Sandblasting apparatus is used for processing, cleaning from contaminants and grinding products from metal, wood, concrete. The design of this device is not complicated, but it necessarily includes several main nodes.

- Design features of a nozzle for the sandblasting device

- How to choose a nozzle for a sandblasting machine

- Type of sandblasting nozzles

- Nozzle boron carbide GN UBC

- Nozzle boron carbide GN UBC XL

- Nozzle boron carbide GN DVBC

- Material and design of the internal wear-resistant insert

- Container design and nozzle assembly quality

- How to make a budget nozzle for sandblasting yourself

The sandblasting nozzle is a hollow pipe with a thread designed to feed the abrasive mixture to a contaminated surface. If you wish, you can make a nozzle with your own hands, although the highest quality nozzles can only be purchased in finished form.

to contents ↑Design features of a nozzle for the sandblasting device

Any sandblasting nozzle looks like a pipe, which at one end is attached to the nozzle holder. The profile of the inner hole of the part determines the consumption of the abrasive mixture, its possible losses, the speed of movement at the inlet and outlet. The total hydraulic resistance depends on the nozzle profile, therefore, the service life of this important part of the sandblasting unit.

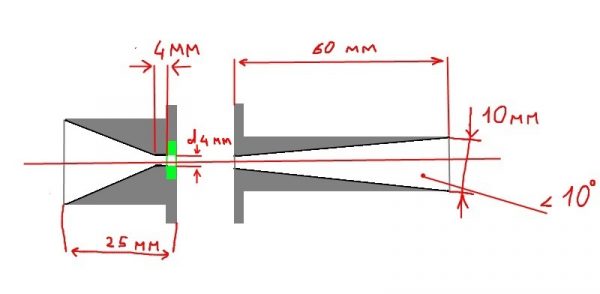

Most often there are products with a cylindrical inner hole, which are considered the simplest in design. The most effective in operation are recognized tubes with two conical sections:

- input confuser, increasing the energy of the flow of air-sand mixture;

- output diffuser, increasing the surface area undergoing processing at the same time.

Venturi nozzles having the best profile of the internal hole provide the minimum possible loss of air-sand mixture. There are three connected sections inside the hole: in addition to the two conical sections, there is one more cylindrical part, which helps to reduce the hydrodynamic resistance of the working mixture. Such tubes make it possible to develop an abrasive jet speed of up to 720 km / h, while conventional devices with an equal diameter of the inner hole along their entire length are not able to provide a flow velocity of more than 320 km / h.

Ready-made serial nozzles have standard diameters: 6 mm, 8 mm, 10 mm, 12 mm. The higher this indicator, the higher will be the power of the jet produced by the sandblasting unit. The approximate power of the device with a minimum size nozzle (6 mm) is 30 cubic meters. m / hour.

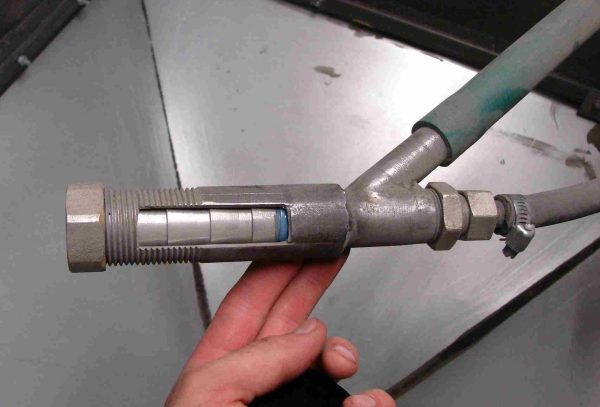

The inlet diameter at the hose connection point is 2.5 or 3.2 cm as standard. The nozzle is connected to the nozzle holder using a connecting thread, or through a union nut and a sealing washer. If the part is made independently, it is attached to the sleeves (hoses) with clamps.

How to choose a nozzle for a sandblasting machine

In addition to the type of hole and diameter, the most important technical parameters of the nozzle, which directly determine its operation, are:

- length;

- manufacturing material.

The length should be selected depending on the degree of contamination of the surface to be treated. If rust, dirt, plaque are not too thick, you can choose a short part (7-8 cm).For surfaces with difficult to remove, complex, thick layers of dirt buy longer tubes (up to 23 cm).

To create a nozzle with your own hands, a variety of materials and improvised devices are used. As for purchased products, they can also be completely different with respect to the basis, while the service life will vary greatly:

- ceramic - 2 hours;

- cast iron - up to 8 hours;

- tungsten - up to 300 hours;

- from boron carbide - up to 1000 hours.

The durability of the nozzle depends on the type of abrasive material: for example, when replacing sand with steel shot, the service life increases by 2.5 times. Inexpensive products usually fail most quickly, so they are completely unsuitable for a large amount of work. For a single domestic use, you can buy a ceramic or cast-iron nozzle, or a set of them, to replace as necessary. Professionals use tungsten carbide or boron carbide parts that are expensive, but with regular use are much more economical.

Do not buy steel nozzles - ordinary carbon steel is not very suitable for the manufacture of nozzles for sandblasting machines, as it is very sensitive to shock loads. Tungsten products also have their drawbacks: they do not tolerate heat well and can crack at a temperature of + 80 ... + 100 degrees. Parts made of boron carbide in this respect outperform others: they can deteriorate only at + 600 ... + 750 degrees, which is unlikely during sandblasting. But their price reaches 1600-7000 rubles, because they are not too accessible to non-professionals.

to contents ↑Type of sandblasting nozzles

The nozzle channel directly affects the acceleration speed of the abrasive and air flow and the performance of the entire installation. Products with a straight-through (straight-through) channel are usually used for processing small surfaces or narrow parts. The most effective are nozzles, the diameter of which varies depending on the site, but does not remain constant.

to contents ↑A typical representative of quality products are Venturi nozzles. They help enterprises improve the quality and efficiency of work, reduce time and labor costs, as well as the cost of cleaning. For their use, you do not need to change the abrasive (any one will do) or increase the compressor power.

