Polyurethane foam is widely used in modern construction. Thanks to this material, almost any cavity in buildings is sealed. Polyurethane foam quickly seizes and protects the main material from external influences. At the same time, the foam itself has one vulnerability - ultraviolet rays are harmful to it. Therefore, puttying is used to protect the surface treated with foam. About what to putty with mounting foam, we will discuss this article.

- Ways to protect the foam

- Workflow Features

- The choice of composition and tool

- Foundation preparation

- Putty application

Ways to protect the foam

There are many options for protecting the foam coating:

- putty;

- finishing plaster;

- cement-sand mortar with the addition of white grout;

- polyurethane sealant;

- acrylic paints and varnishes;

- liquid plastic;

- putty.

So, based on the foregoing, the answer to the question of whether it is possible to put putty on the mounting foam is obvious and positive.

to contents ↑Advice! Before applying protective material to the mounting foam, it is recommended to lay it with pre-compressed sealing tape (abbreviated as PSUL). This tape is specifically designed to fill in bumps in new designs. For older structures, it is preferable to use a diffuse membrane type waterproofing tape.

Workflow Features

Puttying the mounting foam can be divided into several important stages, where the direct surface treatment takes only part of the time.

The choice of composition and tool

Before starting work, you need to prepare the necessary set of tools, which includes a knife, a container for the solution, two spatulas (wide and narrow) and work gloves. As for spatulas, with a narrow tool, the solution is selected from the tank and superimposed on a wide one, which is used to process the surface. Also, a narrow spatula is used to seal corners and hard to reach places.

In addition, it is necessary to purchase a putty. When choosing it, the following circumstances should be taken into account:

- Location of the processed surfaces. To work inside the building, some compositions are needed, while to work with the facade or wet rooms, others.

- Layer thickness and slit width. If the surface defects are too deep, it is probably best to plaster such cracks first. The fact is that the putty is intended to conceal relatively small defects and is applied with a thin layer, but with the help of plaster, you can close the recesses with a depth of up to 15 centimeters.

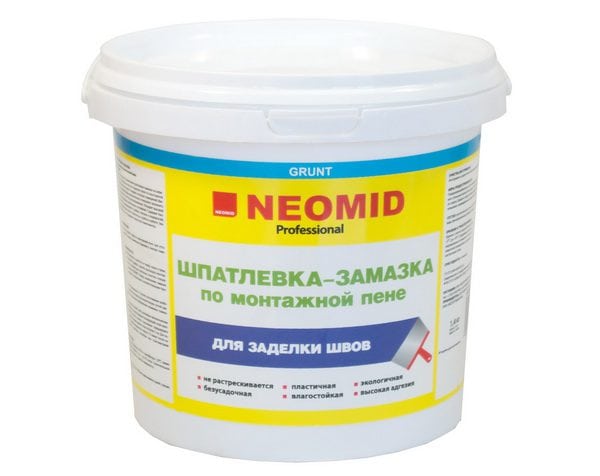

As an example of reliable compositions for dry rooms, gypsum plaster “Rotband” and putty “Fugenfüller” can be given. At the same time, the choice is far from limited to these mixtures. You only need to know the conditions in which the coating will be operated, and select the composition with them in mind. For example, mixtures based on cement or polymers are suitable for facades, and adhesive putties for tiles and thermal insulation boards.

The amount of the required mixture is determined depending on the area of the room and the consumption per square meter of the millimeter layer. The consumption of material will be described in more detail below.

Also can not do without a primer. The primer further protects the putty and provides better adhesion to the coating with the finishing materials.We can recommend the use of acrylic primer as having the largest list of positive characteristics.

If we are talking about finishing slopes, then the joints of window frames and plaster will require an additional level of protection, since it is in these places that cracking usually appears. A protective sealant can be used as a protective agent. The price of this tool is not too high, but the benefits are very tangible. The sealant is used simply: after applying the main composition (plaster, putty) to the surface, the finishing material is partially removed (3-4 millimeters from the edge). The sealant is poured into this cavity.

to contents ↑Foundation preparation

This stage is especially responsible, since the final quality of the putty depends on the thoroughness of the preparation of the foundation.

Preparatory activities are as follows:

- Using a knife, remove all protruding pieces of foam. As a result, the surface should become smooth, without any obvious defects and indentations.

- If the coating is unreliable somewhere, it is better to completely remove it, replacing it with cement mortar.

- We clean the surface of dirt and dust. A vacuum cleaner can be used for this operation.

- Primed the surface.

Putty application

The work is carried out in the following sequence:

- Knead the solution. The proportions of the components are indicated on the packaging. It is recommended that a very prudent approach to determining the total volume of the batch. If there is too much solution and it freezes, it cannot be reanimated with water, which means that the unused mass will simply have to be thrown away. The solution should be enough for about 30 minutes of work.

- We apply the starting layer of putty on the foam. If defects on the surface are noticeable after the first coat, an additional coat will have to be applied. The layer thickness depends on the type of putty (for example, for acrylic mixtures, the maximum layer thickness is 3 millimeters).

- When the starting layer is dry, it is recommended to grind and primer.

- Finishing putty is applied on a dry surface. The dried layer is again ground (fine-grained sandpaper) and primed. Now the surface can be wallpapered or painted.

So, in the putty on the foam there is nothing special that would distinguish this process from processing other types of surfaces. For a high-quality result, you only need strict adherence to the technological process in terms of surface preparation and putty application.