ХВ-784 varnish is a paint and varnish material used to protect wood, concrete, reinforced concrete and metal surfaces from the harmful effects of moisture, alcohol, alkaline and salt solutions. It is used in carpentry for varnishing wood products, plywood, including veneer sheets. Suitable for work at home - varnish XB-784 open the railing, platbands, doors, baseboards. The material is not used for floor treatment.

- Specifications

- Application area

- Surface and material preparation

- Application

- Security measures

- Storage and transportation

Specifications

LKM XB-784 is made on the basis of chlorine-containing polymers, the majority of which is perchlorovinyl resin. It is obtained by chlorination of a polyvinyl chloride resin to a chlorine content of 62-65%. Perchlorovinyl varnish forms a film that quickly dry in air, which is characterized by increased hardness, water resistance and wear resistance.

The composition of the varnish XB-784 also includes:

- plasticizers;

- dyes;

- organic solvents.

Among the characteristics of the XB-784 can be noted:

- consumption per 1 square. m working surface is 210-220 g;

- layer thickness - 18-20 microns;

- number of layers - 2 or 3;

- the proportion of non-volatiles is from 15 to 17% by weight.

XB-784 is produced in Russia according to GOST 7313-35. The main purpose is the primer and coating of concrete building structures.

The varnish has a certificate of conformity - this is a certificate of state registration issued by the Office of the Federal Service for Rospotrebnadzor. There is also a sanitary-epidemiological conclusion of the Center for Sanitary and Epidemiological Surveillance.

Available in 0.5 liter glass bottles, 1 liter galvanized cans, 20 liter euro buckets, 200 liter steel barrels under the name “Bleached Oak”, “Mahogany” or in other color variations. By agreement with the customer, the packaging can be of any volume.

to contents ↑Application area

LKM is intended for the protection of concrete, reinforced concrete, brick, asbestos cement and other mineral surfaces. Black and red-brown varnish is used as part of a complex coating, which is selected individually for each type of aggressive medium in accordance with the normative documentation for painting. XB-784 is used in multilayer compositions, which are applied both to pre-primed and to unprepared surfaces.

A distinctive feature of perchlorovinyl coatings is their high resistance to mechanical stress. In addition, they are perfectly opposed to atmospheric phenomena. They can be operated from -30 to +40 ° С. Perchlorovinyl coatings:

- Resistant to UV;

- without loss of characteristics withstand prolonged exposure to water;

- possess high wear resistance.

Important! Surfaces coated with perchlorovinyl can be washed using synthetic detergents.

XB-784 is used together with XB-785 enamel. At the same time, the protection of such a coating from acids, alkalis, salts, harmful aggressive gases, such as CO2 and SO2, will be guaranteed. Operating temperature +60 ° C.

Acids that may impair the integrity of the coating:

- sulfuric;

- saline;

- phosphoric.

Another purpose of the varnish XB-784 is tinting and wood protection. If you want to get a lighter shade, the product is combined with a simple colorless varnish.

Among the obvious advantages of using XB-784 for wood processing, the following can be distinguished:

- resistance to water, weak solutions of acids, salts, alkalis;

- convenience in work - the varnish dries quickly, so the next coat can be applied after a short time;

- beauty of processed products - tinting emphasizes the natural color of wood.

The colors used can be of the widest range, selected according to the customer. In addition to the common black and dark brown colors, gray, yellow, ivory and others are used. On special request use white color.

to contents ↑Surface and material preparation

The varnish must be thoroughly mixed until a homogeneous mass and the sediment disappears completely, then wait a bit until all the bubbles disappear. The viscosity of the composition is very important:

- when spraying with a spray gun - from 18 to 25 seconds;

- when applied by roller or brush - 25-30 seconds.

On a note. Consumers often ask themselves how to dilute varnish if it is too thick. It can be diluted with toluene or solvents R-4, R-5 (indicated in the instructions for paintwork), as well as xylene brand "Novbytkhim" according to GOST 7827. The viscosity of the varnish is determined using a VZ-246 viscometer, which has a nozzle with a diameter of 4 mm.