Nozzle boron carbide GN UBC

These are the most common sandblasting nozzles on the market. They create a wide imprint of abrasive particles, allow you to develop high speed, high kinetic energy. Commonly used to perform a significant amount of work.

to contents ↑Nozzle boron carbide GN UBC XL

The channel length in such products is 3.5 cm, their productivity is 30–50% higher than in the previous ones. The price of the nozzles is quite high, and for a small amount of work they will not work because of the strong dispersal of abrasive particles.

Nozzle boron carbide GN DVBC

The Double Venturi technology utilizes the ejection effect - when air from the atmosphere is introduced into the abrasive stream. The diameter of the tube outlet here is larger than in the classic version, and the sand stream is supplied with maximum kinetic energy. To use such a nozzle, an installation with a powerful compressor, long sleeves is needed, and it is advisable to use it only on large machined surfaces.

to contents ↑Material and design of the internal wear-resistant insert

As for the material for manufacturing the inner part of the nozzle, it can be inexpensive, but short-lived, or better, but expensive. The most popular for this purpose are carbides of boron, tungsten and silicon. Due to the difference in the processing technologies for these materials, the nozzle designs can be very different from each other (for example, it is impossible to make a cylinder more than 7 cm long from boron carbide, which determines the design features of the nozzles - they have to be made up of several elements). The wall thickness of the inner sleeves also varies from 3 to 6 mm, which affects the resistance to abrasion.

to contents ↑Container design and nozzle assembly quality

The product shell is needed to fix the wear-resistant sleeve, to protect it from rapid damage. It is the shell that accounts for most of the shock loads, so it is more susceptible to wear. In order for the nozzle service life to be sufficient, the protection should be made of abrasion-resistant material, attach tightly to the sleeve, and have a reliable thread.

There are such types of shells:

- Polyurethane Lightweight, resistant to damage by abrasive, but due to its low stiffness, its thread wears out pretty soon. Due to poor adhesion of polyurethane to the basic materials for the manufacture of bushings, the latter begin to move, air penetrates between them, and the protective shell deteriorates.

- Metal (steel, aluminum). Reliably fastens wear-resistant bushings, but its resistance to abrasive is low. The shell suffers from corrosion, too heavy in weight. A structure with such a part will be stiff, but can quickly become damaged.

- Combined (aluminum plus polyurethane). It is considered the most popular option, tough, but lightweight, has a thread with a large pitch. The front polyurethane protects the product from abrasion. It is only important to firmly fix the shell inside the sleeve, otherwise the nozzle will begin to collapse.

to contents ↑Build quality also plays an important role in the life of the entire structure. On sale there are low-quality nozzles, where the body and the threaded part are pressed into each other. Most often they quickly deteriorate, and at pressures above 8–10 bar they can even cause a person injury or damage to the entire sandblasting apparatus. The most loaded part of the nozzle must be turned out of the whole workpiece, otherwise the threaded area will vomit during operation.

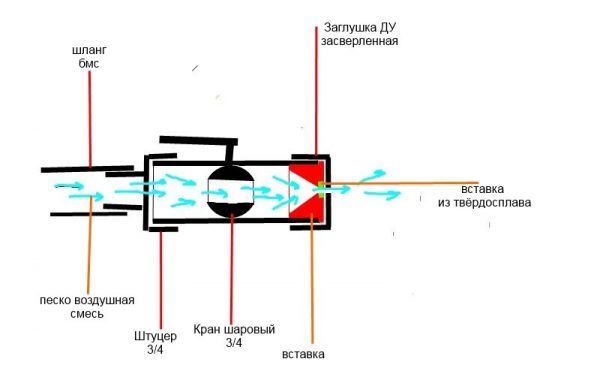

How to make a budget nozzle for sandblasting yourself

If the nozzle of the sandblast installation has become unusable, you can make a replacement yourself. True, the continuous life of such a product will be short, but the cost of consumables will not hit the budget. The main nozzle may be a ceramic spark plug or an old ceramic resistor with an inner diameter of 2-4 mm.

The procedure for working with a resistor is as follows:

- hats, legs to tear off with nippers or saw off with a grinder.

- take a metal bolt M14, cut off the top, drill a through hole with a No. 5 drill.

- deepen the hole with drill No. 8 by about 1.4 cm.

- weld a wide M5 washer on top of the M14 clamping nut, make a cone from the inside with a No. 8 drill, pressing on the future nozzle.

To create a nozzle from a spark plug, proceed as follows:

- using pliers, pull out the contact rod from the candle, preheating it with a gas burner.

- grind the rolled edge of the candle body on the machine.

- knock out ceramic insulator.

- with a sharpener to cut the edges of the nut, remove it.

- cut off part of the ceramic insulator with the diamond wheel where the central electrode is located.

- Attach an adapter with a clamping nut purchased or pre-machined from a bolt to the shaft.

On sale there are a variety of nozzles for sandblasting, and the service life and performance of the most modern products will be several times higher than that of self-made ones. With regular use, sandblasting makes sense to purchase a quality part in a finished form, and for a one-time operation if you have the necessary equipment and skills, you can make a nozzle yourself.