Do-it-yourself powder painting of metal parts is not so difficult, the main thing is to know all the subtleties and act strictly according to the instructions. In addition, there is a significant cost savings on the face, because the prices in the salons for painting parts of metal mechanisms or spare parts for cars are quite high.

- Equipment required

- Stove manufacturing

- Painting tool - gun

- Little things you can't do without

- Technology

- Preparatory stage

- Powder coated part

- Polymerization

Equipment required

In order for the process of self-painting to practically not differ from the factory, it is necessary to choose a suitable place where the work will be carried out.

When the premises are found, you need to collect and prepare the necessary equipment:

- oven for polymerization (drying);

- DC voltage source (about 25 kV);

- powder paint sprayer (gun);

- LMB.

Accuracy and a little experience will not interfere with work. But if it is not there - it does not matter, following the instructions, you can avoid most mistakes and get a pretty decent result.

to contents ↑Stove manufacturing

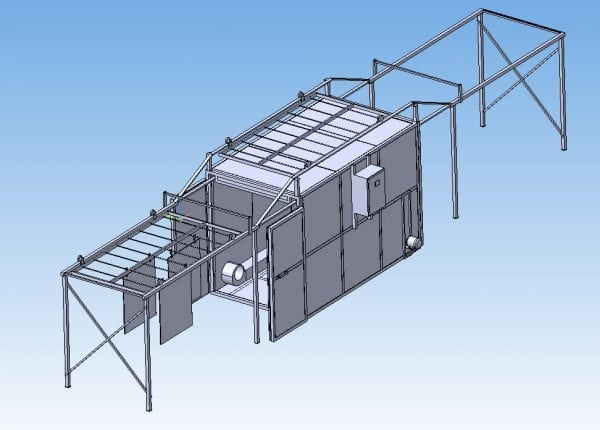

Polymerization is an important step in the curing of powder paint. If this item is omitted, paintwork will not be held on metal surfaces. Therefore, equipment such as a furnace - it is also called a polymerization chamber - is necessary in the first place. This thing is expensive, so you can do it yourself, from improvised materials. We will need (the polymerization chamber will have dimensions 2x1x1 m):

- profile pipe;

- non-combustible thermal insulation (basalt plate);

- sheet metal (can be ordered by size);

- tangential fan;

- TENY.

The furnace assembly instruction consists of the following steps:

- Weld the frame from the profile.

- Put a heater in it.

- Sheet metal sew the walls. Trim everything outside with plaster fiber.

- For convection in the chamber, install a tangential fan by welding it with a narrow output and a wide entrance.

- Insert the fan into the camera. It will take air at the top, drive it through the heating elements, expel it at the bottom, and then distribute it throughout the chamber.

- TENY establish along parallel walls and connect on distribution on phases.

- Close the heating elements, leaving the fan open, the main part of which should be located outside the chamber (so as not to melt the winding).

- Install an electrical panel. True, it is better to entrust this work to a specialist.

The resulting equipment - the polymerization chamber - will have a capacity of 12 kW for heating and 6 kW in operation.

to contents ↑Important! The energy source in such powder paint drying ovens can be not only electricity, but also natural gas and diesel fuel.

Painting tool - gun

To apply powder paint to a product, a special device is required. This is an electrostatic spray gun or tribostatic powder spray gun. But to buy expensive equipment for the sake of rare use is not advisable. Since in our case everything is made with your own hands at home, such a device can be made for about 10 minutes. Such a gun is easy to use, cheap and practical. The transition from one paint to another takes a few seconds.

How to make a powder paint gun:

- Take a regular plastic 1.5 liter bottle. The main thing is that it is dry and clean.

- Fill it 1/3 with powder paint, tighten with a metal stopper.

- Make small holes in the cork. The more holes, the better the application. Strip the cork outside of the burrs remaining after piercing.

- Connect the positive wire to the plug from the high voltage source.

For this purpose, you need a converter that can deliver 25,000 volts of direct current. Such are used in stun guns, lighters for gas stoves, boilers and columns. They can work from batteries or accumulators, converting 3-6 volts to the required 25 kV.

Use caution when working with high voltage. It is better to entrust the assembly of the converter to a qualified electrician.

After all the manipulations, a pretty decent pistol is obtained.

to contents ↑

Little things you can't do without

Before starting the painting, care must be taken to ensure that all operations take place under ideal conditions:

- Great lighting needed. Use fluorescent lights. Powder paint adheres well to a conventional lamp.

- Need good ventilation with two motors (input and output). In addition, you will have to wear a gauze bandage, and preferably a professional respirator.

- One will have to invent a method for collecting powder paint residues. At the initial stages, use an old powerful vacuum cleaner.

When everything is carefully prepared, you can start painting with your own hands the necessary details.

to contents ↑Technology

The process of painting metal parts with powder compositions can be divided into three stages. This is surface preparation, direct staining (spraying) and fixing the result (polymerization).

Preparatory stage

He is the most important. The result of work depends on how well the surface is prepared for painting. Follow the instructions below:

- Take an ordinary clean cloth and clean the entire surface of the workpiece from dust and dirt.

- With sandpaper or specialized metal brushes, clean the areas with corrosion.

- Degrease the part with solvent, this will increase the adhesion of the surface to the paint.

- Primer. To do this, coat the product with a paint based on inorganic substances. Thanks to this layer, the risk of penetration of air, as well as moisture under the dried paint, is nullified.

- Apply a layer of sodium and chromium nitrate on top of the part. This process is called passivation. It is carried out so that rust does not appear during the preparation of the part for painting. All actions are quite simple, so you can do everything at home with your own hands.

- Dry the workpiece in a makeshift oven.

to contents ↑Important! If the part is too complicated, heavily soiled and corroded, soak it in an alkali solution.

Powder coated part

The next stage after the preparatory stage is direct staining. Everything is quite simple here: place the part in the spraying compartment, attach and fix the negative wire from it to your power source. If you turn on our converter and bring the bottle with a metal stopper to the part at a distance of 20-30 mm, we will see sparks slip, which means that the voltage is enough to apply powder paint.

To do this, we press on the bottle so that part of the powder along with air is blown out of the holes in the cork. Under the influence of high voltage, the paint particles are electrified and adhere to the product to be painted.

Part of the powder will still crumble to the floor, so lay the newspaper down to collect it later.

Advice! If by means of painting it is planned to achieve the component's resistance to ignition, buy fire-retardant coatings for metal (Negorin, Polistil and the like).

After applying the powder paint, the process of creating a cured polymer layer begins.

to contents ↑Polymerization

The essence of this process is that the painted part is installed in a special furnace. There she is exposed to high temperature for a certain period of time.

This will require a self-made powder paint polymerization furnace. In order for the process to go without overlays, the following conditions must be observed:

- Follow the guidelines designed for each specific paint.

- Ensure even heating of each part.

- Observe the exact polymerization time. After it expires, remove the part from the chamber and leave it in the open air for complete cooling.

The application of this method of staining with powder compositions is ideal for those who like to do everything with their own hands. It’s quite a long time to make an oven for polymerization on your own, but it’s a significant cost saving on your face and a high-quality coating.

Where in the garage to get 25 kV ???

PS: but someone will read and run to search.

Hint - there was such a tension in lamp TVs ... Look!

High voltage inverters are not used much where. For example, in Chinese shocker lights that run on 18650 batteries. The converter itself costs about 200 rubles and 25kV is not the limit, there is also 1000 kV.

Why break the shocker? - Ali has small blocks with high voltage. They make air ionizers, electronic lighters for gas stoves, the same shockers, etc.