, fiberglass is widely used for the production of building materials and other goods:

- roofing materials in rolls;

- linoleum;

- water panels;

- foam glass;

- glass wool plates;

- molds;

- printed circuit boards;

- drainage structures.

Advantages and disadvantages of fiberglass

The advantages of fiberglass are undeniable. It is absolutely safe for human health, can be used even in children's rooms, clinics, kindergartens due to its eco-friendly composition. Formaldehyde and other harmful substances in the material are not normal. Other advantages of fiberglass:

- high temperature resistance;

- the ability to withstand temperature changes;

- lack of reaction to dampness, the ability to apply in wet rooms;

- lack of accumulations of static electricity and dust on the surface;

- hypoallergenicity;

- application for external and internal works, a wide field of operation;

- lack of an unpleasant smell;

- non-susceptibility to decay, damage by fungus, corrosion;

- high fire safety;

- long service life;

- lack of response to moderate mechanical damage;

- excellent durability;

- vapor permeability.

Important! Fiberglass is not only easy to glue on the walls and ceiling with special glue. It is quite suitable for painting work - you can apply paint to it, and up to 10-15 times. Walls after such finishing do not need special care. Fiberglass is suitable for different substrates - plasterboard, concrete, wood.

With all the advantages, the disadvantages of fiberglass are also worth mentioning. Non-certified material of poor quality may still contain harmful substances: phenols, formaldehyde resins. This is the so-called first-class fiberglass, which is forbidden to be used in residential buildings.

When buying, you need to specify the code and type of material in advance, and also check it for smell - a good fiberglass does not have it. Another disadvantage of a poor canvas is its brittleness, inelasticity, which will not allow gluing correctly and with a decent result.

The disadvantages include the complexity of dismantling fiberglass. It is problematic to remove it from the walls, ceiling, and ceilings, since it is impregnated with glue and firmly connects to the base. How much does the material cost? The price also can not be attributed to the pluses, because high-quality paintings have a high cost.

to contents ↑Types of adhesive for fiberglass

Fiberglass can not be glued to every wallpaper glue. The usual composition based on simple starch is not suitable, because the glue must have high strength, excellent adhesion. You should choose the tool on which the purpose is indicated "for glass, fiberglass, cloth of glass filaments."

Some craftsmen prefer to glue material on PVA. This is also possible, although professional tools, except PVA, have other reinforcing additives.

All adhesives are sold in two forms: ready-made mixtures, dry powders. They have different physical properties, but are used for the same purpose and are not inferior to each other in quality. There are also fiberglass, already impregnated with glue, they only need to be wet.

to contents ↑Ready mixes

It’s very easy to stick wallpaper with such means. They are already divorced, fully ready for operation. Usually the compositions are sold in packages of 5-10 kg (liters), but there are also larger plastic buckets for professionals. The consumption of 1 m2 of adhesives is most often equal to 200-300 g.

Important! When purchasing a product, you need to look at the expiration date. An expired product reduces the adhesion rate and other technical characteristics.

Fiberglass from such a tool begins to exfoliate or goes in bubbles. After opening, the glue must be used faster so that it does not have time to deteriorate.

Many ready-made formulations are made on the basis of polyvinyl acetate or polyacryl - synthetic substances in which polymerization occurs after the evaporation of water. It is very popular to glue fiberglass on acrylic adhesives. The consumption of glue is small, because it is applied in a very thin layer. The adhesion of the material is the highest, the base will be strong, reliable.

Ready-made polyvinyl acetate adhesives are made on the basis of the usual PVA, which is sold in every office supply store. The product has no aggressive and harmful substances, it is convenient to use, has no smell, can be used in children's rooms.

For fiberglass, special substances are additionally introduced into the glue composition - colloidal additives, polyvinyl alcohol, plasticizers, which strengthen the composition and prevent its separation. Also among the constituents there are fungicides that prevent the fungus from multiplying. As a thickener, hydroxyethyl cellulose is used - a food additive that regulates viscosity and fluidity.

