The tradition of building a wooden bathhouse in summer cottages or in country houses has been around for quite some time. This material is safe for human health, but due to its natural properties it is prone to decay, the development of fungus, mold. How to process the bath to avoid this?

- Floor protection

- Structural protection

- Chemical protection

- Door leaf protection

- Shelf and bench processing

- Processing of ceiling and wall panels

Floor protection

Wood is traditionally used for flooring. Organic substances contained in the material make it less resistant to various negative factors. This can be minimized with the help of special formulations.

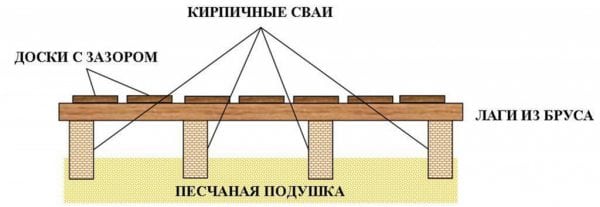

The design of the floor requires a lag. Due to their location, they are protected from direct sunlight, temperature changes, direct contact with water. But saunas are areas of high humidity. Therefore, condensation, capillary moisture, living organisms are factors that adversely affect logs.

When a bath is being processed, building codes define two types of measures aimed at protecting wooden elements.

to contents ↑Structural protection

The correct arrangement of the underground space is the key to the absence of rotting of the board due to condensation. In particular, it involves ventilation equipment between flooring and logs. Also, mechanical hydroprotection is used for protection. It consists in the use of gaskets from bitumen-containing films.

Chemical protection

Impregnation of floor beams has antibacterial value. Logs are best treated with water-washable formulations, since these parts are not directly exposed to precipitation, regular washing (especially by aggressive means). The biological protection of lag baths, saunas is carried out by an antiseptic, which basically has linseed oil, a solution of wood resin, copper salts, urea. Processing with beeswax gives a good result. These compounds in combination with properly made ventilation protect the logs from decay.

It should be remembered that it is better to warm the oil compositions before application.

It is important to remember that to cover the boards in the bath with machine testing is not the best solution. Excessively high chemical activity is not suitable for conditions of constant humidity of the sauna.

Traditionally, sauna lags are recommended to be treated with solutions whose composition contains borax, silicate glue, potassium dichromate, vinegar. Today on sale there are compositions that can be called an antiseptic with broad functions:

- protection against damage by living organisms;

- giving wood fire resistant qualities.

Compositions that process the logs of a bathhouse or sauna should not lead to significant shrinkage of wooden elements. At the same time, the maximum closure of the pores of the ends of the boards is their main task. Factory mixtures are applied exclusively in a cold manner in several layers.After the impregnation is completely dry, the wood should be coated with polymer paints.

to contents ↑Door leaf protection

In the sauna, as a rule, several rooms with different purposes. To separate the washroom from the locker room, you can use the door. This element requires special care aimed at preserving the original appearance, extending the life of the product. For wooden paintings, this requirement is of particular importance.

Doors purchased for saunas most often already have rotting treatment. Therefore, additional impregnation from moisture is not required. Most often, the canvas is painted.

How to paint the doors leading to the sink? The coloring matter must meet the following requirements:

- protect the tree from the temperature of the sauna;

- extend the term of operation;

- provide aesthetic appeal.

To paint the door, it is recommended to use special varnishes for wood. They have the following advantages:

- high level of vapor permeability (similar to antiseptic treatment);

- the ability to re-paint the surface;

- a wide selection of pigments that can emphasize the natural texture of wood.

Often a stain is used to process a door made of natural wood, which also helps to solve the task of protecting the surface. It is important to remember that major flaws are puttied with a special compound. Its color is selected in accordance with the shade of the used varnish, oil or stain.

to contents ↑Shelf and bench processing

Saunas and saunas are not possible without ropes or shelves. Like other parts of the structure, they are made of wood. It should be remembered that the same impregnations cannot be used for them as for the floor, walls or ceiling. As you know, the steam room conditions imply strong heating of all surfaces. In contact with a hot bench, unprotected parts of the body, a person can get a severe burn. Therefore, the impregnation should not form films.

Processing of wooden shelves in the steam room can be done with oil formulations designed for saunas. A universal protective composition with wax is also suitable. Example: Supi Saunavaha manufactured by Tikkurila. This impregnation is suitable for processing almost all surfaces of saunas: window frames, walls, shelves, and ceilings.

to contents ↑Processing of ceiling and wall panels

When deciding how to process the bath inside, attention should definitely be paid to the surface of the walls and ceiling. The choice of impregnation is determined by the material used. Most often it is logs or lining (not wide boards of natural origin). For them, you can choose special varnishes. The advantages of these compounds are to preserve:

- appearance;

- useful properties.

For walls and ceiling, this is of great importance. After all, their surface is exposed to high temperatures, sweat. Poor-quality impregnations will not protect against decay, they can negatively affect the health of people in the sauna. Acrylic based formulations are recommended. They can be used without fear in high temperature conditions - an unpleasant odor will not be felt.

Processing the walls and ceiling with varnish, the user eliminates the need to carry out preparatory work. If you cover the surface with protective compounds, later it will be easier to wash.

It is important to remember that when visiting a sauna, a person touches unprotected parts of the body of not only shelves, but also walls. Therefore, for the treatment of flights, benches and adjoining parts of the wall, experts recommend choosing compositions that exclude excessive heating. To facilitate the work, you can apply them to the entire canvas walls.

The ceiling does not require such a careful selection of materials. It can be coated with compounds that give the material resistance to moisture, temperature, and allow it to breathe.How much the surface will heat up does not matter.

The purchase of paints and varnishes to cover the logs from the inside of the room is preceded by a careful study of the composition and properties. For example, the mixture "Sauna" has antiseptic qualities. The formed polymer coating protects the ceiling and walls from moisture, repels pollution.

Processing the ceiling and wall surface with the Natura mixture, the consumer receives a room with a natural wood color. Although you can give the walls any other tone.

Do you want the ceiling to shine? A mixture of Supi Arctic is suitable for this task. It is suitable for walls. In addition to shine, the ceiling will be endowed with good dirt-repellent properties. The composition is also easily tinted.

All surfaces of the bath should be treated with special compounds. This will help extend the life of the room, eliminate the likelihood of rot development.