Parquet differs from any other wooden floor in that it needs to be regularly and properly looked after. Today, to protect the parquet board and increase its life, parquet varnish and various oils are used.

- The main factors to consider when choosing

- Types of Parquet Lacquers

- Priming paintwork material

- Primer Application Rules

- Water Soluble Varnishes

- Polyurethane varnish

- Application Rules

- Oil based alkyd varnishes

- Formaldehyde varnishes

The range of coatings for the processing of parquet in the building materials market is impressive. Therefore, the question of the correct selection of parquet varnish is quite relevant.

The main factors to consider when choosing

The leading factor that plays the main role in choosing the paintwork material is the functional tasks of the room and the predicted load on the flooring. That is, if the room does not have a large cross and only a few people are supposed to walk on the floor in slippers, then you can choose a varnish designed for minimal loads.

On the contrary, covering the floor of a kitchen or a corridor, it is best to choose a composition that can protect the tree not only from mechanical overloads, but also from chemical pollution.

If you want to cover the wooden floor in a restaurant or bar where maximum attendance is expected, then it is best to choose the composition with the highest strength indicator. For example, it can be varnishes with special oil impregnations and water-repellent components.

However, even after applying the most durable lacquer coating, floors with high traffic will still have to be regularly updated to restore the surface to its original appearance. Next, we will consider how to choose a varnish for parquet.

Types of Parquet Lacquers

All modern paint and varnish compositions for parquet are divided depending on the following parameters:

- chemical composition: urethane, anhydrous-based polyurethane, alkyd-urethane, formaldehyde, scuba and primer;

- according to aesthetic parameters: transparent, colorless or colored varnish, with which you can repaint in any color;

- according to the level of gloss: glossy, matte, semi-glossy, semi-gloss paintwork material;

- on technological characteristics: varnishes differ in viscosity level, application options and fluidity;

- resistance to mechanical stress, ultraviolet radiation, resistance to negative environmental factors, as well as the duration of operation.

Priming paintwork material

Primer for parquet board is applied directly under the first layer of other paints and varnishes. This coating can be applied to oak or other wood surface to improve adhesion to the film of varnish material.

Also, primers can be applied under the finish layers of varnish, helping to improve their quality.

The main goals of using a primer:

- to get an absolutely even color;

- to reduce the adhesive properties of the coating at the joints of wooden dies from the sides;

- in order to isolate natural oils on the surfaces of exotic woods;

- to prevent water from entering the surface of the dice.

Primer Application Rules

Before applying a primer to the surface of the parquet, make sure that it completely fits the finish layer. Otherwise, spots may appear on the floor that will be difficult to remove. Therefore, under a water-based paintwork material, it is necessary to apply a water-soluble primer.

When applying, it is important to remember that primer lacquer reduces the amount of money spent on the finish. This is made possible by reducing penetration.

It should be noted that the primer allows you to reduce the consumption of paint and varnish material for the finish coating. This is due to a decrease in penetration.

The primer material dries quickly enough, since it contains solvents that can quickly evaporate from the floor surface. In this case, the full drying time is on average from 20 minutes to 2-3 hours.

To obtain the most optimal effect, it is necessary to use a primer varnish and finish composition, which has a certificate of one manufacturer. This is because materials from different manufacturers have different degrees of purification from various impurities.

Therefore, if a domestic primer is applied under the finish varnish of imported production, the final result may turn out to be worse than usual.

Water Soluble Varnishes

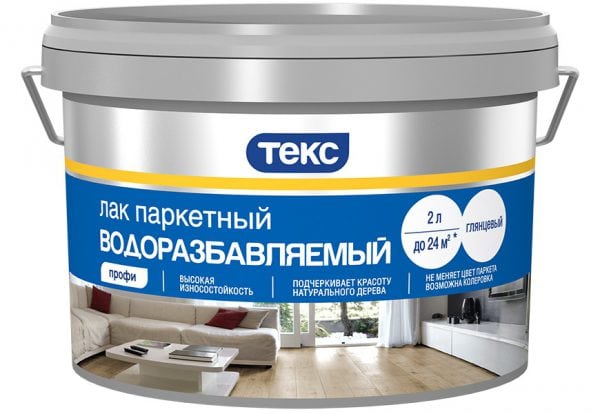

One of the best options for oak is a water-based tex parquet lacquer. It is considered very advantageous in terms of combination of price and quality. The composition of the water-soluble composition includes water, emulsifiers and small particles of solvent.

Since the main component here is water, such a varnish dries not like conventional formulations. First of all, water evaporates, and after it the solvent dries. Thanks to this, water-based varnish forms a strong and extremely hard film. In their composition, water-soluble paints and varnishes are divided into the following types:

- solvent free;

- solvent content up to 5%;

- solvent content from 5 to 15%.