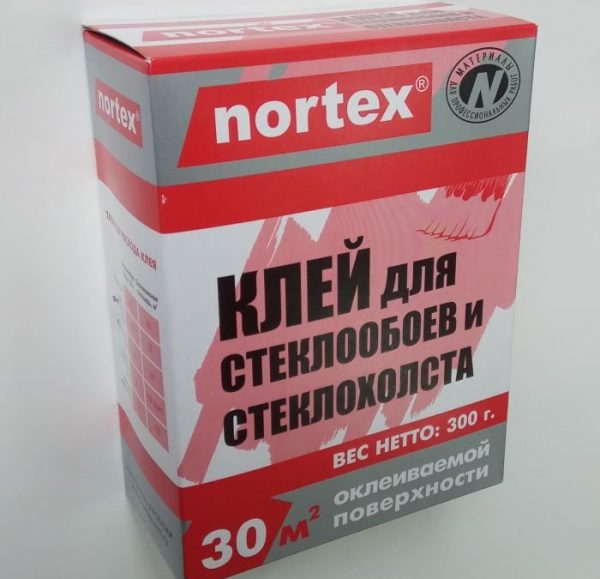

to contents ↑Dry powder

Gluing surfaces with fiberglass can be done using a different type of adhesives - dry mixes. They need to be pre-cooked - diluted with water in a certain proportion, which is always indicated on the package. Such funds are cheaper, but extra time is spent on preparation.

The composition of dry mixes includes:

- modified starch;

- methyl cellulose;

- dry PVA;

- technological additives.

After drying on the wall, the composition should not be re-wetted, so water-based paints should not be applied to fiberglass. The nature of the operation of the room also does not imply high humidity, although some adhesives have moisture resistant additives. In any case, the detachment of the fiberglass will not happen, but it can warp a little.

The composition of the funds should include special components that can provide excellent adhesion and a long service life of coatings. Plasticizers are necessarily present - they make the adhesive elastic, do not allow it to crack after drying. Fungicides prevent the appearance of fungus, mold, do not allow bacteria to destroy the created adhesive layer.

to contents ↑Popular manufacturers

Some brands of adhesives for bonding fiberglass have earned special trust from users. Here are the main ones:

- Bostik (Bostik). It occupies a leading position and is characterized by an optimal ratio of price and quality. It is best to use glue in dry rooms. Not only fiberglass can be glued to it, but also vinyl, non-woven wallpaper.

- Kleo (Cleo) Ultra. Designed specifically for fiberglass, it is characterized by the highest quality, durability, ease of dilution, low consumption, environmental friendliness.

- Wellton (Wellton). Ideal for subsequent painting of fiberglass, equipped with additives to enhance fire safety, environmentally friendly. Fiberglass can be washed regularly - the glue is not afraid of moisture.

- Oscar (Oscar). Very economical glue - 0.5 kg is diluted with 10 liters of water. It’s easy to cook, it does not form lumps. The finished solution is stored for almost 2 months without loss of properties. Consumption is economical - only 250 g per square meter of area.

- Quelyd (Kelid). The product can be applied manually and by machine, it completely dries in just a day, is stirred without lumps.

- Pufas (Pufas). This is a popular brand that creates building materials using new technologies. The range of brands includes many adhesives for wallpaper, including fiberglass. Means are frost-resistant, contain fungicides.

- Bolars Fiberfix (5 kg). This glue is designed specifically for fiberglass, is sold in finished form, dries quickly, can significantly reduce repair time.

Some users glue the edges, joints of fiberglass with sealants, liquid nails (for example, Ob, Moment). This is not necessary, high-quality glue for fiberglass materials can cope with any joints, reliably protecting them from detachment.

to contents ↑Fiberglass sticking technology

Many are interested in which side the fiberglass is glued. Its seamy side always twists in a roll inward, it will have to lie against the wall. To get a good result, you need to follow the correct technology for gluing the canvas.

Tools and materials

To work, you need to prepare such devices:

- glue, fiberglass;

- long-nap roller, brush;

- a tray for glue;

- a bucket for diluting glue (if it is dry);

- construction mixer or wooden stick;

- plastic spatula;

- steel spatula;

- sharp knife;

- tape measure, pencil;

- level;

- stepladder (if necessary);

- respirator, gloves, tight clothing;

- masking tape.

