Wall and floor decoration in the bathroom, bathroom, the formation of a working apron in the kitchen is mainly made of ceramic tiles. However, over time, the seams are abraded, clogged with dirt, and in the bathroom with constant contact with water, they can even become covered with mold spots. As a result, the whole kind of finish spoils. In order to protect the grout from wear, it is necessary to timely impregnate the tile joints with a special solution.

- Joint Putty Technology

- Epoxy Blends

- Polymer Compounds

- Cement putty

- Protective solution treatment

- Water repellent application

- Joint Seal Update

- Pencil painting

- Update

Joint Putty Technology

When choosing a ceramic tile finish, most often they discuss the characteristics of the tile itself: its design, laying technology and other points. The implementation of inter-tile seams is remembered much less often, and it depends on the quality of the grout how the entire surface will look like.

Of the variety of related finishing materials, the following types of grouts are distinguished.

Epoxy Blends

Resistant to chemical effects, temperature fluctuations, mold and mildew, it is easy to remove pollution from them. Due to its resistance to aggressive external factors, such a grout has been widely used in the treatment of rooms in which the humidity index is increased (for example, in a bathroom or shower).

However, only professionals in their field can work with epoxy compounds, since the consistency of the solution is quite viscous and requires great accuracy.

to contents ↑Polymer Compounds

They have significant advantages:

- plastic consistency;

- low shrinkage of joints;

- independence of speed and quality of hardening from temperature and humidity;

- frost resistance;

- ease of cleaning the tile surface from excess mortar;

- hydrophilic surface.

However, if you compare this composition with epoxy, it is significantly inferior in strength. To increase the strength of the solution, liquid polymers are additionally added.

to contents ↑Cement putty

This is the most common type. It owes its popularity to the reasonable price and simplicity of the application technology.

To make a grout, it is enough to fill the dry mixture with the required amount of water in accordance with the instructions indicated on the package. After drying the joints, you can remove the white coating formed on the tile with a regular sponge moistened with water.

Such joints are susceptible to contamination, and under the influence of moisture can darken or crumble, therefore, to preserve the appearance of the coating, they must be impregnated with a special solution with a water-repellent effect. Some masters add a primer to give the cement composition water-repellent properties when mixing the solution.

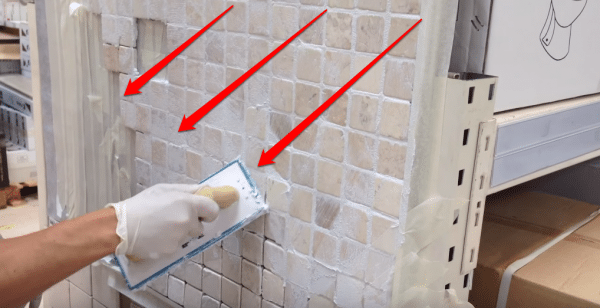

Grout is applied using a rubber spatula, pressing the solution into the gap between the tiles, or a special bag, which in its principle of operation is similar to a pastry bag.

to contents ↑Trowel bag is most often used when working with polymer or epoxy compounds.

Protective solution treatment

To create a coating on the tile joints that is resistant to water and cleaning agents, the occurrence of darkening, pollution and fungal formations, it is necessary to additionally impregnate the joints with special compounds with hydrophobic properties. Impregnation for joints has the following qualities:

- provides a hydrophobic coating (relevant when processing tiles in the bathroom);

- prevents surface contamination;

- has an antifungal effect.

For such processing are most often used:

- water repellents, which due to their liquid consistency are easily applied to the seams with a thin brush;

- polymer varnish that can penetrate deep into the grout (up to the base);

- sealants based on silicones or acrylic, which are used mainly in the most vulnerable places: in the corners of the bathroom or at the joints of the bath (shower) and tiles.