Each of these types has certain adhesive properties. However, in any case, regardless of the concentration of the solvent, water-based varnish has good adhesion to the wooden coating.

The main positive qualities of varnishes based on:

- lack of an unpleasant smell, therefore, such material can be applied on a parquet even in the presence of people in the room;

- absolute fire safety, since such a composition does not ignite due to the water base.

In general, water-based varnish is excellent for covering parquet. However, when working with it, you need to remember that this composition can penetrate into the cracks between the dies. This can lead to various creaks in the floor. To partially eliminate this problem, it is possible to previously apply a water-based primer to the floor surface.

Among the shortcomings of scuba diving, one can also distinguish reduced wear resistance. However, if the standard composition is supplemented with a hardener or other nozzles, the service life of such a coating will increase significantly. In this case, to apply such a coating, it is necessary to maintain humidity at a level of not less than 50%.

However, in winter it will not be easy to achieve such indicators. In addition, water-based varnishes are quite demanding when choosing a means of application.

It is undesirable to apply water-soluble formulations with a brush, tampons, sponges or spatulas. Therefore, the only optimal option for coating the surface with waterborne varnishes is a roller.

to contents ↑Polyurethane varnish

Polyurethane paint and varnish was specially developed to cover the surfaces on which many people pass every day. One of the representatives of this class is parquet varnish PF 231, which is characterized by high strength and excellent adhesive characteristics with respect to wood.

Types of polyurethane varnishes:

- single component;

- two-component varnish for parquet;

Unicomponent formulations contain only polyurethane and solvents, while bicomponent formulations may contain acrylic, alkyd and other constituents. The most widespread among two-component materials was alkyd-polyurethane varnish. Both types of solution can contain all kinds of aromatic substances, which can give the paintwork material a more acceptable aroma than usual.

As a rule, polyurethane varnish dries much faster than water-soluble. Here the solvents immediately begin to dry, and subsequently the coating hardens due to chemical polyaddition.

The main positive qualities of polyurethane anhydrous compositions:

- lack of need for preliminary priming;

- resistance to any temperature and natural influences in the room, including the negative impact of UV rays;

- water resistance of the coating during operation;

- elasticity;

- high wear resistance;

- quick drying time.

Application Rules

When painting with polyurethane varnish on a parquet floor, the surface should be protected from harmful effects with moisture until it dries. Even with a low moisture content of wood up to 8%, air bubbles may appear on the wood flooring or even foaming of the paint layer may appear.

In general, when applied correctly, anhydrous polyurethane varnish is excellent for parquet in rooms where many people are on a daily basis. Moreover, it will not be difficult to take care of such a coating.

Oil based alkyd varnishes

The composition of this material includes alkyd resins obtained from natural components. Since such paints and varnishes include linseed and wood oils, they can penetrate deep into wood. In addition, white spirit may be contained in the complex composition of alkyd varnishes.

Positive features of alkyd compounds:

- contribute to the improvement of the natural aesthetic qualities of wood, regardless of whether you chose clear or dark lacquer;

- low adhesive characteristics, due to which the alkyd material does not flow into the cracks between the parquet boards;

- resistant to temperature extremes and mechanical overloads.

Negative qualities:

- sensitivity to high temperature during the drying period, which forces you to open windows and doors to reduce it;

- during application, carefully monitor the thickness of the layer. Therefore, if you are carried away and apply a lot of varnish in one layer, then the surface can become covered with waves;

- low wear resistance.

Formaldehyde varnishes

This varnish is the most wear-resistant, therefore, if you want to protect your parquet as much as possible from mechanical stress, then this option will be the most optimal.

The main component of this composition are formaldehyde resins.

Despite their toxicity, these components will not be harmful after drying, as they evaporate quickly and leave no residue.

Key benefits:

- excellent traction in relation to wood;

- resistance to sharp temperature drops in the room;

- the ability to apply with any tools;

- application without preliminary priming.

Disadvantages:

- the presence of a pronounced smell, which makes it work in a well-ventilated area with a respirator;

- excessively glue the sides of the parquet boards.

Thus, to the question which parquet varnish is better, there is no definite answer. For example, for rooms with a better use of formaldehyde or polyurethane varnish. At the same time, for an bedroom or a living room, it is quite enough to take an alkyd paintwork or scuba.

Hello! Situation: light lacquered floors are damaged mechanically. We want to make them dark, we don’t want to tear off the old paintwork (laborious, expensive, for a long time). If you cover what is dark varnish, will the result be terrible? thanks