Wood - a noble material, has long been used for the manufacture of various products: furniture, home decor, dishes, useful things in the household. A noble color, a pleasant aroma, a beautiful pattern of fibers - the qualities of wood, which she became famous for. But there is a significant drawback that cannot be written off. Moisture is destructive for this material, since it causes great damage: it leads to fiber separation, swelling, deformation. Stabilization of wood helps prevent this.

- What is wood stabilization?

- The main objectives of stabilization

- Cured material properties

- Benefits of the procedure

- Wood stabilizing compounds

- Epoxy resin

- Liquid glass

- Brine

- Drying oil

- Composition for the vacuum chamber

- Birch juice

- Polymers

- Anacrol-90

- 100term

- Burawid

- Pentacryl

- Stabilization process

- Step-by-step processing of wood “Anacrol”

- Epoxy resin treatment

- Oil impregnation

- Polymerization acceleration

- Cleansing composition

- Color change

- Self-painting errors

It's about manual processing with special compounds. They strengthen the fibers, make them more durable, durable, strong. The main thing is stabilization reliably protects the wood from moisture: even prolonged contact with the liquid does not do any harm. The tree becomes like stone, preserving the natural charm.

What is wood stabilization?

This process is a kind of conservation. In the structure of wood, internal processes stop. The product remains forever as it was at the time of stabilization.

Due to the high cost of consumables, time and complexity, this procedure is practically not applied on an industrial scale, but is excellent for processing small items:

- furniture;

- crafts;

- toys;

- interior / exterior items;

- handle knives.

The main objectives of stabilization

The primary task is to protect the wood from the negative effects of moisture. After impregnation, the fibers become immune to all kinds of liquids and chemical treatment. They do not increase, do not lose their operational characteristics, retain their shape and color.

This procedure is not just impregnation, but the filling of the entire available space between the fibers. To do this, protective compounds that clog pores are used.

Stabilization helps improve the consumer qualities of wood. The best effect can be achieved with compositions with the ability to polymerize. Most often for this purpose apply:

- natural resins;

- polymers;

- paints and varnishes;

- all kinds of oils.

Cured material properties

Proper soaking at home helps to achieve the following results:

- Wood gains increased strength.

- The density of the fibers increases. Less voids and cavities appear in the structure.

- Products become immune to external influences, sudden changes in temperature, increasing the level of relative humidity.

- The surface gains resistance to ultraviolet radiation. It does not fade in direct sunlight, remaining surprisingly beautiful.

- Crafts and furniture are insensitive to short-term flame effects. Strong heating does not lead to deformation.

- High density prevents the penetration of oils and all kinds of solvents deep into the structure.

Despite this, the stabilized wood remains malleable. It can be sawn, grinded, cut, ground, polished. This expands the possibilities for the manufacture of decorative products.

to contents ↑Benefits of the procedure

Unlike other methods of wood processing, stabilization allows you to achieve a lasting effect. Varnishing, for example, creates a protective layer only on the surface. And filling the pores with compositions with polymerizing properties provides complete processing throughout the structure, strengthening it from the inside and out. As a result, wood gains more effective protection against external factors.

