Warming the house is not a difficult task now - on the market there are many types of modern thermal insulation materials, as well as adhesives for fixing them. The most often used mineral wool in the form of plates - it has many advantages: from environmental friendliness to low cost. Adhesive for mineral wool should ideally fit the base material, not violate its vapor permeability and take into account the possibility of vibration, movement of load-bearing structures.

- Basic criteria and requirements for glue

- Types and properties of adhesives

- Dry mixes in bags

- Liquid solutions in containers

- Polyurethane Adhesives

- Application of adhesive for mineral wool boards

- Overview of adhesives for mineral slabs

- Mineral glue EK Thermex

- Glue Ceresit CT 180

- Glue Ceresit CT 190

Basic criteria and requirements for glue

Usually, home insulation is done on the outside - it is more profitable and more convenient. Therefore, when selecting glue for mineral wool, it is necessary to take into account the possibility of its use precisely for facade (exterior) works. Before buying an adhesive, it is important to carefully read the instructions and make sure that it meets the following requirements:

- Plastic. The higher quality plasticizers and modifying additives are present in the composition, the lower the risk of cracking and destruction of the adhesive joint.

- High adhesion coefficient. Glue should reliably grasp with mineral wool, as well as with the base of the wall - brick, stone, wooden.

- Permeability to air. If the glue does not have this property, condensation will accumulate inside, as a result, the microclimate in the room will be disturbed.

- Frost resistance. Since adhesives for mineral wool boards are used outside, in winter they should easily withstand freezing and subsequent thawing without compromising strength. Also on sale there are "cold-resistant" adhesives that can be applied at temperatures below +10 degrees (they will be required if the insulation is not in the summer season).

- Optimum pour point. Fast drying of the composition means a decrease in the complexity of the work and a reduction in the time for their implementation.

- Sufficient solution viability. The higher this indicator, the easier it is for the master to work, because you can immediately cook large portions of glue in volume.

- Possibility of applying an adhesive layer of any thickness. With uneven walls, some areas have to be covered with a thicker layer, on others a layer of 3-5 mm is sufficient. Glue should not have restrictions on this indicator. The consumption of high-quality products does not exceed 4-6 kg / square meter.

to contents ↑Usually adhesives for heaters are made on the basis of polyurethane or cement mixed with quartz, as well as a number of synthetic components. Despite the difference in composition, all products have the above properties, although they also have a lot of differences.

Types and properties of adhesives

Adhesives can be specialized and versatile. The former are suitable only for basalt-based mineral wool, glass wool, others are suitable for gluing most known heaters - polystyrene, foam, as well as reinforcing mesh. By structure and appearance, adhesives can be liquid, dry, in cylinders.

Dry mixes in bags

Building mixtures for gluing mineral wool are sold in dense paper bags of 5-25 kg.The composition includes cement, quartz sand, synthetic resins, plasticizers, other additives and adhesion improvers. Before use, the composition is diluted with water, the result is a pasty solution. It is especially suitable if the walls of the house are uneven, and they must be leveled before use, because a thick layer of glue smooths out defects.

Before buying, it is important to make sure that the mortar is suitable for outdoor use and has good frost resistance. Here are the main properties of such adhesives:

- excellent adhesion to the insulation and mineral base of the walls;

- sufficient ductility, elasticity;

- the presence of reinforcing fibers in the composition, due to this - resistance to mechanical damage;

- vapor permeability;

- resistance to cold, humidity, temperature differences;

- environmental friendliness.

Liquid solutions in containers

Such solutions are already implemented in finished form. It is very convenient to apply them, because you do not need to spend time on diluting glue. But after opening the packaging adhesives have a limited shelf life, so it is better to purchase small cans. There are other disadvantages: the high price of liquid adhesives, as well as their unsuitability for smooth substrates. In fact, it is worth using the compounds only on wooden surfaces or masonry.

to contents ↑Polyurethane Adhesives

Glues or glues-foams based on urethane resins are sold in the form of cylinders; to use them, the packaging itself with a dispenser is enough or you need to buy a glue gun. Polyurethane compounds are considered universal, since they have a high level of adhesion with any insulation and base. Here are the advantages of such adhesives:

- ease of use, no need for dilution, the presence of complex devices;

- serious reduction in working time;

- providing an additional heat insulating layer;

- the ability to work in any conditions, even with high humidity, low temperature outdoors;

- lack of harmful additives;

- resistance to moisture, good vapor permeability;

- long service life without loss of basic qualities.

Application of adhesive for mineral wool boards

Before starting work, prepare the foundation. There should be no serious defects on it, all large holes, cracks, irregularities must be repaired. It is also important to maximally clean the wall of dirt, grease, although this is not always possible. Severe contaminants can degrade the adhesion of the composition to the base, so they are washed off with water under pressure. Strongly absorbent substrates should be primed 1-2 times, using special primers for outdoor use. Just before attaching the mineral wool, make sure that the base is completely dry.

The degree of adhesion of the adhesive can be checked in advance in this way:

- take a small piece of insulation;

- stick it on the wall;

- after 72 hours, try to tear off - if the cotton wool is disconnected strictly along the lines of glue application, then adhesion is sufficient.

