There are several types of adhesives on the market of building materials - universal, polyurethane, epoxy and several others. Rubber glue invented many years ago does not lose popularity. With this composition, you can easily glue any rubber products, as well as leather, plastic and other materials.

- Key Features

- Types of Rubber Adhesive

- Properties and specifications

- Application Methods

- Cold

- Hot

- The choice and technology of work with glue for rubber

- The subtleties of the process

- Surface preparation

- Glue application

- Rubber Adhesive Manufacturers

Key Features

This type of glue is often called liquid rubber, because it is made from natural rubber - a natural resin with powerful adhesive properties. Instead, synthetic resins can be used in the production of the substance. The rubber component for the production of glue is diluted in chemical solutions, depending on the brand and the exact type of product they vary. As solvents, as well as fillers in the rubber glue may be present:

- aromatic carbons;

- chlorine compounds;

- ethyl acetate mixed with nefras;

- polystyrene;

- artificial latex;

- resins;

- metal oxides;

- amines;

- sulfur;

- stabilizers - ethanol, diethylamine.

As plasticizers that improve the properties of glue, mineral oils, phthalates, lanolin, and carboxylic acid esters are introduced into the composition. In general, each manufacturer develops its own formulation of rubber glue, reducing or increasing the share of natural rubber in it and adding more and more new substances. In any product there is always a minimal set of components - a crosslinking agent, a curing agent and a solvent.

Glue can connect a variety of materials, apply it for domestic needs, at a construction site, in repair. They are repairing bicycle chambers, rubber boats, leather products at home, using it for shoes, closing holes, and defects. It is also possible to fix linoleum, carpet, and other floor coverings with this glue. Some types are permissible to work even on glass, tile, metal. Industrial compounds are used to cover rackets for table tennis, textiles (for example, gloves), vacuum products, in the manufacture of furniture, auto parts.

After hardening, the adhesive in appearance and properties becomes very similar to rubber. The tool is transparent and opaque, which must be considered before buying. It remains elastic even as it cures, for which it is appreciated by the craftsmen. Cons of rubber adhesives also have:

- not too aesthetic-looking adhesive seam;

- unpleasant odor due to the presence of solvents;

- the need for good ventilation due to toxicity;

- difficulties with drawing;

- the appearance of burns on the skin with sloppy work;

- risk of damage to instruments after the end of the process or difficulties with their washing.

Types of Rubber Adhesive

Each glue for rubber can be included in one or another group according to the type of curing:

- Unvulcanizable formulations. Curing occurs when solvents evaporate.

- Self-vulcanizing agents. Freeze with atmospheric moisture. There are one-component, two-component.

Glues are divided by volume of solids into groups A and B.In the first group of funds, the share of solids is 6-8% (they are the most elastic), in the second - 8-12%. The composition of adhesives is divided as follows:

- On natural rubber. Means are of natural origin, but are not able to withstand high temperatures. In industry adhesives are used to a limited extent.

- Chloroprene. The composition of adhesives includes divalent metal oxides. They are highly durable, heat resistant, easily withstand the effects of adverse factors. Tools are considered the best when working with metal and glass.

- On nitrile butadiene rubber. Such adhesives are very waterproof, which expands the scope of their use.

- On silicone rubber. Means are used for bonding rubber, have increased heat resistance.

- On styrene butadiene rubber. Usually they go to the production of adhesive tape, for artwork, their adhesive abilities are low.

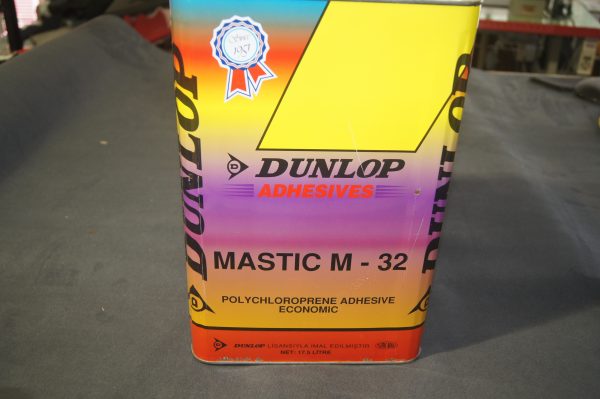

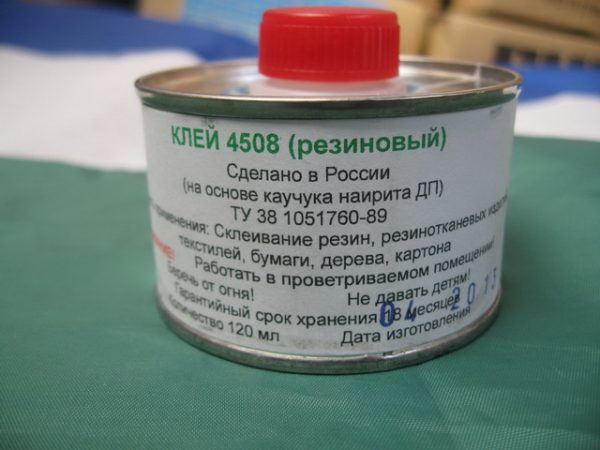

to contents ↑Even adhesives can be divided into products for home and industrial use. If the first are produced in bottles, tubes, the second - in cans, buckets, barrels and are applied using special tools. In shape, all adhesives can be divided into conventional formulations in tubes, thick pastes (mastics), as well as sealants, which additionally have sealing properties.