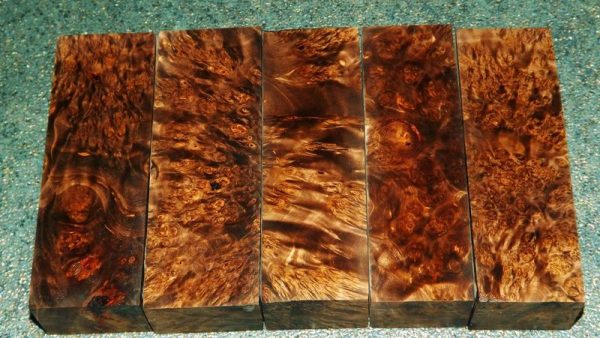

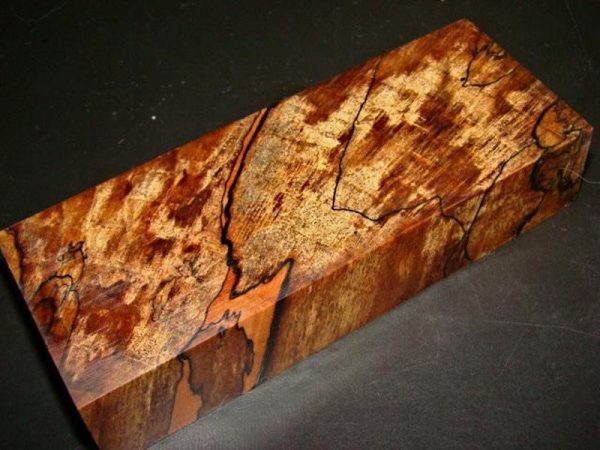

There is another interesting factor. Stabilized wood in its structure is more like a natural stone. Her cut pattern is similar to marble. It affects the process of filling pores with a specially selected agent.

to contents ↑

Wood stabilizing compounds

The desired result can be achieved with various materials and compositions. Some are cheaper, others are more expensive. In order to easily determine the ideal tool, you should consider each option in detail.

Epoxy resin

Suitable for almost all types of wood, except coniferous. Before impregnation, it is necessary to verify the normal fluidity of the material (the speed and density of pore filling depend on this). The desired result can be achieved with an alcoholic resin solution, but its preparation is a laborious procedure.

If the polymerization process takes place in a vacuum chamber, there is a possibility of boiling epoxy resin. This is its natural property along with low fluidity.

to contents ↑Liquid glass

It is actively used in everyday life, as it is affordable and does not cause difficulties with use. After wood processing liquid glass a protective film is formed on its surface that is resistant to various dyes.

This composition is used to stabilize decorative products, structural elements that are not subject to further processing by protective compounds in the future. Liquid glass protects the wood from mold and mildew. It is characterized by resistance to external influences, including UV radiation, increased moisture, high temperatures.

to contents ↑Brine

The cheapest, but least practical way to stabilize a tree at home. The proportions are as follows:

- 1 tablespoon of ordinary salt (regardless of grinding);

- 1 liter of water.

To stabilize, it is necessary to boil a wood product for 2-3 hours.

Drying oil

An ideal solution for stabilizing wooden crafts. Drying oil contains in its composition vegetable oils that have undergone a heat treatment process. This provides increased resistance to moisture as well as direct sunlight. So that the viscosity of drying oil was sufficient for processing wood, a solvent is added to it.

This composition provides protection against the influence of adverse factors:

- decay;

- deformation;

- gradual wear.

to contents ↑If you want to stabilize furniture and decor items, it is better to choose drying oil based on natural components. Alkyd and composite compounds are suitable for processing outdoor products.

Composition for the vacuum chamber

This technology is good in that it provides complete impregnation of wood. Means penetrate deep into the structure of the fibers, saturating them and endowing them with protective properties. At a pressure of 12 kg / sq. cm impregnation is able to penetrate to a depth of 0.3 to 5.0 cm. It depends on the type of wood, its age, density and a number of other factors.

For this purpose, a tool called "Anacrol-90" is used. We will talk about it later, but for now let’s highlight another composition for stabilizing the tree.

to contents ↑Birch juice

Perfect for polymerization. Birch sap does not contain harmful components, toxins, carcinogens, and therefore is safe to use. For deep penetration, it is recommended to use a vacuum chamber, and you can fix the result by drying at a temperature of +90 degrees Celsius.

To achieve a beautiful decorative effect, you can add natural dyes to birch sap. This will expand the possibilities for stabilization.

to contents ↑Polymers

Polymer compositions are excellent for processing wood products, as they have high penetrating power, as well as natural polymerization, which occurs quite quickly. On sale there are a large number of tools that are suitable for this procedure. We have collected the most effective.

Anacrol-90

This is a special composition designed exclusively for stabilizing wood in a vacuum chamber, which you can do yourself using:

- Vacuum pump;

- compressor;

- pressure gauge;

- tubes and taps;

- plastic containers.

