Mosaic PVC panels are an excellent budget solution for decorating a bathroom or kitchen. This material is an alternative to expensive ceramic tiles, so it is very popular among builders, repairmen.

- Mosaic panels in the interior

- Types of panels for mosaic

- Panel Properties

- Assembly and installation

- Bonding Procedure

- Installation on the crate

The properties of PVC are not worse than that of ceramics - the wall covering does not allow moisture, is wear-resistant. Before gluing the PVC-mosaic panel, you need to familiarize yourself with its features, select the optimal installation method.

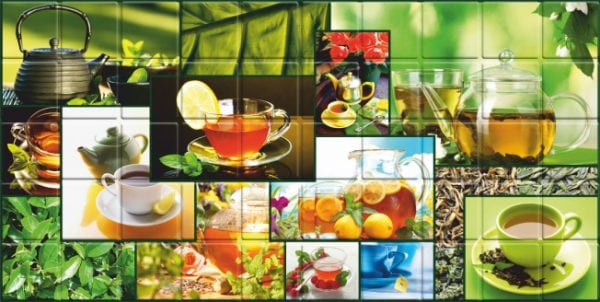

to contents ↑Mosaic panels in the interior

Polyvinyl chloride is a special type of thermoplastic plastic made up of a vinyl chloride polymer. This plastic is the raw material for many finishing materials, giving unlimited scope to the designer’s imagination. On sale there is a huge assortment of PVC panels for mosaics. They can be used for cladding the entire bathroom, only some walls, in separate stripes. In addition to the bathroom, such wall panels can be glued in:

- bathroom, toilet;

- shower cabin, SPA;

- hallway, pantry;

- a kitchen in the workspace;

- country house in the country.

The surface of the panels is styled as a mosaic, it also has small square sections separated by seams. You can choose the cladding for the apartment, depending on individual preferences. Products under a tree, a stone, with abstraction, geometry, a flower ornament are realized. In stores there are even panels for gold, silver, pearl, marble. Shades of coffee, turquoise, marine, crystal, malachite and others are especially popular.

to contents ↑Types of panels for mosaic

Sheet panels vary not only in appearance but also in size. Here are the main types:

- Narrow typesetting type. They have connecting locks, reminiscent of lining. The length is 2.10-3 m, the width varies from 25 to 50 cm.

- Sheets, or rectangular wall plates. Their size is 485 * 960 mm, but there are other formats, including those for individual orders.

- Square. The side of such a mosaic is 30-100 cm.

The outer coating of this finishing material can be glossy, matte. Another difference between products is their price. Domestic manufacturers produce panels of the economy segment, but there are more expensive ones. Foreign companies present similar products at a high price. The best brands are:

- PlastDecor is the largest manufacturer of construction products from foamed polyvinyl chloride, which produces mosaics using modern equipment. Products of this brand are in most specialized stores.

- Dekoplast is an equally well-known manufacturer, constantly producing the latest types of PVC products. All products have certificates, very high quality.

Panel Properties

Plastic wall cladding is characterized by high performance, ease of use, which explains its popularity. The properties of PVC panels are unique:

- Water resistance. The surface of the sheets is even, it has almost no pores, so water does not leak inside. This eliminates the risk of fungus, mold, browning.

- Soundproofing properties. If you use the material for the bathroom, kitchen, walls will pass an order of magnitude less sound.

- Fire safety. Compared to other finishing materials, plastic mosaic has a higher flammability threshold.

- Convenience of installation. The panels are easily sawn, processed, they can be drilled, cut, milled, bent, even cut out a curly contour. Even a beginner can stick a mosaic on the walls.

- Resistance to damage. Products are not easy to scratch, spoil, they wash perfectly from any stains, do not respond to household chemicals, alkalis, acids.

to contents ↑The service life of the panels is at least 15 years, while their decorative properties are amazing. Typically, products are painted with the most abrasion-resistant dyes, due to which they do not fade, do not fade. Plastic cladding imitates different types of expensive surfaces, while being accessible to everyone.

Assembly and installation

The decorative panel will help to hide the imperfections of the walls, with its help it is possible to hide even significant flaws. Nevertheless, uneven walls, pits and bulges can cause delamination of the material. Before gluing it, it is better to choose the glue suitable for plastic and carefully prepare the walls. There are two ways to install the material, they are described below.

Bonding Procedure

Gluing the mosaic onto the wall is the simplest and most popular solution. The surface must be plastered, leveled, primed. Large differences will lead to the expansion of thin plastic, so all irregularities must be eliminated with putty.

The gluing procedure is as follows:

- keep the material at room temperature for 12 hours or more;

- drip any degreaser onto the plastic, wipe;

- apply glue pointwise around the entire perimeter and in the center;

- lean the sheet against the wall according to the marking;

- press, hold the right time (according to the instructions for a specific adhesive).

Suitable for installation are “liquid nails”, polyurethane or silicone glue. Since gaps inevitably appear between the individual elements, silicone sealant is used to conceal them. For the same purpose, you can use a special molding. Cutting the mosaic is possible with strong scissors or a construction knife.

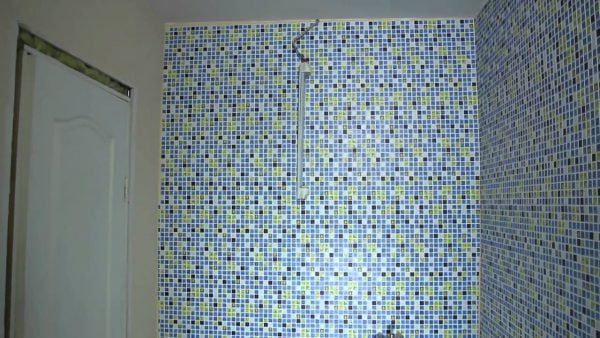

to contents ↑Installation on the crate

If the wall is too uneven, it is not possible to put it in order; another way of installing panels is allowed. To do this, you need to make a crate of wooden bars, treating them against mold fungicide. The distance between the individual bars is 50 cm, the crate is attached to the wall with nails, dowels. Next, you can stick the mosaic in the same way.

In the free space between the crate and the wall, it is allowed to hide the wires, lay insulation, etc. Caring for plastic panels is straightforward. They can be washed, wiped with a damp cloth, without fear of spoiling.