Novice builders often ask the question of whether plasterboard should be putty for laying tiles. Of course, the application of a putty layer strengthens the structure, improves adhesion (in this connection, the tile will hold firmly on drywall), reduces the consumption of glue. The features of the choice of materials, surface preparation and putty will be discussed in this article.

- Material Guidelines

- Workspace preparation

- Padding

- Features of structural strengthening

- Putty joints

- Joint reinforcement

- Fiberglass mesh

Material Guidelines

There are a number of rules that you must follow when choosing materials:

- To align the walls with plasterboard plates and further laying the tiles you will need a strong frame, securely mounted on the wall. As a framework, metal profiles are used. This design does not shrink, is not subject to deformation and swelling under the influence of humidity.

- Drywall must be wall-mounted and designed for use in high humidity conditions.

- Tiles should be selected to the minimum possible thickness. This is important because thick tiles make the structure heavier, making it less reliable. In addition, it should be borne in mind that the tile will adhere to the paper base, which is weakly connected with plaster.

- Another task is the right choice of glue. Conventional adhesives are made on the basis of cement. To prepare a working mixture of such adhesives, water is needed. Such adhesives can not be used when working with paper material, which in essence is drywall. You will need a glue on a synthetic basis, designed to fix the tiles. Adhesives such as Ceresit, Polimin, Vetonit Optima and other formulations of the same type can be recommended.

Workspace preparation

Before you putty the surface, you must prepare it. First you need to make sure that the screws do not protrude above the surface. If protruding self-tapping screws are detected, gently twist them deeper, but not too deep. Self-tapping screws should be located at the same level with the surface of the drywall. If there are too deeply recessed self-tapping screws, we replace them with longer ones.

to contents ↑Padding

The next step is the priming of drywall. Thanks to the primer, the surface will adhere better to the putty. You can do without a primer, but in this case it is possible to peel the putty along with the tile. The primer is applied with a wide brush or roller.

Note! On the packaging, the manufacturer provides instructions for using the primer.

A good primer should have the following set of qualities:

- The composition must penetrate deeply into the material.

- Good adhesion, which is the key to the longevity of the repair.

- Lack of toxic substances.

- Dust binding ability.

- Fast drying.

- Thermal resistant.

- The ability to withstand the effects of moisture.

- The presence of an antiseptic drug that prevents the development of mold and fungus.

Features of structural strengthening

The strengthening process includes a number of operations, which will be described below.

Putty joints

Joints must be putty separately. Thus, integrity and strength are transferred to the structure. When installing drywall panels, there are many joints - they are the weakest parts of the structure. It is at the joints that cracks most often form after laying the tiles. To prevent this, the seams must be thoroughly putty.

Putties are classified by purpose as follows:

- Starting compounds (leveling, basic), which are designed to conceal the largest surface defects.

- Finishing putty, used for the final finishing of the coating to perfect condition.

- Universal compounds that can be used to create both base and topcoats.

For puttying the drywall joints, putties are suitable, which do not give strong shrinkage when dried. To the greatest extent suitable for this purpose are polymer and gypsum mixtures. Unlike polymers, gypsum putties are not suitable for facade parts of a building and damp rooms. Otherwise, gypsum is an excellent material, which in most respects is not inferior to polymers. But cement for puttying joints should not be used, since this material is prone to shrinkage.

to contents ↑Joint reinforcement

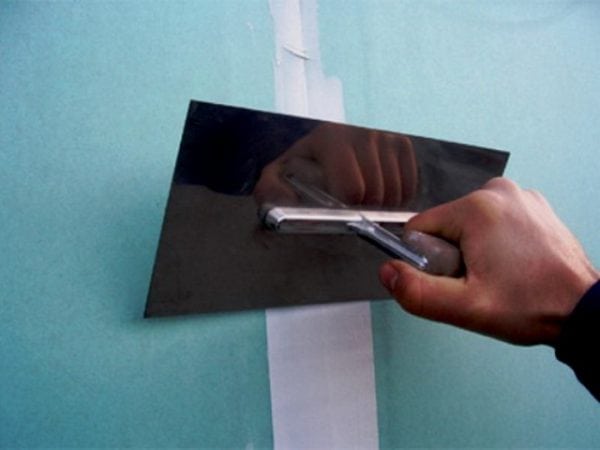

To achieve a more reliable connection of drywall sheets, even before puttying, the joints are laid with a special reinforcing tape. The best option for reinforcement is a ribbon-sickle made of synthetic material. This tape has another name - construction bandage.

When installing drywall panels between them, an approximately 5 mm gap is provided, in which the reinforcing tape-sickle is laid. The tape is about 5 centimeters thick. On one side, the serpentine has a sticky surface for gluing. The tape is placed so that it is glued to both panels throughout the joint. Next, putty is applied over the tape. Moreover, the tape does not prevent the penetration of the solution throughout the seam, since it has a cellular structure.

to contents ↑There is an alternative way to seal the joint with a syrup, but for its implementation it will take more time. However, the result is worth it, since the seam will be very durable. In this case, not a tape is put in the beginning, but a putty, which is then sanded with sandpaper. After this, a tape is laid, which is covered with a finishing composition.

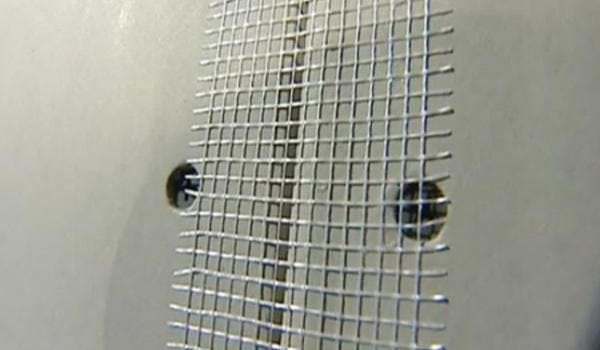

Fiberglass mesh

In recent years, fiberglass mesh has become widespread. The use of this material allows you to make the drywall design more rigid. In addition, the fiberglass mesh dampens the loads arising from temperature extremes.

The mesh is glued to separate areas near the door and window openings. In some cases, the grid is pasted over not only individual fragments, but completely the entire surface of the wall. After drying, the fiberglass becomes one with drywall, which gives the structure additional strength.

A mesh is made from a special type of fiberglass impregnated with an anti-alkaline composition. The internal structure of the product is interwoven glass filaments, which allows for high tensile and tensile strength. It is also worth noting the environmental safety of fiberglass and its fire safety.

Putty layer gives the surface additional quality characteristics, without which the design will not be sufficiently reliable. Thus, it is possible and necessary to putty plasterboard sheets under the tile.