Mineral wool slabs must also be prepared before work. All roughnesses exceeding 2 mm in size are polished from them. For this purpose, use sandpaper or a grinding machine.

Dry building mixes are diluted with water according to the manufacturer's instructions. Add the powder to the water, and not vice versa, otherwise the tool will go lumpy. After mixing the glue with a construction mixer, it is ready for use. When using polyurethane adhesive, shake the bottle well enough and insert into a special gun.

The procedure will be as follows:

- first, glue is applied to the base, after which a reinforcing mesh or other reinforcing material is glued (this step is optional);

- glues-foams are applied around the perimeter of the insulation in strips of 2-5 cm wide, as well as in the center and in the voids every 30 cm;

- solutions are applied with a spatula with wide tapes (10 cm);

- apply mineral wool to the prepared base, firmly press the stove, iron, tap to expel the air;

- the distance between the plates should not be more than 2 mm, larger gaps need to be shed further with foam;

- for reliable fastening, many use dowels, but they can be used only 72 hours after the adhesive layer is completed.

Overview of adhesives for mineral slabs

On sale there are a variety of compositions for fixing insulation, they are produced by almost every modern manufacturer of adhesives and building mixtures. The most popular ones are described below.

Mineral glue EK Thermex

The tool is used to equip thermal insulation systems, suitable for exterior and interior use. It is ideal for attaching mineral wool, expanded polystyrene, reinforcing heat grids to concrete, brick bases. The glue is characterized by plasticity, frost resistance, high level of adhesion. Its main technical characteristics:

- color - gray;

- base - cement;

- the life of the solution is 3 hours;

- consumption - 5-6 kg / sq. m;

- layer thickness - 3-8 mm;

- temperature during work - + 5 ... + 30 degrees;

- adhesion - 1 MPa;

- frost resistance - 75 cycles;

- operating temperatures - -50 ... + 70 degrees.

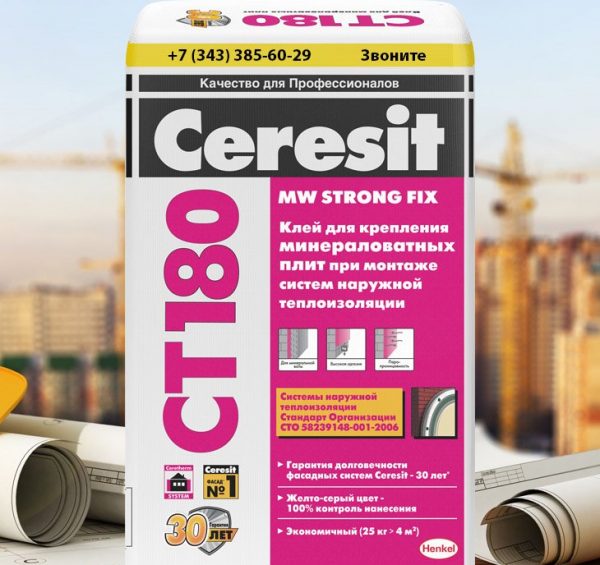

Glue Ceresit CT 180

The dry mix “Ceresit” is produced on the basis of cement, polymer fillers and modifiers, and is used to fix mineral wool insulation on the outside of the house. You can apply the product at temperatures above 0 degrees, it has high adhesion with most bases (0.8 MPa), is resistant to tearing. Good vapor permeability ensures stable and efficient steam removal, which inevitably forms during the evaporation of liquids. Other properties and technical parameters of the adhesive:

- environmental Safety;

- consumption - 5-6 kg / square meter;

- the density of the dry mixture is 1.4 kg / sq. dm;

- the density of the finished mixture is 1.6 kg / sq. dm;

- water norm - 5-5.75 liters per 25 kg;

- solution viability - 2 hours;

- open time - 20 minutes;

- frost resistance - 100 cycles;

- operating temperatures - -50 ... + 70 degrees;

- the color of the finished adhesive layer is yellow-gray.

Glue Ceresit CT 190

This product is ideally suited for basalt heaters, for example, Izovol cotton wool. The main scope of application relates to the external bonding of mineral wool boards, but internal use is also possible. Glue is available in the “winter” and “summer” versions, which allows you to use it at any time of the year. "Ceresite ST 190" is suitable for independent fastening of plates, as well as for gluing in combination with a reinforcing fiberglass mesh.

The advantages of the composition are as follows:

- long service life (several decades);

- excellent adhesion to mineral wool and base;

- the presence of reinforcing fibers in the composition;

- high impact strength;

- resistance to atmospheric factors, moisture;

- environmental Safety;

- vapor permeability;

- elasticity.

Like other adhesives, this product is sold in 25 kg bags. Its consumption is approximately 6 kg / square meter. The open time of the solution is 40 minutes, operating temperatures range from -50 to +70 degrees. Adhesion to concrete is 0.6 MPa, to mineral wool - 0.5 MPa, frost resistance - 75 cycles.

All adhesive products, when used correctly, will help quickly, without the need for special skills, to attach thermal insulation. Mineral wool is an inexpensive and high-quality version of home insulation, and in combination with good glue, it will serve for many years.