In everyday life or during repair work, a need often arises for cleaning products from old paint, other coatings, and rust. For such purposes, sandblasting is ideal - grinding, polishing products using an air-abrasive mixture. The necessary equipment for cleaning surfaces - a sandblasting chamber - can be purchased ready-made or made by hand.

- Types of sandblasting chambers

- The device and principle of operation of the camera for sandblasting

- Buy or make a home-made sandblasting chamber - which is better

- How to make a camera with your own hands

- Work zone

- Cone bottom

- Cooker hood

- Sandblasting machine

- General building

- Lighting

- Sandblasting recommendations

- Safety precautions

- Choosing a purchased device

Types of sandblasting chambers

On sale you can find two types of sandblasting cameras - inhabited and uninhabited. The main characteristics and operating features of the inhabited cameras are as follows:

- These are airtight rooms of a large area, where the operator is engaged in processing products;

- the walls inside are covered with soft shock-absorbing material that extinguishes the rebound of the abrasive;

- after hitting the surface of the product, the air-abrasive mixture, along with the destroyed particles and processing, is crumbled onto the floor grate, from where it enters the collection and return device;

- the collected mass goes to a cyclone-type separator, is divided into waste and abrasive, which can be reused;

- dust and mining go to the drive outside the chamber, abrasive - to the hopper for further use.

Uninhabited devices are smaller. In appearance, such a camera is a rectangular cabinet in which the master pokes his hands through special holes and carries out all the necessary actions. In such devices, small-sized products are processed, and it is they that can be made with your own hands.

to contents ↑The device and principle of operation of the camera for sandblasting

Sandblasting machine helps to solve a large number of tasks. It cleans any surface - metal, wood, concrete, brick, it is only important to choose the right device power and type of abrasive. After sandblasting, the service life of the products increases, which is especially true for metal. With the help of sandblasting, you can degrease surfaces, prepare them for further work, clean glass before decorating, matt items and even artificially age their surface.

At home, small uninhabited cameras or tubeless pistols that work outdoors are usually used. It is unrealistic to equip houses in the garage with a habitable camera - this is a complex, expensive system that belongs to the industrial category.

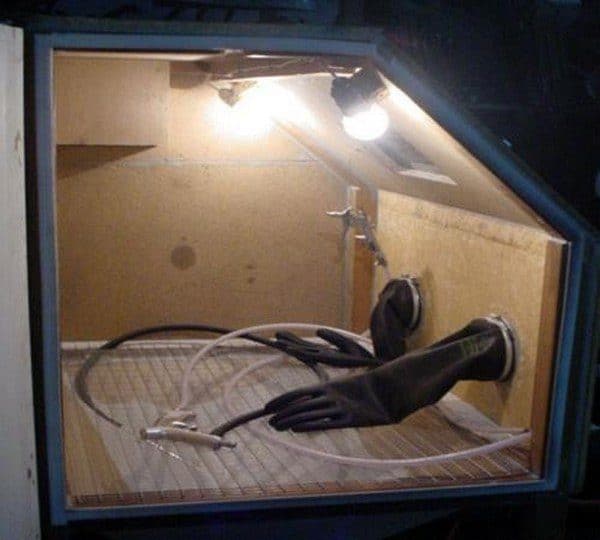

The device uninhabited camera is simple. This is a metal cabinet with a beveled lid with a built-in viewing window. In the front wall there are 2 round holes with sealed cuffs into which the operator inserts his hands. On the floor there is a grill for pouring waste mass. For ease of abrasive removal, the lower part of the chamber is made in the shape of a truncated pyramid. Dust passes through a filter through a filter into a dust collector. Products are loaded into the chamber through a door on the side surface.

The principle of the camera is as follows:

- after turning on the compressor, the air in the unit is connected to the abrasive material;

- under high pressure, the mixture is fed to the surface of the product through the nozzle of the gun;

- the base is cleaned of dirt, plaque, coatings;

- bulk mining enters designated tanks;

- the surface of an object is blown with air for final clarification.

Depending on the type of sandblasting gun, the supply of air with an abrasive can occur in different ways. If the gun is an injector, then sand and air go to the device through different hoses. When the gun is pressure, air and abrasive are mixed in advance and sent to the nozzle along one sleeve. Due to their low cost and ease of use, injection systems are used in uninhabited cameras an order of magnitude more often.

to contents ↑Buy or make a home-made sandblasting chamber - which is better

It is unrealistic to make an inhabited camera yourself - this is possible only in the factory after careful design. The total cost of such installations starts from 1–1.5 million rubles, they include a steel or sandwich panel case, a gateway with swing gates, grating, complex ventilation, lighting, control systems, etc.

to contents ↑An uninhabited camera can be made on its own, while it will work no worse than the purchased one. Expediency depends on the availability of tools, materials, devices: if everything has to be purchased separately, it is easier to buy a finished camera in a specialized store.

