In the market of building materials, one of the most popular is considered corrugated board. This material has a wide scope. It is used for roofing, building partitions and external structures. In order not to develop corrosion, the profiled sheet is painted. Therefore, many people are interested in how to paint corrugated board and what method is better to use for this.

- Characteristics of corrugated board

- Airless paint technology

- Pneumatic spraying method

- Combined method of painting profiled sheet

- Electrostatic painting technique

- Powder coating method

- Powder Coating Method

- Paint selection

- Conclusion

Characteristics of corrugated board

Profile flooring is a durable and wear-resistant modern material. As a rule, it is presented in the form of a galvanized profiled sheet of metal. To improve the protective characteristics, the material can additionally be coated with a special polymer mixture. At the same time, a large selection of colors and sizes of profiled sheet is presented on the market. Thanks to this, today it is possible to choose this roofing material so that it covers the entire roof area without overlaps.

In the production of corrugated board, rolling equipment is used, which allows you to achieve the necessary sheet parameters. The professional sheet in its physical characteristics is similar to metal tiles. It mainly differs from metal tiles in a different form and lower price. The thickness of the profiled sheet can be different and on average it is about 0.5 mm.

In the production of corrugated board, the metal sheet is coated with a layer of zinc. Next, the sheet is primed for the subsequent application of a color coating of polymeric materials. Cold-rolled steel is used directly for the manufacture of profiled sheets. In addition, such a roof may additionally be covered with plastisol, pural or PVDF.

Modern painting techniques:

- pneumatic;

- airless;

- combined;

- electrostatic;

- powder.

These methods differ in quality, economy in terms of paint consumption and speed of painting.

to contents ↑Airless paint technology

The method of painting corrugated board by airless method provides for a sharp decrease in pressure at the outlet of the stream of paints and varnishes from the nozzle. This method uses air as a brake to reduce aerosol speed. Due to this, the paint is evenly distributed over the painted surface.

Advantages of airless technique:

- lack of fog from paint;

- maximum painting performance.

to contents ↑The disadvantage can be considered relatively less high-quality decorative coating compared to using a pneumatic spraying method. In this regard, this technique is more suitable for painting a flat surface.

Pneumatic spraying method

The pneumatic spraying method involves the use of compressed air. The method consists in using a spray torch consisting of an aerosol. The following factors affect the quality of pneumatic painting:

- features of the shape of the torch in the form of an aerosol;

- the ratio of air to paintwork depending on the area of the spot;

- speed and flow parameters of paint particles.

Among the disadvantages of the pneumatic spraying method is low profitability due to the large volume of spray mist. This is due to significant losses of the paint solution. Therefore, reinforced hoods should be used for pneumatic painting.

to contents ↑Combined method of painting profiled sheet

The combined technique is that increased pressure is used to move the paint and form a torch. Therefore, a stream with the same intensity comes out from the nozzle as when using an airless one.

Using a special device of the spray head due to the influence of compressed air, additional atomization of the particles of the paint coating is carried out. As a result, the most perfect form of the spray torch is formed. This method is perfect if you need to paint the fence from corrugated board.

The main advantage of the technique is the achievement of optimal paint parameters. At the same time, the method is quite complicated and requires the use of advanced painting equipment.

to contents ↑Electrostatic painting technique

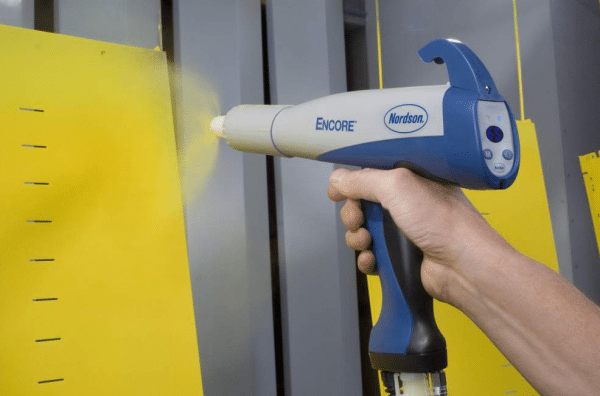

One of the most modern is the electrostatic spraying technique. It is based on the ability of microparticles of paint to acquire an electrostatic type charge. As a result, the particles can move towards the line of the electric field formed between the spray gun head and the working surface.

This technique is considered the most cost-effective in terms of consumption of paints and varnishes. Among the disadvantages of the method, one can single out the difficulty of painting surfaces with a non-standard relief, for example, with recesses or sharp edges of the profiled sheet.

to contents ↑Powder coating method

The most popular today is the powder technique for painting a profiled sheet. This method allows to achieve a different level of gloss and relief on the painted surface. The technique is considered the most modern and effective for applying a protective or decorative layer to corrugated board.

Today, there are practically no analogues of such technology. The main difference between the powder coating method is the complete absence of solvent. The powder here consists of rubber microparticles and various pigments.

to contents ↑Powder Coating Method

- The preparatory phase, including degreasing the surface, training the sheet and creating a film of phosphate.

- Coating the cleaned surface with a special powder paint. Due to its unique composition, all small particles of paint adhere to the surface.

- Polymerization, which provides for uniform melting of the powder mixture in special furnaces. The process is carried out for ten minutes at a temperature of about 200 degrees.

to contents ↑An important procedure in the preparatory phase is the selection of colors, which is made on the PAL scale. At the same time, today you have a huge selection of different shades that can be selected according to individual criteria.

Paint selection

When choosing a paint, you need to remember that it is best to carry out external painting of corrugated board polyester paints. For interior painting of the premises, it is desirable to use high-quality epoxy-polyester paints and varnishes from foreign manufacturers, which are absolutely safe for humans. It is advisable to choose paints from European manufacturers, for example, from French, German and Italian companies.

During operation, various scratches and chips may appear on the corrugated board. This not only negatively affects the appearance of the material, but also its protective anticorrosion properties. To eliminate these damage, it is advisable to use sprays for tinting corrugated board.

to contents ↑Conclusion

Thus, various methods can be used for painting corrugated board, which differ in their cost-effectiveness, quality and complexity of implementation. As a paint for a profiled sheet, it is best to use alkyd enamel, which compares favorably with other paints and varnishes for metal. She is very resistant to negative external influences and is not afraid of daily and seasonal temperature differences. In order for the paint to fit tightly on the coating, it is necessary to properly prepare the surface, making it as dry and clean as possible.