The order of surface preparation depends on the material:

- wood - remove old paintwork manually or using solvents, grind it with a grinder or emery cloth, pay special attention to efflorescence and oil stains (they need to be completely removed), remove dust from the surface and prime with AK-069 or AK-070 compounds;

- concrete and reinforced concrete - remove dust and oil stains, close holes and cracks, primer with the same compounds;

- metal - remove the old finish, carry out surface cleaning and anti-corrosion treatment, apply a primer.

to contents ↑Important! To protect any type of surface, one coat of AK-069 or AK-070 primer is sufficient. Instead of such processing, you can directly apply XB-784, and after it has dried, apply XB-785 enamel.

Application

Varnish can be applied in various ways:

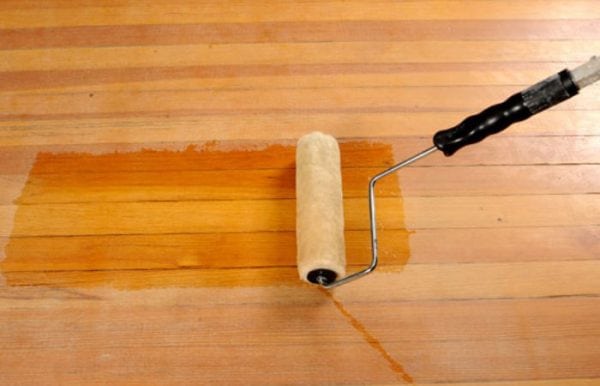

- Roller - if a two-layer coating is expected, the first layer is applied vertically, avoiding sagging. The second, after complete drying of the first - horizontally in stripes. In both cases, the overlap of adjacent layers is minimal.

- Swab - convenient for processing small surfaces or products. Dip the swab in the varnish and lightly apply it on the product. Try to avoid drips. After the first coat has completely dried, go over the product or surface again, but use less varnish.

- A brush is not the best way to apply varnish, or you need to purchase a very soft natural brush that will not leave streaks and hairs.

- Using a spray gun is the optimal method on large surface areas. It is important to choose the right viscosity, otherwise the nozzle will clog quickly. If there are welding spots or technological seams, then they are stained with a layer in the form of a “strip” with a brush.

to contents ↑Important! Due to their high absorbency, plastered, sandy or cement-sandy surfaces are varnished 2 or 3 times.

Security measures

The varnish is flammable, so you need to work in a well-ventilated area, in a respirator and gloves. If it comes into contact with the skin, the product must be removed with a solvent and then wash your hands with warm water and soap.

Tools are cleaned of residual varnish with xylene or acetone. Rags are disposed of to avoid accidental fire.

Storage and transportation

XB-784 is stored and transported in a tightly closed jar. Recommended storage temperature is from -20 to +25 ° C. In this case, it is necessary to completely exclude direct sunlight on a container with varnish.

XB-784 can be considered universal paintwork, which is suitable for protecting surfaces of any type.Among the advantages - giving wooden products and coatings made of natural wood a sophisticated appearance along with high-quality protection from external influences and moisture.

I dare to note that all products based on “Perchlorovinyl Varnish” cannot be diluted with acetone and solvents for nitro-paints. Only solvent R-4.

At work, the mechanic ruined 100 kg of such enamel by pouring a bucket of acetone into the barrel for dilution. Enamel has turned into a jelly-like structure. which is not diluted with any more solvent. The reaction is slow but true. I diluted the enamel of this type with diluent R-647, from the spray gun instead of colorful dust, a vermicelli flew - long strips of enamel dried under air pressure.

Very true noticed! Thank God, I did not dilute the varnish, but tried to clean the brush with the 647th solvent. I had to throw out the brush.

The same garbage.))) Only I saved the brush. Washed with a universal solvent No. 1. (Although I will notice the instructions say that solvent 647. can be used.)