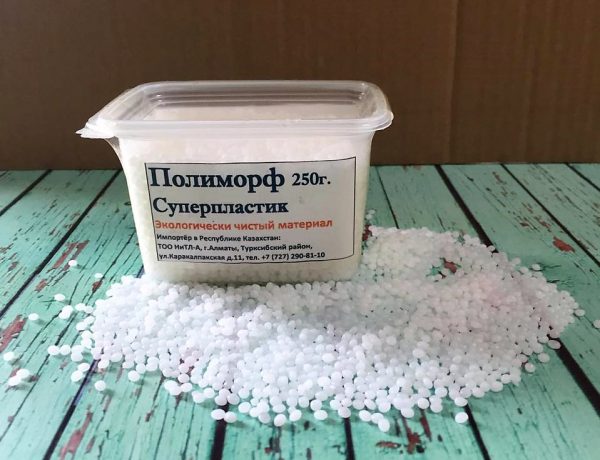

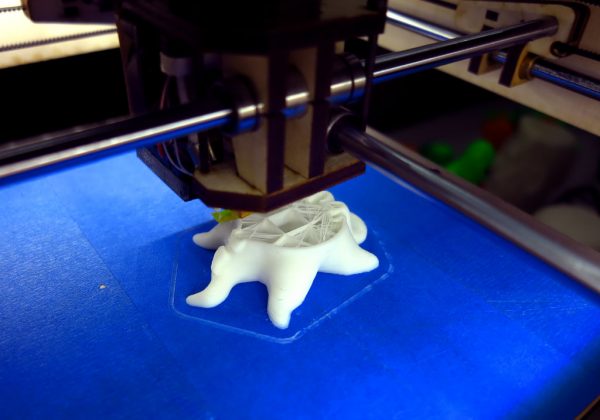

Polymorph is a real find for craftsmen with golden hands. Modern thermoplastic was originally intended for 3D printing, but found widespread use in everyday life. The main feature is that it can be used at home, without the acquisition of expensive equipment.

- What is thermoplastic?

- Key Features and Benefits

- Biodegradability

- Scope of application

- Terms of use of thermoplastics

- Precautions when working with polymorphus

The possibilities of thermoplastics are almost endless. It is actively used in the industrial sector, and indispensable at home. If desired, it allows you to form various devices that are useful and practical in everyday life.

What is thermoplastic?

This is a polymer from the caprolactone class. It has good ductility, and a high degree of viscosity helps to create arbitrary shapes. Thermoplastic is actively used in the manufacture of:

- pipes;

- plastic sheets;

- rods and other products.

The presence of polymer resins makes thermoplastics a homogenized liquid when heated to +65 degrees Celsius. As it cools, the material begins to harden, while maintaining a given shape.

The disadvantage of polymorph is its sensitivity to low temperatures. The structure becomes glassy and brittle. Rough handling and strong impacts can lead to the destruction of the crystal lattice.

If desired, thermoplastics can be melted again, given the desired shape and cooled. Repeated use has made this material extremely popular. This is facilitated by the affordable market value of the polymorph.

When purchasing thermoplastics, it is important not to make a mistake in choosing. There are various types of this material. They differ from each other in physical, chemical, operational properties. Thermoset plastic, for example, breaks down when heated. It is unsuitable for creating improvised tools.

to contents ↑Key Features and Benefits

Polymorph is convenient, practical, reliable and affordable. Its melting point varies between + 60 ... +65 degrees Celsius, depending on the composition and manufacturer. Outstanding quality is the high tensile strength - 580 kg / sq. cm.

Among the other advantages of polymorph it is worth highlighting:

- non-toxicity;

- the possibility of multiple modeling without compromising consumer qualities;

- self-curing under normal environmental conditions;

- practicality (does not stick to hands, does not leave greasy marks and dirt).

Finished thermoplastic products can be painted with acrylic / powder paints, making them more attractive. Polymorph can easily be machined: cut, drilled.

The listed features show how practical and useful this material is. Next, we will talk about the possibilities of its application, but for now it’s worth highlighting another important factor: safety for the environment.

Biodegradability

With proper use, thermoplastics are not harmful to health. It is a biologically safe material: decomposes in the soil upon disposal. Polymorph disintegrates into harmless components that do not harm the environment. Due to this important property, this material has found active application in the following industries:

- medicine;

- modeling complex three-dimensional objects;

- making clothes and shoes.

When considering the disposal of thermoplastics, its composition must be taken into account. In industry, upon receipt, it is often added additional components that enhance the properties of the material. It may even be starch. A change in composition entails an increase or decrease in decomposition time in the soil.

When buying a polymorph, it is recommended to consider the following parameters:

- chemical composition;

- degree of moisture absorption;

- requirements for humidity and ambient temperature.

Scope of application

Thermoplastic is convenient in that it allows you to get the product of the desired shape and high strength in the shortest possible time. This important property has greatly expanded its scope. The material is suitable for the manufacture of single products. It can be:

- handles for cutlery, knives and tools;

- useful devices for people with disabilities;

- casts and molds for casting.

Resistance to atmospheric loads makes thermoplastic indispensable in the manufacture of vacuum molds. It is applicable to obtain parts of various mechanisms. Suitable even for devices necessary in everyday life:

- lamb for the mixer;

- case for glasses;

- nozzle for a cap on a bottle for easy opening;

- orthopedic tire;

- protective overlay for workwear;

- bowl for the animal.

Terms of use of thermoplastics

For convenience, we will consider the use of polymorph at home, without special laboratory equipment. You can give the desired shape to the material with your hands, without fear of burns. However, it is recommended to make sure that it is heated at temperatures up to +65 degrees Celsius, not higher.

Useful life hack: when thermoplastic is in a liquid state, you can add paint to it, which will change the color of the material from white to any one of your choice. On sale you can find additives with sparkles, which allows you to make beautiful crafts for children. You can also use other means:

- watercolor;

- acrylic;

- gouache.

If desired, a marker or colored crayons can be used. Polymorph is compatible even with food colors. For example, if you want to give it a pleasant yellow color, then add turmeric to the composition.

The procedure for using thermoplastics is as follows:

- Heat a small amount of water in a pan or pour boiling water from a kettle into it.

- Pour polyform granules (as required).

- Wait until the thermoplastic changes its structure from matte to transparent, colorless.

- Get the formed lump from the bottom (when gluing it will drown), using an ordinary fork.

- Soften by picking up (thanks to the low heat dissipation, it almost immediately cools to the permissible norm and does not burn the palms).

- Give the material the desired shape.

- Leave to cool on a table or place in a container of cold water, which will speed up curing.

If you want to make a handle for a tool, you need to place it in a heated thermoplastic and stick the product on the outside. Due to its high strength, the polymorph will perfectly retain its desired shape.

to contents ↑Precautions when working with polymorphus

To determine the exact temperature of the water, it is recommended to use a thermometer with a scale of up to 100 degrees. You should not melt the polymorph in boiling water, as it will turn into a sticky and sticky mass, unsuitable for modeling.

If you want to remove water from a preheated mass, you can do it by hand. Just wring out the thermoplastic and it will be ready to use. For greater convenience, you can use ordinary tongs when you get the mass from the bottom. The molten polymorph does not adhere to the walls of the dishes.