Pigments for paints are finely ground powders diluted with special substances and added to paints and varnishes. Multi-colored paint (color) is produced by mixing different pigments.

- Pigment colors

- Types of pigments

- Natural pigments

- Mineral dyes

- Organic Dyes

- Artificial pigments

- Ultramarine

- Cinnabar

- Pigments and properties of paints

Pigment colors

The following pigments can be used to form different colors:

- white - chalk, lime or white;

- yellow - crown, ocher;

- blue - ultramarine, azure;

- red - red or lead red lead, mummy, cinnabar;

- green - chrome or lead greens.

Types of pigments

Pigmenting substances are divided into natural and artificial. Naturals are also divided into organic and inorganic. There are relatively few natural substances, but they are used actively in construction, since their use is cheaper than the production of artificial components.

Natural pigments

Mineral dyes

Natural-based pigments are extracted from metals and oxides. Among the sources for obtaining dyes include such inorganic elements with the corresponding colors:

- iron oxides (yellow, brown, red);

- manganese (yellow, purple, brown);

- chrome (green);

- cobalt (blue);

- copper oxides (emerald, red, bright green);

- antimony (yellow);

- ocher (pale yellow, golden, dark yellow, red on ignition);

- Mars (light brown, dark brown);

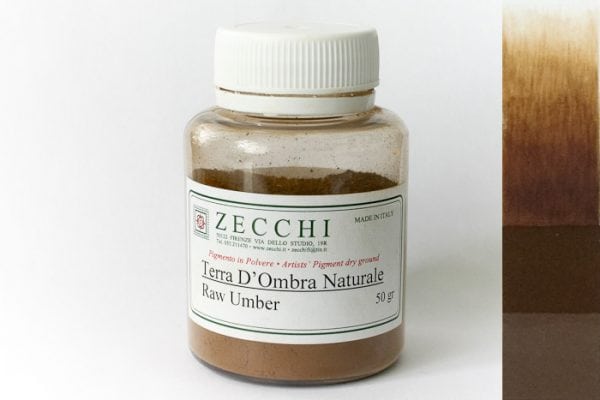

- umber (reddish brown, greenish brown);

- van dick (brown);

- ultramarine (blue).

Mineral dyes characterized by high strength, resistance to light, good miscibility and compatibility with binders.

Characteristics of some inorganic dyes:

- Dry ocher. It is extracted from clay minerals that are colored with hydrated iron oxides. The color of dry ocher is yellow, tan. Ocher is used as a coloring matter in the manufacture of cement mortars used to create decorative plasters. Also used in the manufacture of silicate and adhesive paints. Ocher formulations are well suited for painting concrete, metal and wood products. The pigment is durable, hiding power, resistance to light and alkalis.

- Natural Siena. Clay coloring matter yellow. It looks like ocher, but sienna contains more iron oxide and silica. Siena is resistant to alkalis and lime and is used in almost all varieties of paint. When mixed with oil, siena acquires a glaze effect. Such compositions are often used in finishing work on expensive wood.

- Red-red iron. Includes iron oxide and traces of quartz minerals. The color of the coloring matter is reddish brown. The pigment is extracted by finely grinding iron ore. The substance is not toxic in itself, but its dust contains toxins. Different brands of iron minium are used to add to alkyd primers and special-purpose paints and varnishes (for painting ships, anti-corrosion compounds). Also, the meerk found wide application in oil compositions for painting metal products located in the open air.The production cost of the element is low, so it is used in adhesive paints and enamels.

- Natural umber. The pigment includes manganese and iron oxides. Umbra color is brown with a touch of green or dark yellow. As a result of calcination, the umber acquires a red-brown color. The dye is characterized by high strength, good coloring properties. Adding umbra allows the oils to dry faster. Dye is used for plaster painting, metal and wood products.

- Chromium oxide. Pigment is produced as a result of complex chemical reactions. Color - from light green to dark green. The disadvantages of chromium oxide are explosiveness, toxicity and fire hazard. The advantages of the substance are its high resistance to light, great strength, resistance to acids and alkalis, even at high temperatures. Pigment can be added to pigments of any origin. Chromium oxide is used for critical coatings in chemical plants, pipe surfaces and equipment subjected to high thermal stress.

- Red lead Color - bright orange or orange red. It has a high weight and is a product of oxidation of lead lead at high temperature. Red lead is a very toxic material. The pigment is characterized by high resistance to alkalis, anti-corrosion properties and hiding power. Lead minium has a low resistance to acids.

- Mars is brown. Color - dark brown, light brown. The pigment is produced by calcining a mixture including manganese, iron oxide, aluminum oxide hydrate. Brown Mars is resistant to alkalis and light, as well as acceptable hiding power and glaze properties. The component is used with binders in aqueous and non-aqueous formulations. The coloring matter is used for painting metal and wooden products, as well as plastered surfaces.

