Concrete floor in recent years can be found in private homes, industrial facilities and so on. This coating is quite durable and wear-resistant. However, a similar floor does not look too beautiful. In order to make it more presentable, aesthetic enamel for the floor is used. A correctly selected composition will help not only to make the floor beautiful, but also improve its performance.

- Concrete floor distribution

- Modern paints and enamels for concrete

- Acrylic paint

- Acrylic silicone paint

- Epoxy paint

- Polyurethane Enamel

- Urethane Alkyd based paints

- Dry acrylic paint

- Preparation of the basis for staining

- Conclusion

Concrete floor distribution

Concrete floors are most often used in basements, on the terracesin garages and balconies. It is here that the flooring is required maximum strength and resistance to mechanical stress. At the same time, it is not recommended to leave the floor uncovered, since it is contaminated quite quickly. Today, the best option for decorating and extra protection is acrylic enamel for concrete floors.

to contents ↑Modern paints and enamels for concrete

Various enamels and paints are used to protect and improve the aesthetic characteristics of the concrete floor. The most popular types of paints:

- acrylic;

- polymer;

- rubber;

- epoxy;

- acrylic silicone;

- urethane alkyd.

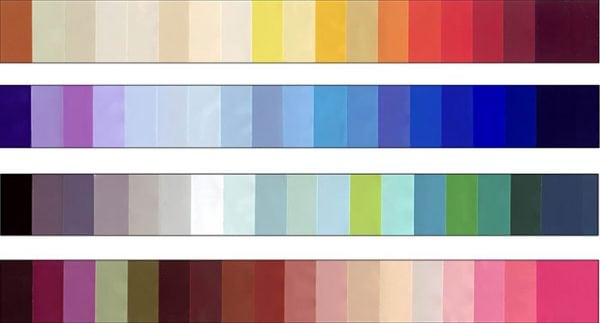

These paints can be made in different colors, which will allow you to choose the best option for any interior.

Acrylic paint

The acrylic composition is made on the basis of acrylic resins with the addition of various pigments of organic and inorganic nature. Such impregnation is applied in two layers, despite its hiding power. Of the positive operational qualities, high resistance to humidity and sharp temperature fluctuations can be noted. Also, acrylic paint can be made in a variety of colors and textures. They are glossy, matte and semi-gloss.

As a solvent, a special diluent or ordinary water is used here. Therefore, if you are looking for how to paint a concrete floor, then acrylic paint can be a great option. After applying to the floor surface, the coating can be used after two days. When applying this type of paint usually does not cause any special difficulties. However, this composition cannot be applied to old epoxy and polyurethane coatings.

Acrylic silicone paint

These paints include components such as acrylic copolymer and silicone-based resin. The use of these compounds involves dilution with water by twenty percent. As a result, using one liter of paint, you can paint a surface of 5 square meters, which ensures optimal composition consumption. Using this solution, painting the concrete floor will become more economical.

This type of composition, like acrylic, must be applied in two layers. The time between application of the ink should be more than three hours. During this time, the surface dries quickly to the extent that it can be walked on.That is, it is a quick-drying paint, which is one of its main advantages. Among the shortcomings of acrylic-silicone compositions can be noted a low degree of resistance to abrasion and poor colors.

to contents ↑Epoxy paint

Epoxy paint for concrete floors is very popular. This is a two-component composition that must be mixed before staining. For mixing, use a special mixer. At the same time, a reinforcing base in the form of an additional layer of paint with 20% dilution should be applied to the floor surface. This will be a kind of primer treatment. After this layer, several more layers of paint are applied.

You can walk on the floor painted with epoxy in a day. However, for the coating to fully harden, wait at least five days. Epoxy paint is highly resistant to abrasion. The main disadvantage is the limited color scheme, which includes only a few colors.

to contents ↑Polyurethane Enamel

Modern polyurethane paint for concrete floors provides reliable protection against any negative influences. This coating is often used for painting industrial floors. A distinctive feature of the composition is the maximum degree of protection against erasure and other adverse effects.

This is very wear resistant paintwhich is ideal for outdoor use. Therefore, if you want to protect your floor covering from wear and tear and do not know how to paint a concrete floor, then a polyurethane compound may be your choice.

Urethane Alkyd based paints

The basis for these paints is alkyd resin. It has an even greater hiding power than acrylic compounds. However, to obtain the highest quality coating, double application of the composition is necessary. The time interval between the application of the first and second layer should be at least 24 hours. After applying the last layer, the floor will be ready for use in a day. However, it may take more than a week to completely harden the surface.

Urethane-alkyd paints are no less resistant to abrasion than polyurethane. Therefore, floors painted with this composition can be used as long as possible. The use of this type of paint involves dilution with white spirit to obtain a 10% solution. Manufacturers offer a wide range of colors, which is suitable for both outdoor work and indoor floor painting. The most popular urethane-alkyd paints:

- gray

- golden;

- yellow;

- brown.

At the same time, the surface of the floor painted with such a composition will always be glossy.

to contents ↑For some, this is the only significant drawback of urethane-acrylic paints and varnishes.

Dry acrylic paint

In addition to the above liquid formulations, modern manufacturers offer original dry paints based on acrylic. They have the appearance of flakes, which make the concrete coating more durable and beautiful. At the same time, the color scheme of dry acrylic compositions is quite extensive, which makes them an excellent option not only for outdoor work, but also for painting floors indoors.

Before applying such paint, the floor should be treated with a special resin, which acts as a primer. Until the resin has frozen, colored cereal is poured onto it. They must be evenly distributed on the floor to get a high-quality painted surface. After the resin with the flakes harden, the coating is brushed to remove insufficiently fixed particles of the composition.Then the floor is varnished. The floor painted in this way will be ready for use in a day.

Preparation of the basis for staining

High-quality painting of the concrete floor involves a preliminary stage of surface preparation before application. First of all, you need to remember that after laying concrete, it must stand for a long time at a temperature of no more than 20 degrees before applying paint. It is better that this period is at least three months. If time is running out, then you need to try to hold the concrete for at least one month. Ideally, before painting, the moisture content of the concrete coating should not be more than 5%.

Humidity is measured using a special device that measures moisture. In addition, any film is suitable for this purpose. You need to put a small piece of film on the floor and fix its edges with tape. After a day, the film is removed and moisture is determined by the presence of condensation on it. If condensation has formed, the concrete floor is not sufficiently dried and is not yet ready for painting. In this case, it can be additionally dried using a heater or provide good ventilation in the room. The second option is possible only if there is a high temperature on the street. Accordingly, for outdoor work in warm weather, it is also suitable.

If you intend to paint concrete that has already been in use, then it should be carefully checked for chips, cracks and greasy areas. Cracks and chips will have to be treated with a special repair solution, and a cloth with a solvent can be used to remove fat. All accumulated dust must be removed from the dry floor. To ensure maximum adhesion of the paint, it is advisable to further treat the surface using a sandblasting machine. Only after all the preparatory work has been completed can the concrete floor be painted.

to contents ↑Conclusion

Thus, manufacturers offer a wide range of paints for concrete, which differ in their performance characteristics and a variety of colors. Whatever composition you choose, before painting it is necessary to conduct a full preparation of the concrete coating.