"Anacrol-90" is a polyester impregnation, which is converted into a thermosetting polymer under the influence of high temperature. Due to this composition, wood becomes insensitive to strong shocks and the effects of negative environmental factors. In addition, it acquires resistance to chemicals.

to contents ↑100term

Means made on the basis of thermosetting polymers. It is a clear liquid of medium viscosity. Great for wood processing. For the convenience of transportation and storage, it is supplied in cans. Suitable for industrial and home use.

to contents ↑Burawid

This tool contains optical pigments that are responsible for the polymerization of wood. "Burawid" has a slight viscosity, due to which it easily penetrates even into tiny pores.

This composition helps to avoid biological contamination of wood. In addition, Burawid emphasizes the natural fiber pattern, making it more expressive and beautiful.

to contents ↑Pentacryl

It is made on an alkyd basis. In the manufacture of this product add fat-soluble pigments and dyes, which allows you to saturate wooden products and give them a deep expressive color. With the help of Pentacryl, the polymerization process proceeds externally and internally, while the composition does not contain harmful components, and therefore is safe for use at home.

to contents ↑Stabilization process

This procedure requires careful preparation, and in addition, the properties of the selected agent must be taken into account. The stabilization technology directly depends on the composition of the impregnation. For convenience, the most popular polymerization methods will be considered.

Step-by-step processing of wood “Anacrol”

First, you need a container in which the selected workpiece will be completely placed. It must be filled with Anacrol-90 so that the wooden product is buried in it. After this, it is necessary to create vacuum conditions until the air bubbles cease to stand out and appear in the liquid.

Next, leave the workpiece in the impregnation for 20 minutes, and then create an excess pressure of about 2–4 atmospheres. At this stage, you need a compressor or a special pump.

At the end of this procedure, you need to wait half an hour, and then repeat it. If the workpiece sinks in water, then there are no empty pores left in it. If it pops up, it is recommended to repeat the treatment with Anacrol again. The final stage is drying, which can be carried out in an ordinary oven at a temperature of + 90 ... +100 degrees Celsius. To achieve a special effect, you can add color pigment to Anacrol-90.

to contents ↑Epoxy resin treatment

This process is similar to that described above, but the difference in fluidity must be taken into account. Epoxy is very viscous in structure, so it should be diluted with alcohol. In addition, polymerization takes a lot of time, so you need to be patient.

When processing wood, it is recommended that the resin does not boil when a vacuum is created. Otherwise, the workpiece may be damaged, and the result will be unpredictable.

to contents ↑

Oil impregnation

This procedure is much simpler, more convenient and more economical in terms of costs. Oil you can use any:

- sesame seeds;

- nutty;

- flaxseed;

- tung.

Cold impregnation is very convenient and practical, suitable for small workpieces. To do this, it is enough to completely soak the wood. The difficulty lies in the fact that the polymerization process takes from 3 to 14 days, depending on the selected breed. All this time, the workpiece must be kept immersed in oil.

to contents ↑Polymerization acceleration

Sometimes the process of wood preservation is time-consuming, but you can resort to one trick. First you need to carefully dry the wooden blank. This will remove excess moisture from it, and open pores will more easily accept the composition for subsequent polymerization.

Cleansing composition

If the selected product has any inclusions, additives or even small debris, this can damage the polymerization and spoil the workpiece, which is unacceptable. Therefore, it is recommended to filter the composition first. For this purpose, ordinary gauze, folded several times, is suitable. This will delay the impurities, and at the exit will give a clean product suitable for the preservation of wood.

Color change

By adding natural dyes, you can get an amazing effect. The process is suitable for blackening wood, as well as for creating unusual color stains in its structure (not only on the surface). For this, concentrated pigments are recommended. Anacrol will be a great choice.

to contents ↑Self-painting errors

Many beginners make a lot of mistakes in the process of stabilization of wood. The mistake will be to apply the composition with a brush. So its quantity will not be enough to penetrate deep into the fibers, and the processing itself will turn out to be superficial, of poor quality. Over time, cracks may appear inside the product that will lead to deformation.

When working with a vacuum chamber, adhere to an allowable pressure of 2–4 atm and not exceed it. It is not recommended to dry the tree at temperatures above +100 degrees Celsius.

In no case do not have to rush. Be patient and get ready for the stabilization to take a single day. But this approach will help to achieve the perfect result.