- Emerald green. The dye is characterized by high glaze properties, resistant to light, humidity and gases.

- Cobalt blue. Color is bright blue. The substance is lightfast and tolerates the effects of precipitation, characterized by high desiccant and glaze qualities. Cobalt blue is characterized by increased oil absorption and low hiding power.

- Prussian blue is light-resistant, it is characterized by hiding power and color intensity.

Organic Dyes

Organics are extracted from insects and plants. Such dyes, unlike mineral dyes, are soluble in water, oils and alcohol. Organics are characterized by lower strength in comparison with mineral dyes. Since these pigments do not create a paint layer, but penetrate the surface structure, they are most often used for dyeing fabrics.

A common representative of organics is kraplak, extracted from the roots of madder or nettle. Another substance of plant origin is indigo, obtained from wajda. Modern industry also produces synthetic indigo. A light brown pigment is obtained from marine mollusks. The method of calcination from organic raw materials can be obtained black dyes.

to contents ↑Artificial pigments

Synthetic dyes are characterized by maximum resistance to moisture, precipitation, light and gases. They are characterized by the brightness of the shades. Thanks to such qualities, artificial pigments have long taken a leading place among all dyes.

Dyes of synthetic origin are divided into inorganic or mineral. Inorganic pigments are produced through complex chemical reactions.Synthetic inorganic pigments are characterized by a constant chemical structure, a bright and pure color.

The cost of manufacturing such components is quite expensive compared to natural coloring materials. Inorganic synthetics are used in the construction industry to create non-aqueous paints and varnishes.

Mineral synthetic dyes are created as a result of a combination of 2-3 components. According to the production method, such pigments are divided into precipitated from solutions of metals and salts or made by calcination.

to contents ↑Ultramarine

Belongs to the class of synthetic inorganic dyes. It contains sodium aluminosilicate and sulfur. Ultramarine is often used in the construction industry in paints, water and non-aqueous paints. Concrete, metal, wood, and also plastered surfaces are painted with such paints. In its pure form, ultramarine is used extremely rarely, and if this happens, the goal is usually to neutralize the yellow color of lime or chalk.

Ultramarine can be used as a glaze dye. The pigment is resistant to light and alkali. However, the addition of a coloring matter to lime solutions is undesirable, since the substance in this case loses color. Ultramarine is suitable for interaction with all types of binders in the implementation of internal and external finishing work.

to contents ↑Cinnabar

The dye is characterized by a bright red color, but there are also dark tones. Cinnabar can be used for the production of all types of paints used for painting concrete, brick, plastered and wooden surfaces. It is acceptable to use both for internal and external finishing work.

Pigments and properties of paints

An important element of the paint material is considered a binder. Its function is to connect the dye particles and fix them to the surface. Binders also affect color, since they all differ in the refractive indices of light rays.

A very important indicator for oil paint is the oil absorption of the dyes. Oil intensity is an indicator of the amount of oil that will be needed to make paint for a certain amount of pigment. The oil absorption index depends on the total surface area of the particles, and in addition, on the physicochemical characteristics of the oil used as a binder.

The next significant indicator that pigments affect is the drying speed of the paint. Some dyes, for example, cobalt and lead white, make the drying process more intense. Some pigments (carbon black, kraplak, etc.), on the contrary, slow down drying.

The pigment must correspond to a certain standard of the color background, which is determined by the structure of its particles, their capabilities for refraction, reflection and absorption of light rays.

Another requirement for dye is the required degree of dispersion. This quality is understood as the degree of refinement, which is achieved by mechanical crushing, settling, precipitation of a mixture of solutions (wet method) or by heating in special furnaces (dry method). The lower the dispersion, the more transparent the paintwork material, and vice versa.

The dispersion of the dye in some paints determines their hue. For example, finely ground zinc white gives a blue tint, and sienna increases the saturation of the tone. In oil compositions, increased dispersion leads to a decrease in ductility.

Dispersion also affects another indicator of pigment - hiding power. This characteristic shows the amount of dye needed per square meter of surface to be painted. It is understood that under the paint layer the lower surface or soil will not be visible.The spreading rate depends on the internal structure of crystals, which are characterized by different refractive indices of light rays.

Dyes with low dispersion are the basis of hull and coating coatings, and pigments with high dispersion are found in the compositions of glaze (more transparent) paints.

Intensity, as a characteristic of a pigment, is its ability to change the tonality of a paint layer when interacting with other pigments. The highest intensity is characteristic of organic-type dyes with a high degree of dispersion.

Tell me the paint and method of staining crushed stone

Take a look link