To remove dirt, dust, old coatings from surfaces, different cleaning agents are used - sandpaper, metal brushes, sponges, rags. But such work is laborious when it comes to large areas. In addition, after manual processing, products often remain scratched and lose their visual appeal.

- Technology application

- The principle of the sandblast gun and the main abrasives

- Sandblasting device

- Types of sandblasting

- Models with a tank

- Hose units

- The choice of gun according to technical characteristics

- Advantages and disadvantages

- Manufacturers and prices

- Homemade Pistols

The best solution is to use more gentle and convenient methods, such as sandblasting. She will need a sandblasting gun that cleans and grinds surfaces using sand.

Technology application

The sandblasting gun is a device for abrasive processing of various materials, surfaces, objects. As an independent device or in conjunction with a sandblasting chamber it is used in construction and repair, metallurgy, instrument making, automotive industry, and a number of other industries.

The device is in demand for different types of work:

- rust removal before applying anti-corrosion compounds, other protective agents or to extend the life of the products;

- grinding wood, metal, plastic, stone, ceramics (objects, blanks, individual components) before decorating;

- cleaning from dirt, old coatings;

- frosting glass to give an opaque effect (dishes, showers, windows);

- degreasing of metal before coating with varnish, paint;

- drawing drawings on glass, other materials;

- cleaning parts of complex shape;

- restoration of art objects;

- roughening materials to enhance adhesion with various coatings;

- artificial aging of wood - furniture, decor, interior elements;

- cleaning the car body from dirt, old coatings before painting.

to contents ↑A sandblasting gun is indispensable for cleaning various curved parts: manually, you can spend a lot of time on this process, and the quality of product preparation will not be the best. When using sandblasting, even hard-to-reach areas will become perfectly clean and polished in a short time period.

The principle of the sandblast gun and the main abrasives

Cleaning, grinding, polishing or matting of different surfaces occurs under the influence of a powerful stream of sand, which moves due to the pressure of compressed air. Sand is fed by a narrow stream, the direction of which can be adjusted. As a result of sandblasting, the excess layer is removed from the surface, it becomes smooth or, on the contrary, rough (depending on the type of abrasive).

Most often, quartz sand of various fractions is used as an abrasive material: fine polishes the base fine, coarse - removes persistent dirt, rust, performs a network of grooves and improves adhesion to coatings.Sandblasting with river sand is even cheaper, however, it does not make sense to use it in pistols with an abrasive recirculation system: the granular mixture is destroyed when it hits the surface and cannot be reused. They do not give dust and provide a much better quality of processing metal shot, nickel slag, kuperslag, corundum, but their price is an order of magnitude higher.

to contents ↑Sandblasting device

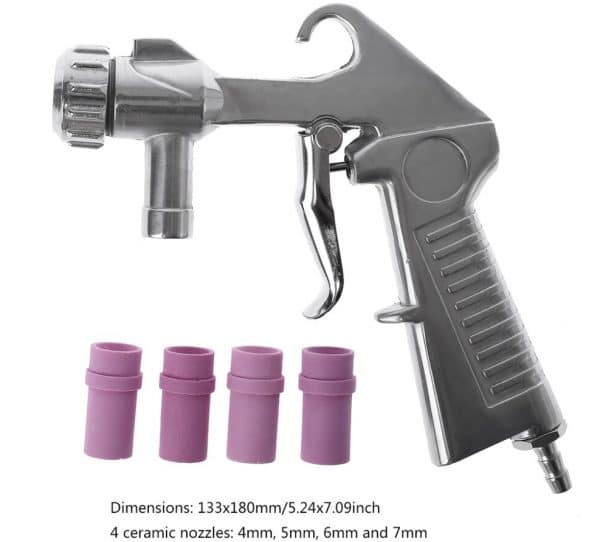

Sandblasting guns for the compressor consist of a number of typical elements:

- housing;

- nozzle with handle;

- control sleeve;

- connection for air supply with or without a tap;

- container for sand;

- sleeve for the passage of the abrasive;

- union nut or threaded pin;

- threaded sleeve.

A carefully calibrated nozzle is mounted on the casing - it must correspond to the pressure that occurs at the outlet of the compressor. The diameter of the nozzle narrows along the air flow, so the part is a truncated cone. The control sleeve controls the current flow rate of the abrasive, the threaded sleeve secures the sand container, the union nut eliminates sand leakage during operation. Some devices also include a separate abrasive dispensing assembly that replaces the threaded sleeve.

After the sand tank is connected to the device, a compressor is connected, then with the help of the control sleeve the operator regulates the air flow pressure and, accordingly, the sand supply force. Here are the main indicators of air flow, taking into account the inlet and outlet nozzle size:

- for diameters of 6 mm and 2 mm - 0.2-0.3 cubic meters. m / min;

- for diameters of 8 mm and 3 mm - 0.3-0.6 cubic meters. m / min;

- for diameters of 10 mm and 4 mm - 0.6–1.2 cubic meters. m / min;

- for diameters of 12 mm and 6 mm - 0.9–1.8 cubic meters. m / min.

to contents ↑Some models of guns have a remote control, and you can work with them from a distance. Cheaper models have manual control, and the operator should always be near the device. The capacity of sand tanks is usually 0.5–300 liters or more, and pistols with the largest tanks are much more expensive.

