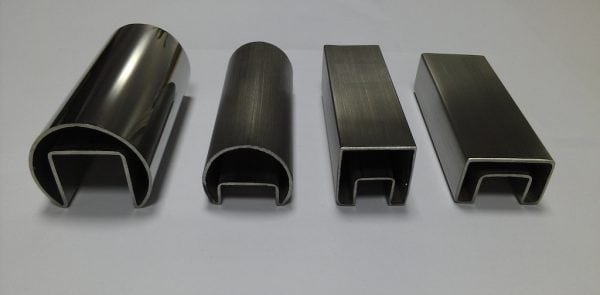

Due to its properties, stainless steel has become a very popular material. It is used for the manufacture of various products. Initially, they may have a matte, polished or painted surface. It is worth remembering that stainless steel is a material that has poor adhesion. Because of this, the answer to the question of how to paint a stainless steel has its own nuances.

Staining Features

For painting stainless steel, two types of paint are used: powder and liquid (sometimes in aerosols). With their help, you can give the product almost any color, for example, black, white, etc.

Powder painting material

Powder paint is recommended to use by many experts. It can be applied using a spray gun. After application, the product must be melted in a chamber with a high air temperature (2000 ° C). The result is a film having a lot of advantages:

- The product becomes resistant to corrosion.

- The film formed by the paint prevents scratches and other similar damage.

- The surface painted with such a dye is not afraid of temperature changes and exposure to chemicals.

- The paint layer is perfectly even. Thanks to this, the surface looks neat.

- If powder dye is combined with fillers, various textures, colors, and effects can be obtained.

When applying powder paints to stainless steel, several effects can be obtained:

- glossy or matte;

- flat or, conversely, surround;

- gold or silver;

- imitating wood or marble.

By the way, there are such coloring compounds that help paint any other surface under stainless steel.

If you look in general, the technology of using powder paint has many advantages:

- It must be applied in only one coat.

- It has a high level of adhesion, which is especially suitable for stainless steel.

- No waste remains during the painting process. Powder that has not been used can be collected and applied another time.

- The workflow takes very little time.

Painting stainless steel with a powder dye consists of several stages:

- First you need to thoroughly clean the working surface of settled dust and dirt.

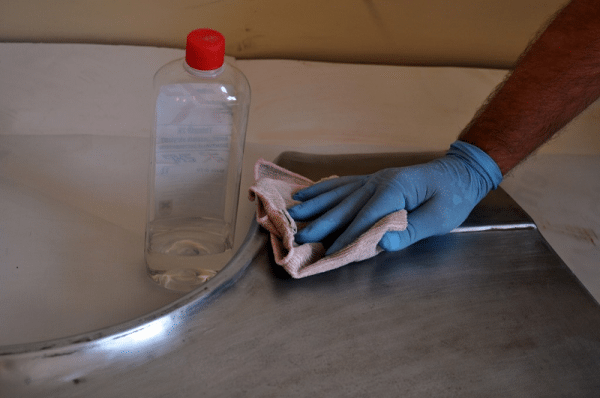

- Apply a special composition to the stainless steel that can degrease it.

- Further, it is recommended to apply a layer of a substance, which after drying forms a strong protective film (usually phosphate).

- The next step is washing the surface and drying it.

- Now the product needs to be put in a chamber in which it will be covered with paint.

- The final part of the work is surface melting using high temperature.

This technology has one significant drawback. It lies in the fact that to carry out such painting at home is not possible. The process requires expensive equipment.

to contents ↑Liquid Coloring Compounds

If there is a need to paint the stainless steel at home, you can use liquid paint, which is often available in the form of aerosols. The workflow is similar to the processing of ordinary steel. Differences are only in preparatory procedures.

Preparation should be taken as seriously as possible. To a greater extent, it depends on how durable the coating will be.

You need to perform it approximately according to this plan:

- To clean a working surface by means of an emery paper. The ideal option is to use a special grinder. The nozzle should have an average level of grit. The machine must be set to the highest speed. Do not press too hard on the surface. The movements should be smooth and accurate.

- It is recommended that the cleaned surface be treated with degreasers based on alkalis or acids. If there were none at hand, a degreasing solution can be prepared independently. For this you will need ordinary baking soda and water. To prepare a 100 ml solution, you will need 4 g of soda and 96 ml of water. This is a fairly effective way of surface treatment. In addition, it does not require additional costs for the purchase of chemicals.

So it is correct to apply liquid paints or aerosols:

- First, the coloring composition must be thoroughly mixed. If necessary, pour it into a spray bottle.

- Next, the painting process begins. It is very important to pay attention to how the tool is held and moved. The sprayer or aerosol spray can must be kept strictly perpendicular to the working surface. The optimum distance between them is 20 cm. The tool must be moved in a straight line.

- So that over time the paint does not begin to lag behind stainless steel, it is necessary to apply it in two layers. The second is applied after the first has completely dried.

- To make the surface more durable and shiny, you can cover it with a layer of varnish.

Oxide film

Separately, it is worth mentioning the painting of stainless steel by creating an oxide film on it. The essence of the method is that the surface is treated with plasma with a very low temperature. The workflow is performed under certain conditions. One of them is the presence in the atmosphere of at least one gaseous substance with oxygen atoms in the composition. The result of this staining is an oxide film, which changes the color of the surface, while leaving its original appearance intact. If the product was matte or shiny, it will remain so.

The color that results will depend on several factors:

- Voltage arising between the anode and cathode. In this case, the role of the anode is played by the steel itself or an object made of it.

- The current density in the anode.

- The time when the process occurs.

- Distances between cathode and anode.

The cathode can be made of any metal. The most commonly used are aluminum and titanium.

Such electrochemical staining makes it possible to give the stainless steel yellow, red, blue, blue-green, pink and other shades.

By the way, if you change the patterns used during the process, you can make various patterns on the steel surface. This is possible due to the fact that the plasma acts on different sites for a different amount of time.

So, painting stainless steel products is not so difficult. At home, this can be done with liquid paint, sometimes available in the form of aerosols. The enterprises usually use powder dyes. They create a protective layer on the surface that protects against corrosion and external influences. The use of coloring compounds together with special fillers allows you to experiment with texture and effects.