Coloring of plastic is rather rare, since there is always a large selection of finishing panels and plates made of plastic materials. Nevertheless, sometimes the imagination of manufacturers is not enough, and the consumer paints a part of the plastic plate in a different color on his own. All this, however, does not last long, and therefore over time the question arises: how to remove old paint from plastic.

- Coating Removal Principle

- Methods for identifying various types of household decorative plastic

- Marking

- Nature of burning

- Immersion in water

- Preparatory operations

- Technology and consistency

- Immersion in solution

- Original way

Coating Removal Principle

Most of the known methods to wash old paint - mechanical and thermal - are not suitable for plastic surfaces. In particular, when heated, some plastics can undergo thermal degradation: warp, emit an unpleasant odor. The mechanical method will cause permanent damage to the plate from the source material (unless, of course, this is the goal). There remains a chemical way to remove old paint.

The choice of active substance to wash the old coating depends on the physico-chemical characteristics of the object - whether it be windows, shelves or decorative small forms. Therefore, first of all, it is necessary to find out which plastic is supposed to be processed. If there are no unnecessary finishing plates left, you will have to experiment on subtle parts of the product.

to contents ↑Methods for identifying various types of household decorative plastic

Available methods for determining the type of plastic mass are as follows:

- Decoding of the plastic marking on the back of the product plate. It is mainly used for imported decoration panels for windows and plastic interior doors.

- Method of igniting the material: the nature of the burning also helps to establish the appearance of the plastic.

- The density of the material, for which the part is immersed in water.

Consider these methods in more detail.

to contents ↑Marking

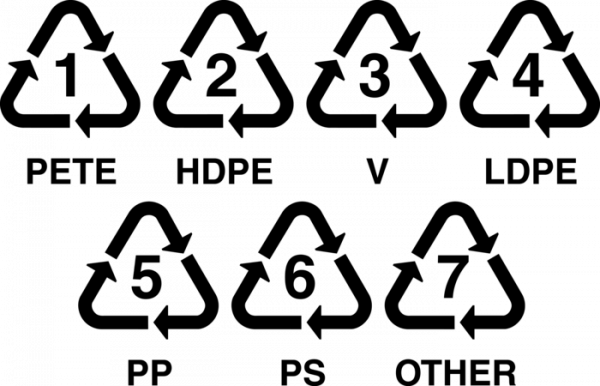

According to the international classification of plastic materials that are used in everyday life for the manufacture of window panels, door slopes, etc., all plastics have a specific digital designation. It is indicated in a triangle extruded on the back of the part. The international identification codes for the plastics used are as follows:

- polyethylene terephthalate - PET, the number in triangle 1;

- polyethylene, respectively, low and high density, - LDPE and HDPE, the numbers in the triangle 4 or 2;

- polyvinyl chloride - PVC, number in the triangle 3;

- polypropylene - PP, the number in the triangle 5;

- polystyrene - PS, the number in the triangle 6.

The manufacturer of the plastic element may, unfortunately, use a material not from the above list. Then in the designation will be the number 7, which will not tell us anything. In addition, small producers can generally ignore the requirements of the Plastics Processors Association, according to ASTM D7611, which is marked above. In such cases, you will have to apply the second method from the recommended list.

to contents ↑Nature of burning

The burning of plastics occurs in various ways.The table below shows the characteristic differences and features of the process:

| Type of plastic material | Nature of burning | Published odor | Extra features |

|---|---|---|---|

| PET / PET | Burning flame with soot; if material is removed from the flame zone, combustion ceases | Cutting | When burning it becomes soft |

| Polyethylene | Burning with a bright bluish flame, without the formation of soot | The smell is similar to the smell of molten paraffin | When burning, drips and drops form |

| Polypropylene | Burning with a bright bluish flame, no soot | A pungent odor similar to that emitted by molten wax or rubber | Elongated filamentous fragments often form from the melt |

| Polystyrene | Bright, smoky burning that produces soot flakes | Sweetish | |

| PVC | It practically does not burn, smokes, self-extinguishes, if removed from the flame zone | Distinct smell of chlorine | A zone of bluish-green color is visible in the flame |

| Polyamide | Burns, forming a blue flame | Smell of burning hair or feathers | Cracks and swells when burned |

| Polyurethane | When burning forms a smoky blue flame | Cutting | The drops of melt after sticking are sticky and greasy to the touch |

| ABC | Bright, smoky burning that produces soot flakes | Cutting | |

| Ftoroplast | It doesn’t burn, it just charred | Very sharp | |

| Polycarbonate | It burns poorly, self-extinguishes when removed from the flame zone | Sweetish, reminiscent of the smell of flowers |