Properties and specifications

The difference between rubber glue and other adhesive compositions is that it forms a seam that preserves plasticity. This product resembles elastic silicone sealants, which after drying also remain semi-solid, like raw rubber, due to which they do not crack during operation. The average viscosity of a VZ-246 viscometer for rubber adhesives is 10–40 seconds.

Rubber based adhesives have high tensile strength (from 1.09 MPa). And special high-strength compounds withstand the most severe loads, they are used at a construction site, in car repair. Most adhesives are waterproof, therefore they are suitable for repairing products that come into contact with moisture and even stay in water for a long time - boats, shoes. There are petrol and oil resistant products that are insoluble in petroleum products (for example, adhesives of the brand KR-5-18, BR-10).

On sale you can find quick-drying rubber adhesives, the curing of which occurs more quickly than with conventional formulations. Most often they are used in emergency work and in large-scale repairs, so as not to spend a lot of time drying. Universal adhesives combine all the basic properties of the listed tools:

- work at -50 ... + 70 degrees;

- water resistant, oil resistant;

- elastic;

- Do not harm base materials.

Application Methods

Bonding can be carried out by hot and cold vulcanization, which determines the drying time of the adhesive.

Cold

This method practically does not differ from gluing products with conventional adhesive compositions. The process is carried out at room temperature. After applying the adhesive with a thin layer, wait 20 minutes, repeat the procedure, then connect the parts. Next, leave the subject to dry completely (from day to 2-3 days).

to contents ↑Hot

Hot bonding involves heating the surface with the adhesive applied to + 70 ... + 160 degrees, after which the parts are connected to each other. At the same time, the drying speed of the seam is reduced to 3 hours, and the quick-drying compositions completely dry in a few minutes.

The choice and technology of work with glue for rubber

For repair or production of products, it is necessary to choose high-quality rubber glue. The more flexible the finished structure will be, the more flexible the composition should be. It is also important to take into account the humidity and operating temperatures of the product, the subsequent load, the structure of the materials (hard, soft, porous). Rubber-based glue should not harm the main material, show chemical aggressiveness to it.

to contents ↑The subtleties of the process

To reliably glue two surfaces or seal a defect, you need to make sure the glue consistency is optimal. It usually thickens when stored improperly or when it has expired.If in the second case it is better to discard the composition, then in the first you can dilute it a little. How to dissolve too thick glue? Nefras or benzene are usually suitable, which are added until a homogeneous mass is obtained.

Other useful tips when using glue:

- the temperature in the room should not fall below +5 degrees, otherwise the speed of solidification of the composition will sharply decrease, as well as the quality of the adhesive joint;

- rubber compounds are flammable, work with them is permissible only with careful observance of fire safety rules (it is forbidden to be near any sources of fire);

- deviate from the manufacturer's instructions, it is impossible to reduce the exposure time of the adhesive joint to operation;

- for hot gluing, it is most convenient to use a building hair dryer, which very quickly heats the glue to the required limit;

- with hot bonding, harmful fumes are intensely released, therefore it is possible to work only with good ventilation and wearing a respirator.

Surface preparation

When preparing, before gluing, remove any dirt from the products. It is recommended to sand smooth materials (sandpaper), this will help strengthen the adhesion of the glue to the base. After that, both parts must be degreased before gluing, for this they must be wiped with alcohol, acetone or another rapidly evaporating liquid. Surfaces must be completely dry before work.

to contents ↑Glue application

Thick adhesives are applied with a small spatula, more liquid - with a brush. The thickness of the adhesive is about 2 mm. After applying it to 2 layers, immediately press the parts against each other or heat the glue or allow it to dry slightly in air - depending on the manufacturer's recommendations.

to contents ↑When repairing a boat, a thinner adhesive layer (1 mm) is made, then a piece of gauze is applied, another layer is applied, and only then a patch is attached. The glue that has come out is immediately removed with a knife, spatula. The product is aged 1-2 days or more, preferably in a vice or under pressure.

Rubber Adhesive Manufacturers

A popular glue is "Moment-1" - a quick-drying composition that is ideal for rubber, wood, metal, plastic, glass. It can be applied in a very thin layer, so the consumption will be minimal. It is necessary to press surfaces to each other only 15 seconds, and then it is necessary to leave details before full drying.

Other examples of well-known brands of rubber adhesives:

- Glue 88 N. It has the consistency of sour cream, it is easily diluted with benzene. It is recommended to dry the first layer of the product for 5-6 minutes, then apply the second and put the product under the press.

- Glue 88 CA. As a basis includes rubber and artificial resins, it is divorced by nefras and ethyl acetate. Designed for bonding glass, wood, concrete, rubber, foam, foam.

- Glue 4508. Super moisture resistant, flexible, highly sticky. It is used in the manufacture of textiles, special suits, rubberized fabrics. It glues boats and other PVC products well.

- "Radical". This composition is especially appreciated by fishermen: because of the ability to withstand a large load, the influence of water and freezing temperatures can be used in boat repair. The tool is not even afraid of sea water.

- "Gum". This glue is most often used in the repair of leather goods, shoes, automobile and bicycle cameras.

- Plasti Dip. It is a paint with the addition of rubber, which is applied to car parts to optimize the appearance and enhance the protective properties.

Rubber adhesives allow you to securely fasten products from many materials, they are literally absorbed into the surface, and the resulting seam is not destroyed for many years. The cost of adhesives is low, repairs will not cost dearly, which only enhances their demand.