Many owners of cottages and country houses dream of having a bathhouse on their site. When deciding on its construction, it should be understood that choosing the plan you like is not the most important thing. The issue is more important than covering the floor in the bath. The answer to it is determined by the type of flooring and the materials used.

- Types of floors

- The right approach to coverage

- Acquaintance with an antiseptic

- Varnishing

- Floor painting

- Concrete Floor Processing

Types of floors

Rooms in which a high level of humidity is noted are combined with two types of flooring:

- concrete;

- wooden.

Concrete floors are used in the washing and steam rooms. Tiles are laid on top, which should be non-slip, suitable for areas with high traffic and high humidity. In order to avoid contact with bare concrete cold concrete, special wooden grilles are also installed. This option is more preferable because it allows you to maintain cleanliness and to avoid the formation of mold. To do this, the lattice is sometimes taken out to dry, coated with special antiseptic agents.

For wooden floors, non-thick bars or boards are used, which are laid on logs of the same material. This type of flooring is recommended for use in the dressing room, as well as in the lounge. The use of wood requires a thorough antiseptic treatment, take care of waterproofing.

What kind of wood is used for baths? Exclusively coniferous. They do not heat up enough to squeeze the resin contained in the pockets and pores of the wood.

Natural impregnation remains inside and thereby extends the life of the tree, preserves its quality, provides reliable protection.

Experienced builders do not recommend using hardwood for floors in the bathhouse, especially oak. Oak, despite its durability and strength, is quite slippery.

The right approach to coverage

If the wooden floor is processed, a clear sequence of work should be strictly observed. This will avoid getting low-quality coating and in the future - decay. Experiments with tools that are used for processing are also unacceptable - they can lead to the need to replace all decks. Therefore, it is better to give preference to trusted manufacturers, even if their funds are not cheap.

The process of coating the surface in the dressing room and the rest of the bath takes place in several stages:

- Treatment with an antibacterial composition.

- Drawing any covering of finishing type.

Acquaintance with an antiseptic

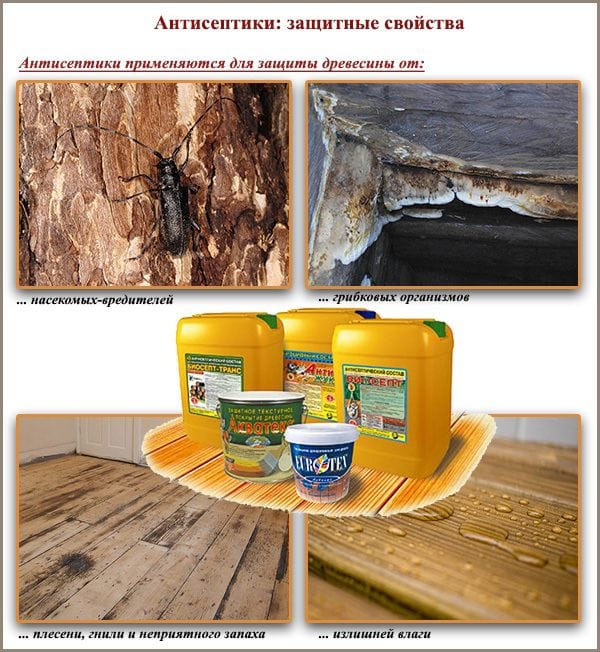

Everything that is made from natural wood must undergo processing with a special agent that prevents the decomposition and destruction of fibers - an antiseptic.

In the bath, as you know, almost all the time, high temperature and humidity are maintained. Such conditions are ideal so that the wooden floor and other surfaces begin to become covered with mold, fungus, rot. Pests can settle in them.

Rules for choosing an antiseptic:

- Belonging to a reputed manufacturer.

- The composition should be designed specifically for baths.

Types of impregnation:

- Water soluble. This tool is best suited for application on the walls in the dressing room and rest room.

- Antiseptic with organic solvent. Gives the surface increased moisture resistance and strength.It can be used for external and internal work. Such an impregnation can also process the floors in the steam room.

- Based on oil. Suitable for areas in which there is no difference in temperature and humidity.

- Combined. They protect the tree not only from decay, but also from fire.

Before applying the antibacterial composition, the wood is cleaned. Also, it should not be wet. The product should be applied in two or three layers, paying special attention to the joints and saw cuts. If damage from insects has been noticed, you should use a special alcohol-based compound. It is poured into the passages with a syringe, causing a small amount to the area around.

to contents ↑It is important to remember that any, even very high-quality antiseptic is washed out over time. This is especially true for baths. To extend its validity, the floor is varnished - but not simple, but with a special water-based.

Varnishing

Varnish is the final step in the coating of wooden floors in any room. The bathhouse is no exception. The difficult operating conditions of this room impose certain conditions on the finishing material:

- surface protection against decay, increased action of an antiseptic;

- fencing of the coating from various damage, especially mechanical;

- should not pose a threat to humans and pets;

- moisture resistance;

- should not overheat and emit harmful substances.

How to paint the floor using varnish:

- Prepare the surface. Floors should be cleaned of dust, stains of grease, traces of old coatings. Using putty on wood, fix irregularities. Be sure to treat with an antiseptic.

- Apply varnish using a brush or roller, allow to dry. It is important to remember that in the steam room, special varnishes should be used, which, when heated, do not emit hazardous substances. They must also protect the premises from fire as a result of sparks from the source.

Floor painting

Often in a bathhouse floors are not only varnished, but also painted. The paint must have the characteristics of a special plan, otherwise there may be a threat to the health of visitors. Of course from steam room painting better to abstain.

So that the material can be used in such conditions that take place in the bath, it must have the following properties:

- as a result of application, a film is formed on a wooden surface, which does not allow dirt, moisture to accumulate and protects against excessive heating;

- resistance to mechanical damage and the appearance of fungus.

The preparatory phase of working with paint is similar to the activities that are required before applying the varnish.

to contents ↑Concrete Floor Processing

Often, in the dressing room, several types of finishing materials are used - wood, concrete and tile. The last two are used in the pool area and locker rooms. Inexperienced bath users believe that concrete floors do not require special treatment. Why is it still necessary to do this? Finishing provides:

- increase in wear resistance;

- getting rid of excessive dust formation;

- increase in term of operation.

It should be noted that the processing is relevant not only for new designs, but also for floors that are already in operation.

Impregnation for concrete, depending on the characteristics of its composition, are divided into two groups:

- Organic Compositions having an acrylic, epoxy, polyurethane base. After the substance is applied, it fills all the pores, increasing the strength of the floor, its moisture resistance and resistance to chemicals. Of the existing foundations, the most functional polyurethane. Its low cost is another reason for the popularity of the product.

- Inorganic. Concrete becomes insensitive to substances of a chemical nature.

How to use impregnation? You need to follow the steps:

- To clear surfaces of pollution and roughnesses.

- Pour the impregnation on the surface, after which it is distributed using a roller so that a uniform layer forms.

- Leave to dry for about three hours.

- Dilute the used composition with water according to the instructions and fill again.

- After the time set by the manufacturer, remove excess impregnation and rinse the floor.

When purchasing a floor cleaner in the dressing room and other parts of the bath, you should be guided by the operating conditions and the type of material. The correct selection of antiseptics, impregnation, varnishes is a guarantee that the coating and the floor itself will be used for a long time.