Now on sale are protective coatings that do not create a "glass" layer and do not affect the vapor permeability of the treated surface. Bicomponent compositions are also widely used, which, when dried, have high strength, durability and tightness. When grouting joints with such solutions, the need for additional impregnation disappears.

to contents ↑Water repellent application

It is recommended to impregnate no earlier than 7 days after grouting so that the surface is completely dry. In rare cases, the impregnation can change the color of the grout, therefore, in order to avoid unpleasant surprises, it is better to conduct a trial treatment in a hidden area.

The temperature treatment recommended by the manufacturer is indicated on the packaging. However, there are general requirements: processing must be carried out at a temperature not lower than + 5 ° C and not higher than + 30 ° C and relative humidity not less than 80%. Therefore, when working with such solutions in rooms with high humidity (bath, bath, pool, shower), it is necessary to clarify the indicators with a hygrometer.

Protective impregnation with water repellents is done with a thin brush gently along the seam. If the solution gets on the tile, its surface may become cloudy. To avoid damage to the finish, it is recommended to glue the edges of the tiles with masking tape. Water repellents can penetrate into the grout, so you need to apply a second layer to provide a water-repellent coating.

to contents ↑Joint Seal Update

If the seams become dirty over time, then there are two ways to give a fresh look to the lined surface in the bathroom.

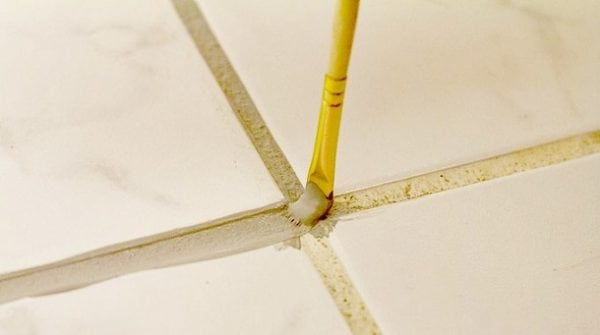

Pencil painting

It is necessary to wash the seams with cleaning products, wait for them to dry and cover with a water repellent. A special pencil for grouting, made in the form of a marker, is sold in construction stores. The tool will perfectly cope with the cleaning of the joints of the tiles in the bathroom, since the solution included in its composition is able to destroy mold and prevent the formation of fungus.

Many housewives, when cleaning tile joints, use not only industrial cleaners, but also resort to old folk methods:

- To eliminate the fungus or mold that appeared on the joints in the bathroom, you need to conduct surface treatment with a solution of vinegar, ammonia and a water softener.

- Another way to combat moldy stains is alcohol. It must be applied to the joints with a small brush (an old toothbrush will do), soak for a while and wipe away the dirt.

- An aqueous solution of antifungal drugs (Nystatin) will also help to remove mold in the bathroom. To prepare the solution, it is enough to dissolve the tablet in a small amount of water.

- To whiten light joints, you can use ordinary household bleach with chlorine.Simply fill the seams with a solution and brush it.

- In case of severe contamination, the joints can be sprinkled with baking soda and poured with vinegar. The foam formed as a result of the chemical reaction will simply push out the dirt and it can easily be washed off with water.

to contents ↑Work with cleaning products (even those that are prepared on their own) must be carried out in compliance with safety precautions: in rubber gloves, and if necessary, in a respirator.

Update

You can update the grout like this. Remove the old coating with an ordinary construction knife or a special “binder”. The choice of a tool is an individual matter, the main thing is that the tool does not leave scratches and other damages on the tile surface.

If the old layer is strongly hardened and cannot be removed by the usual mechanical action, the grout can be treated with special softening compounds. It should be noted right away that it will not be possible to remove the epoxy putty yourself - this is a matter for professionals. Then:

- after cleaning the seams, process the ends of the tiles and joints with a primer;

- perform fresh grout;

- when the grout is dry, you can begin to apply a hydrophobic solution.

In order for the lined surface to serve as long as possible and look like new, it is recommended to renew the grout once every 3-5 years.

Many people mistakenly believe that light grout is subject to more pollution than coating dark shades. In fact, they are polluted in exactly the same way, but pollution stand out more against a light background. It is possible to preserve the aesthetic appearance of a ceramic tile coating only by observing the technologies of its laying and grouting and the proper care.