Preparatory work

A wall, ceiling, floor or other surface must be carefully prepared. They are cleaned of dust, dirt, large cavities should be sealed. If lime was applied to the walls, they are wiped several times with a wool rag with water. The floor is covered with cellophane, windows and doors are covered with masking tape. Markings are made on the surface with a pencil to make it easier to stick on the material.

Important! The first roll is turned upside down. Cut into pieces of the desired length, previously everything is well measured. It will be necessary to stick the material with an overlap, which is taken into account when marking and cutting.

Next, the container with the finished glue is opened. Dry powder must be prepared for use, taking into account the manufacturer's recommendations. Actions will be as follows:

- Take water at room temperature, but not too warm, in a measured volume.

- Pour dry glue into the water (pour along the edge of the dishes, immediately mixing the composition).

- Knead thoroughly the entire solution, preferably with a construction mixer or a drill with a nozzle.

- Allow the product to brew for 5-10 minutes.

You can get to work. During breaks, the container must be tightly closed so that the water does not evaporate.

to contents ↑Glass cloth pasting

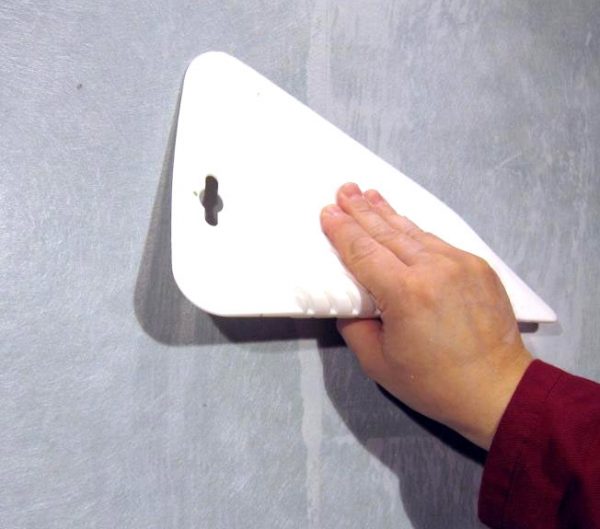

To glue the first canvas, you need to take the finished cut and glue. Using a paint roller or plastic spatula, apply the product on the surface of the ceiling or wall (the width of the glue is slightly greater than the width of the glass by 5-6 cm). Put a strip of fiberglass on the wall, starting from the top, gently smooth to remove all air bubbles.

The edges do not need to be pressed too tightly, this will make gluing the next strip easier. It is applied immediately after completing work with the first overlap. It is important that the picture on the canvas coincides (if any).

In uncomfortable areas (at corners, around outlets), a brush is used to apply glue. The glued fiberglass is leveled with a small spatula. Sometimes it happens that the edge of the fiberglass is broken up, so sticking a second lap strip causes the appearance of tubercles at the junction. Immediately after gluing, these tubercles are cut with a clerical knife in the longitudinal direction, pieces are removed, as a result, the joint will be applied butt to butt.

Dry the material without drafts by closing windows and doors. This will improve the adhesion of the adhesive.

Important! Only after complete drying the fiberglass can be primed and subjected to further decoration. Work with the material must be subject to safety measures, protecting the skin and respiratory tract. Otherwise, glass particles can cause health problems.

to contents ↑

Features of gluing fiberglass on drywall

Before gluing, drywall must be carefully primed. The joints are pre-puttyed so that they go flush with the main part of the GCR. But before the fiberglass sticker, the plastered areas are treated with sandpaper, primed, otherwise the glue will be absorbed high. Then they work similarly to the general order.

Fiberglass finish

After complete drying, you can begin to paint the surface. It is allowed to putty it or not to do it, but in the latter case, the paint will acquire the structure of a spider web. If smooth walls are required, puttying cannot be avoided, for which finely dispersed compositions are used. Immediately before painting, it is necessary to make a primer, which will save paint consumption. Acrylic or latex paint is suitable for painting. Acrylate formulations may also be used. Paints are applied by roller, brush (in the usual way), the use of a spray gun is allowed.

After the walls have dried, the room can be operated by wet cleaning as needed.