Types of sandblasting

By functional features, pistols can be divided into the following groups:

- Chamber. They are used for processing small products from glass, metal, ceramics and other materials. Before work, the item is placed in an insulated container - a sandblasting chamber of a certain size, which is connected to the gun.

- Tubeless. They have an open design, are not equipped with a camera, but can be used to process large areas.

Models with a tank

Tank models of guns outwardly resemble a standard airbrush, only sand, not paint, is placed in the tank. They are best suited for small workloads. Pistols with a tank are often used in car services to remove paintwork and rust from the car body. Also, tank devices are well suited for getting rid of oil stains, soot. In everyday life, with their help, souvenirs, dishes made of glass and metal are cleaned, returning them shine and smoothness. In the metallurgical industry, tank guns help remove scale from steel.

to contents ↑Hose units

Similar models have two hoses - one delivers air from the compressor, the second is needed to eject the abrasive. The air-sand mixture is formed directly in the gun body after taking the abrasive from a separate container. Since there is no attached tank, the gun will be more convenient to use mobile and compact, it is perfect for a large amount of work. Most often, appliances with hoses are used for:

- glass frosting in industry;

- creating complex patterns on mirrors, doors, furniture;

- cleaning metal from old paint;

- cleaning concrete walls from plaster and dirt.

The choice of gun according to technical characteristics

To buy a high-quality device for sandblasting, you need to pay attention to such parameters:

- Performance.This indicator reflects the volume of air in liters, which under pressure passes through the compressor per unit time.

- Air pressure. Typically, a pressure of 6-8 atmospheres is enough for high-quality processing of concrete and metal products, 3-5 atmospheres are enough for decorative work. Since the pressure in the compressor and at the outlet of the gun is not the same, the hose and nozzle must have different diameters.

- Compressor power, revolutions / minute. These parameters also affect the overall performance of the device and must be taken into account when buying.

For processing complex products, you should choose a gun that works with the highest possible pressure (usually 10 atmospheres), but it is not suitable for delicate substrates - surfaces can be badly damaged. Other technical parameters that you should pay attention to are:

- nozzle material - the most durable parts are those made of alloys with the addition of cobalt, tungsten carbide (ceramics and cast iron deteriorate much faster);

- type of nozzle attachment - a threaded pin is considered more reliable, since the union nut can weaken from constant vibration over time;

- ergonomics of the handle and shut-off and control valves - the more convenient it is, the easier it will be to work with a gun;

- the presence of mounting holes - they can be used to fix the gun, and move the workpiece relative to the device itself.

Advantages and disadvantages

The advantages of sandblasting guns are as follows:

- the availability of different models - from budget in price to professional, performing a large number of works;

- various sizes and designs - if desired, you can choose a compact device that does not take up much space;

- the ability to clean and prepare for processing even complex parts and hard-to-reach areas;

- simplicity of operation, ease of control - even a beginner can literally learn to use a gun from the first treatment;

- the ability to make it yourself - a simple sandblasting gun is easy to do with your own hands from improvised materials and devices;

- time saving - surface cleaning is quicker than manual preparation.

The disadvantages of using pistols are also there, although they are few. The life cycle of cheap models is limited, but more expensive devices usually work well for many years, and there are accessories for them in company stores. Sandblasting guns make noise during operation, while more powerful models make more noise.

If you work with a gun without protective equipment, you can cause serious damage to your health. This is especially true in situations where sand is used as an abrasive: its dust causes an incurable lung disease - silicosis. Dust settles on the surrounding surfaces, so they must first be covered with a durable film or taken out of the room. Otherwise, you will have to spend a lot of time cleaning.

to contents ↑Manufacturers and prices

The most popular brands of sandblasting guns are Metabo, Makita, although due to the high price (from 5000 rubles) they are more often chosen by professionals. For domestic purposes, you can buy pistols "Sorokin", Skrab, Voylet, Matrix, SGI, which cost from 800-1000 rubles and have good technical characteristics. GI-Auto pistols that are permanently fixed on any surface are of excellent quality, but their price is from 3000 rubles.

A well-known model is the Wester SSP 10 (1200 rubles) - a sandblasting air gun with a small 750 ml tank, which is perfect for removing rust, frosting glass, and grinding small surfaces. Also popular among sandblasting masters is the “Russian Master” PM-99191 with an abrasive recirculation system that is suitable not only for quartz sand, but also for corundum, nickel slag, kuperslag and allows you to reuse abrasives.

to contents ↑Homemade Pistols

Such devices are made by the master independently at home. They belong to tank pistols, and a plastic bottle of 1–5 liters is used to store sand in them.The nozzle will have to be purchased ready-made, because you can’t do it yourself. This part must be made of durable material, as it is exposed to sand and compressed air pressure. Additionally, you should buy a set of tips for the nozzle - even the highest quality ones will have to be changed regularly.

The sandblasting housing must match the size of the nozzle. Two hoses are attached to it, which should also be purchased: one goes to the bottle with sand, the second joins the compressor. Instead of a body, a water tee can be used. The compressor for the gun must have a receiver, which ensures a uniform air supply with a stable pressure.

For processing metal and concrete, a powerful compressor will be required, for wood - a medium or small capacity device. Sand before laying in the device must be washed, dried and sieved several times, otherwise the gun will quickly break.

In view of the moderate price of many models, it is worthwhile to calculate the costs of components before self-production: it may be better to buy a ready-made device. In any case, the quality of product processing will be similar, so you have to make a choice yourself.