Spray varnish is very popular among car coloring masters, as well as in the manufacture of furniture. It is convenient to use and better covers the surface than that applied with a brush. Aerosol varnish has a lot of other advantages, but it also has drawbacks that must be familiar with before use.

- The scope of the tool

- Aerosol spray can

- Advantages and disadvantages of spray cans

- Varieties of varnishes

- Polyurethane

- Acrylic

- Nitrocellulose

- Glossy or matte varnish - which is better

- Colored and transparent varnishes

- Features of the application of materials

- Proper storage

- Tips & Tricks

The scope of the tool

Varnishes in the form of aerosols belong to the group of paints and varnishes (LKM), have a variety of uses in the household. The most famous and purchased universal formulations that can be used in this way:

- like car paint for body repair;

- for wood coating, varnishing of various types of furniture;

- for applying a protective coating to works of art, accessories for the bathroom, kitchen;

- for varnishing toys;

- in the construction industry;

- in the electrical field.

Other varnishes are used narrowly, for example, they are bought only for cars or wood. Some acrylic products are designed solely to protect electrical components from damage. Nevertheless, many paintwork materials in cylinders are interchangeable, they can be sprayed on various types of substrates. Unites all aerosol varnishes one thing - the area for their application should be small. To cover the floor, you should purchase a regular paintwork in a bank.

to contents ↑Aerosol spray can

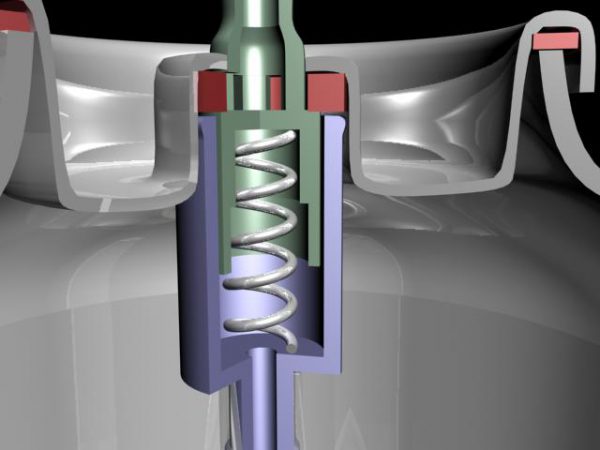

The concave bottom protects the cylinder from high pressure. Inside, there is paint (varnish) and inert gas, and a tube passes through which the paint comes up. It ends with a spray head with a valve, the latter does not allow the medium to exit before being pressed.

The varnish in aerosol form contains a sufficient amount of diluent (solvent), so it is sprayed with very small drops. But liquid varnish can be applied in several layers, which gives a better result.

to contents ↑Advantages and disadvantages of spray cans

The use of spray varnishes for cars, furniture or other items has several advantages:

- the readiness of the compositions for use - they do not need to buy additional equipment (rollers, brushes), they do not need to be bred and mixed;

- mobility, the ability to take with you or carry out repairs in any place convenient for this;

- saving money on the purchase of solvent, tools, low varnish consumption, reasonable price;

- quick drying of the composition - usually it takes several minutes for it to seize or even completely dry; this property determines the absence of streaks, stains on the treated surface;

- suitability for wood, plastic, metal, other materials, as well as for planes of various shapes (flat, curved);

- the ability to apply in hard to reach places;

- no need to have application experience - even beginners will cope;

- the presence of matte and glossy, color and colorless compositions.

All varnishes in aerosol form have good physical, chemical and operational characteristics.They are resistant to water, steam, elevated or low temperatures, dirt, detergents, aggressive substances. The varnish film can reflect the sun's rays, does not fade from the action of ultraviolet radiation (even in a dark color).

Many products perfectly protect products from rust and mold, are heat-resistant, and prevent short circuits (if used in electrical engineering). The temperature range of their operation can be -70 ... + 120 degrees.

There are almost no disadvantages for varnishes. Only indicate the need to comply with the instructions for the layer thickness. Otherwise, the quality of the coating will decrease, and the drying time will increase. Some cylinders may run out of gas too early, the sprayer may break, which will make the paintwork unsuitable for further use. Another disadvantage is the need to protect the surface before the composition dries, otherwise dust particles and other pollutants may stick to it.

to contents ↑Varieties of varnishes

In the store you can choose paintwork in aerosol packaging according to individual requirements. In the world, it is customary to label such paints as HS and MS (hard, soft):

- HS varnishes are applied in 2 coats. The first is light, the second is more durable, 40–50 microns thick. The fluidity of the varnish is small. Due to their low solvent content, coatings labeled with HS are considered environmentally friendly.

- MS varnishes require application in 2-3 layers. They have a fluid structure. Typically, manufacturers are advised to apply each coat 15 minutes after the previous one.

There is also a different classification of varnishes depending on their constituent substances.

to contents ↑Polyurethane

Polyurethane products are used for reliable protection of metal, wood, plastic from any damage, including mechanical ones. They contain polyurethane, as well as diisocyanates, polyesters. Therefore, resistance to chemicals at a high level. In cylinders such varnishes are usually sold in a single component form. Also on sale are two-component products in the form of a basic composition and hardener. The latter will have to be mixed before application.

to contents ↑Separately, it is necessary to describe polyurethane-alkyd varnish. When alkyds react with polyurethane, the agent gains increased strength. Its big minus is the presence of a sharp, unpleasant odor due to evaporation of the solvent.

