Varnish ML-92 is used to coat parts involved in electrical insulation. This tool has a low price and positive reviews, so it is widely used in industry.

- Purpose and properties of varnish

- Product Features

- Application of varnish

- Storage and packaging

- Security measures

Purpose and properties of varnish

Electrical insulating varnish ML-92 is produced in accordance with state standard GOST 15865-70. The composition of the product includes glyphthalic varnish mixed with melamine-formaldehyde resin K-421-2, organic solvents.

In its intended purpose, this paint material refers to the means on which electric voltage can act. It does not lose its properties under the influence of current, surface discharges, perfectly withstands the action of high temperatures. The heat resistance class allows it to be operated up to +130 degrees, the lower limit of the application range is minus 60 degrees.

- in temperate and tropical climates;

- inside buildings, structures;

- under the awnings;

- in rooms with penetration of street air.

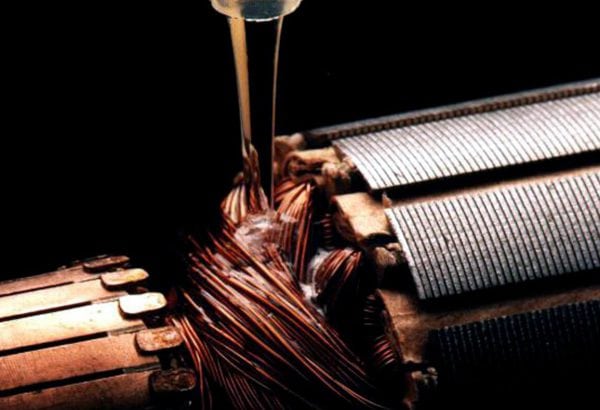

Most often, they cover the windings of electrical machines, apparatus and instruments, transformers, individual parts (including automobile parts) that require electrical insulation. ML-92 has a lot of advantages:

- good safety of products in aggressive environments - under the influence of acids, alkalis, salts, gases;

- oil resistance, strength, durability;

- thermoplasticity of impregnation.

Product Features

Technical characteristics of the product are regulated by the above state standard. Here are the main ones:

- structure and type of film - homogeneous, without impurities, smooth, without craters, glossy;

- the drying period of the film is 1 hour at +105 - 110 degrees in a thin layer, if the layer of material is thick, the time at the same temperature increases to 16 hours;

- material consumption per layer - 40 - 48 g / sq. m surface;

- the layer thickness of the funds is 20 to 30 microns;

- conditional viscosity measured by the device viscometer VZ-246 with a nozzle of 4 mm at a temperature of +20 degrees, - 25 - 50 s;

- fraction of dry (non-volatile) residue - 50 - 55%;

- thermoelasticity at a temperature of +150 degrees - 48;

- dielectric strength at +20 degrees - 70 MV / m, at +130 degrees - 40 MV / m, under the influence of water during the day at +20 degrees - 30 MV / m;

- the hardness of the device of the pendulum type at +20 degrees - 0.4 at. e .;

- the specific resistance of the coating at +20 degrees is 1 * 10 * 12 OM / m, at +130 degrees - 1 * 10 * 9 Ohm / m.

to contents ↑After drying at the place of application of the product, a brown film is formed, from a dark shade to a light one.

Application of varnish

Before applying the product, prepare the surface. To do this, they clean it from dirt, dust, remove stains of oil and other fat. The surface must be completely dry. Varnish should be well kneaded before use, if necessary it is diluted to obtain the desired viscosity. White spirit, toluene, xylene or a mixture thereof in a 3: 1 ratio can be used as solvents. Before applying the material, priming is optional.

The product is applied by dipping (relevant for small parts) or in bulk. It is necessary to carry out 1 - 2 layers of varnish depending on the needs. First, perform one layer, allow it to dry completely.

First, conventional drying is preferred at + 20 ... + 22 degrees for about 20 minutes, then hot drying is done for 1 hour at + 105 ... + 110 degrees.Next, you can perform the second layer of funds. If necessary, perform a thick layer and dry it for no more than 16 hours at +120 degrees.

to contents ↑Storage and packaging

Material can be stored for 12 months from the date of issue. For this period, the manufacturer guarantees full compliance with technical properties and parameters. So that the product does not deteriorate, it is stored in a tightly closed container (factory), protected from sunlight, away from sources of heat, moisture. Recommended storage temperature -40 ... + 40 degrees, as with most paints and varnishes. The product is packaged in industrial containers according to customer requirements.

to contents ↑Security measures

Before working with this paintwork material, protective equipment and clothing must be prepared. All work can only be done with gloves, a respirator, and tight clothing. The room should be well ventilated.

The varnish is flammable, you can’t work near sources of fire, sparks. In case of contact with skin and eyes, rinse immediately. The penetration of varnish vapor into the respiratory tract must not be allowed.