How to make a camera with your own hands

A small fixed camera does not take up much space, it can be stored and operated in a garage, shed. In fact, this is a box of metal or other material sheathed with metal with a thickness of more than 1 mm. It is best to place the finished camera on a table or other stand - so it will be comfortable to work with it.

Work zone

Under the working area understand the inside of the chamber, which is closed during cleaning, in which the product is placed. On the floor of this zone, there must necessarily be a grid or grate so that the sand does not linger inside and falls through the bottom. The device must have a viewing window through which the operator can observe the process and evaluate the results.

to contents ↑Good lighting is planned at the top of the work area so that no dark areas remain. Lamps must be made closed, otherwise dust and sand will quickly spoil all contacts. Inside the case there are gloves attached with a clamp on the flange, as well as a sandblasting sleeve with a nozzle (in the pressure chamber) or a gun (in the injection chamber).

Cone bottom

The bottom should be large, otherwise mining with an abrasive will not be able to accommodate and will become layered, accumulate slides. To easily remove waste, you need to provide unhindered access to the bottom (it is most convenient to pour abrasive and dust into an ordinary bucket). If the camera suggests the possibility of reuse of the mass, and its collection is automatic, the bottom walls should be sloping.

to contents ↑Cooker hood

The hood creates a vacuum of air and removes dust from the sandblasting chamber. It must be equipped necessarily, because part of the sand or other abrasive material after impact on the surface of the product is destroyed and turns into flying dust. To equip the hood, it is recommended to use an electric motor with a power of 0.3-0.75 kW with a blade screw.

Sandblasting machine

The basis of the entire system is the sandblasting system itself, which also processes various surfaces. Injection pistols are considered the most common, working according to a simple principle: compressed air is supplied separately from the sand, and the latter flows by gravity from a separate tank through its own hose. Typically, such devices are used for treating delicate surfaces - removing small impurities, frosting glass. The injection device will also remove a thick layer of paint and rust, but 3-4 times slower than the pressure head.

Pressure-type sandblasting apparatuses have an air line divided into two parts: one goes to the container with an abrasive, the second to the exit from it. After ejection of sand under pressure, it combines with the flow of compressed gas, while the acceleration of particles will be maximum. With such processing, the speed of actions is an order of magnitude higher.

to contents ↑General building

This sandblasting section connects attachments, device controls, and electrics. Arm holes should be located at a convenient height for the operator, while the distance between them must also be optimal. The most comfortable diameter is considered to be a hole diameter of 10-12 cm, and it is precisely this size of gloves that should be selected.

to contents ↑Sandblasting gloves should be strong, tight, because they have to protect their hands from rebounding. For their fastening, it is better to choose flanges that, after putting on the gloves, are clamped with clamps. At the top of the common building there is an air damper through which clean air will flow.

Lighting

Lamps should illuminate the work area evenly so that all areas of the workpiece are clearly visible to the operator. To protect the lamps from shock and dust, they are covered from above with a plastic casing, and to maintain transparency, a fine-mesh mesh is placed on the outside (the same device should be mounted on the viewing window). Usually, two light bulbs are enough for high-quality lighting of a medium-sized camera.

to contents ↑Sandblasting recommendations

Before you start creating a camera with your own hands, you need to develop its design and draw up a drawing. This will allow you to specify the dimensions, purchase and correctly measure the materials. The internal parameters of the device do not need to be made too large so that there is no effect of a strong rebound and additional blows of the abrasive to the product. If the camera nevertheless comes out dimensional, it is necessary to sheathe its walls from the inside with soft material, for example, rubber. Other tips for creating a sandblasting chamber are as follows:

- it is necessary to pay close attention to the quality of ventilation of the installation;

- for the installation of the viewing window, it is advisable to purchase impact-resistant plastic, since simple glass will break quite quickly;

- it is recommended to lay a reinforced mesh on the bottom of the chamber, place a durable groove for spent abrasive under it;

- for placing any products in the chamber, including those having a non-standard shape, the sides should be tightened with a tarp, and not made rigid.

to contents ↑

Safety precautions

In order not to harm yourself and others when working with abrasive materials under pressure, do not forget about safety:

- for work you should wear a closed, durable suit;

- the person must be protected with a respirator;

- shoes should also be completely closed.

Choosing a purchased device

If you decide to purchase the camera in finished form, you should carefully consider its characteristics, type, purpose. For periodic household cleaning of parts, you can buy an injection sandblast; for a large amount of work, it is better to spend money on a pressure chamber. When there is a professional use of the device, it is recommended to pay attention to pressure instruments with automatic abrasive recovery.

The stronger and better materials for manufacturing the device, the longer it will last, so it makes no sense to buy the cheapest models that can break after the first use. If you want to save money, you can still make a sandblasting camera yourself - it will be quite enough for household needs, hobbies and repairs.