Immersion in water

If for some reason it is impossible to test the plastic for burning, it is worth trying the third method. All that is needed for him is a basin of water. Only polyethylene (any) and polypropylene will float in it. Fluoroplastic will sink most quickly, PET / PET and PVC a little slower, polyamide and polystyrene last the longest on the surface.

After identifying the plastic, you can begin to choose the optimal chemical reagent in order to wash the old paintwork.

to contents ↑Preparatory operations

In addition to the type of plastic, one should also find out the type of composition with which it was painted at one time. For instance, wash off water-based paint will be the easiest. It is enough to heat the surface, which was painted with water-based paint.

For water based paints, surface temperatures of 60-75 ° C are sufficient. Such work must be carried out in the warm season, since with a high temperature contrast, the water-based paint will be removed, but the surface of the plastic product may receive permanent deformation.

For other types of paints, washing them by surface heating of the plastic is ineffective. Therefore, the surface of the window and door that is being prepared for cleaning must be thoroughly cleaned of dust and dirt, and then stock up:

- a respirator (in extreme cases - a gauze bandage);

- a set of cotton swabs;

- tassel for removing old paint from a window or the plane of the door leaf.

The work must be done with rubber gloves, since all solvents are toxic and can cause skin diseases. The room in which washing work will be carried out must be effectively ventilated.

to contents ↑

Technology and consistency

Washing old paint from the plastic surface of a window, door or other element in the home interior is done like this.

Immersion in solution

It is easiest to wash the paint with polystyrene. Flushing is performed as follows. The panel from which you want to remove the coating is immersed in a 20% solution of caustic potassium or sodium (you can use a 50% aqueous solution of caustic soda). Rinsing is better, for greater clarity, to conduct in a glass container.

After 4-5 hours, any paint (including acrylic, rubber or oil) will begin to bubble and move away from the surface of the plastic. For the final flushing of the old coating, it is best to use an old toothbrush with increased rigidity.

With small surface areas of the window or door that are to be washed off, any solvent can be used - solvent, acetone or white spirit. It is easiest to rinse with ABC grade plastics.

Compositions such as brake fluid and water-soluble compounds for cleaning sewage pipes of the “Mole” type are effective enough to remove old paint from plastic.

Although the mechanism of washing is different for them - brake fluid separates the coating layer by layer, and "Mole" simply dissolves the paint - the final effect is completely comparable.

After applying the chemical composition with a cotton swab or a glass stick soaked in warm water, gently wash off the remaining layers and areas of paint that has separated from the plastic.

Actively removes all types of paint from plastic plates - from water based emulsion to alkyd enamel - methanol. However, the use of such a composition is distinguished by two features:

- Methanol is toxic.

- After its application, the cleaned surface of the window, door, etc. rinse immediately with warm water, as traces of oil remain on it, and the cleaned product itself may turn yellow over time.

Original way

So you can remove the old paint from a plastic product having a three-dimensional configuration. To do this, it is enough to cover the material with a layer of liquid glass or silicone sealant. When dried, these substances loosen the paint and thereby contribute to its separation from the original surface.

The curing time of silicone is usually 12-24 hours (depending on temperature and relative humidity in the room). After solidification with a sharp knife or a medical scalpel, a deep incision is made on the surface. Perform this procedure very carefully so as not to damage the original plastic base of windows or doors.

After that, the silicone “mask” breaks and can be removed with the paint. If the surface has been previously primed, the operation will have to be repeated, and then the product should be completely washed.

Following these recommendations in good faith will allow you to carefully and efficiently wash plastic from old paint.