Acrylic

Acrylic varnishes are considered the safest for humans. They are often called furniture, the main component of the composition is acrylic resins, after application of which the natural shade of wood is enhanced. Furniture, wooden structures after varnishing do not turn yellow, do not deteriorate from ultraviolet radiation.

The composition of these varnishes is water, and drying occurs precisely due to its evaporation. The coating is a film with excellent adhesion to various materials. In addition, it is not exposed to the harmful effects of mechanical factors. But such varnishes are afraid of water, and they cannot be used in rooms with high humidity.

to contents ↑Nitrocellulose

The composition of the coatings of this group is represented by resins, colloxylin, organic substances and solvents. Varnishes are suitable for rooms with any temperature and humidity, they are applied to all types of surfaces. In residential premises, funds should be used with caution - until completely dry, they are toxic to humans.

to contents ↑You can use nitrocellulose varnishes to create a beautiful coating for furniture and a car. If the composition contains chromium, the product additionally has a reflective effect.

Glossy or matte varnish - which is better

Gloss is better suited for black or dark surfaces, giving it an original shine. Also, paintwork materials provide a beautiful line transition, emphasize contrast and pattern. Glossy varnishes look perfect on furniture; therefore, they are popular in this type of production. Minus can be called the noticeability of even the smallest defects on the gloss.

Matte varnishes in the form of sprays look stylish on the finished product, while significantly simplifying the cleaning process - just wipe the surface slightly. It is recommended to use matte products when the natural appearance of objects is important. The strength of glossy and matte coatings is the same, it is affected only by the quality of the varnish, its brand and the components that make up it.

to contents ↑Colored and transparent varnishes

Transparent varnish is the most popular in car repair and furniture production. It does not need to be additionally tinted, it will not change the color of the main coating and will not hide the natural beauty of the tree. Transparent varnishes are indispensable for coating rims, headlights, as well as expensive varieties of wood - oak, beech, mahogany.

Colored varnishes are often used for cheaper types of wood. They help:

- enhance the brightness of the paint;

- protect wood;

- give the product a noble appearance.

Most often, shades are used for different types of wood, as well as white, beige and black. Light paintwork materials cover the parquet, laminate, furniture to improve the appearance, gloss. When buying a product, it is important to take into account the penetration depth and the degree of gloss (the surface will look darker from strong gloss).

Tinting varnishes for car bodies should have increased strength. Suitable for these purposes 2K glossy and a series of varnishes brand KUDO. There are specialized products in headlight spray sprays (for example, Lens Clear HB Body headlight spray varnish).

to contents ↑Of the colored matte varnishes, Auto Dip liquid rubber should be noted, providing incredibly rich, vibrant shades. To improve the aesthetic properties, glittering agents and reflective additives are used. But, as a rule, they are used for painting bicycles, motorcycles, ATVs, as well as helmets.

Features of the application of materials

Before starting work, it is important that the foundation is properly prepared. If varnish is applied to a new paint, the coating should be dry and even. Old enamel layers will have to be cleaned and degreased. As a result, dirt, dust, rust should not remain on the surface, otherwise after varnishing “shagreen leather” will turn out. Requirements for the premises for work: closed, well-lit, ventilated, with a temperature of 20 degrees.

The procedure is as follows:

- shake the container with the material well;

- apply a developing (semi-dry) layer of varnish, spraying it from a distance of 35–40 cm, you cannot stay in one place — otherwise there will be leaks;

- allow the product to dry (the time is indicated in the instructions for the specific tool, usually 10 minutes);

- make another 2-3 layers of varnishing;

- dry completely (naturally or with infrared heaters).

If the varnish remains, it can be used later. It is only necessary to clean the sprayer. To do this, turn the bottle over and spray to a complete stop.

to contents ↑Proper storage

If storage conditions are not followed, the varnish will quickly deteriorate. Usually, the shelf life of a quality product is at least 2 years, but violation of the conditions reduces this time. You need to carefully read the label, which indicates the storage parameters of paintwork materials.

It is especially important to clarify the ambient temperature. Prolonged freezing renders most varnishes unusable. The product becomes cloudy, and application to furniture or the car body will lead to unpleasant consequences. Prolonged storage at high temperature causes the hardeners to thicken, and after 1-1.5 months the cylinder will have to be thrown away. The recommended temperature range must be strictly observed, then the varnish will remain fresh for a long time.

to contents ↑Tips & Tricks

Popular brands of varnishes are as follows:

- Mobihel 1K. Used for painting cars. It forms a dense layer without sagging. Transparent, applied over the paint as a topcoat. Dries completely in 60–90 minutes.

- Brulex Acrylic spray varnish, creates a decorative glossy coating on surfaces made of wood, metal and plastic.Dries in the air, does not turn yellow.

- Holex. Acrylic spray for painting the body, dries quickly (less than an hour). Very persistent, does not get cloudy.

Before applying it is better to practice in an inconspicuous place, especially if the work is done for the first time. Do not forget to shake the bottle with varnish before use, so that the composition is uniform. A respirator and protective gloves should be used in the work area, as many varnishes contain toxic solvents. These tips will help to varnish with an excellent result and is safe for health.