Decorative impregnation for wood is a special composition that improves the appearance of a wooden product. With the help of impregnation, you can both emphasize the natural beauty of the tree, and imitate other types of wood. For example, a product made from inexpensive pine can be disguised as a respectable oak or rosewood.

- Enemies of wood

- The mechanism of action of impregnation

- Fire protection

- Decorative impregnation

- Classification of impregnations by composition

- Impregnation characteristics using the Galamix example

- Material consumption

- Surface preparation

- Impregnation

- Conclusion

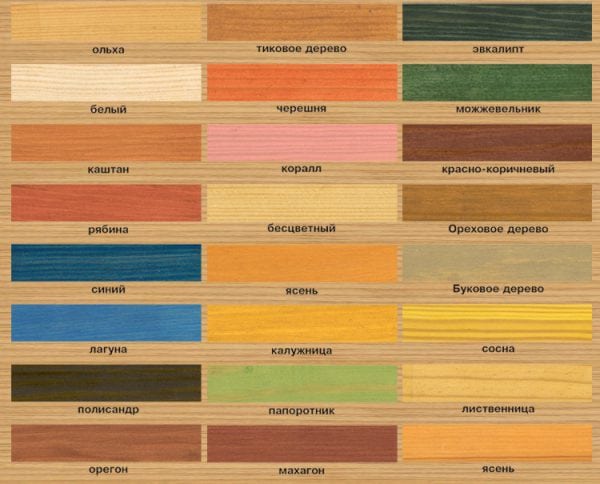

The color change is achieved due to the pigments contained in the impregnating compositions. It is also worth noting that impregnation, unlike paints, does not hide the natural texture of wood and does not form a film that is noticeable upon tactile contact. If desired, you can give the tree a glossy look or make the surface matte.

Talking about compounds designed to improve the appearance of wood, it would be wrong to keep silent about fire-retardants. They are used in combination with decorative and protective compounds. You should also know that decorative impregnations themselves perform protective functions. In particular, such compositions prevent darkening of the material on facades or in arbors (due to the influence of precipitation), as well as in the interior of the premises (for example, due to humidity in the baths). In addition, impregnations protect the tree from the negative effects of ultraviolet radiation, fungal mold, harmful insects.

to contents ↑Enemies of wood

Factors that cause harm to wood are listed in the table below.

| Factor | Description of the problem |

|---|---|

| High humidity | This includes atmospheric precipitation and soil dampness. Dampness occurs due to precipitation, too damp soil, and also in humid rooms. If the material is porous, humidity is a dangerous factor that can lead to unpleasant consequences, including: Moisture accumulation inside the material. As a result, the tree swells and deforms. Structural changes in the material can result in cracks or even destruction of structural elements of the building. Mold fungus that occurs at high humidity spoils the appearance of the product, destroys the structure of the material, and is a source of unpleasant odor. The spores of the fungus are in the air. Once on the surface of the wood, they penetrate the material within 4-5 hours. Some varieties of the fungus are particularly aggressive. For example, a white mushroom home is capable of rendering a 40 mm board worthless in 3-4 weeks. Also, one should not forget about the negative effect of fungal spores on human health. The process is the destruction of cellulose. Ultimately, decay leads to the destruction of material and the unsuitability of the house for living. |

| Harmful insects | Another enemy of wooden products is pests. They feed on wood. Also rodents spoil the material, penetrating into the house for eating the edible stocks of residents. |

| Fire | Wood is a fire hazardous (flammable) material. |

| Wind and Sun Rays | Unlike moisture, the wind and the sun's rays dry the material, which leads to cracking and fading. |

The mechanism of action of impregnation

The impregnating composition forms a strong protective layer on the surface of the material. The layer prevents the influence of humidity, the effects of ultraviolet rays. The structure of the material becomes much stronger. In this case, the coating gets a beautiful silky sheen. Impregnating solution is valid for 5-10 years.

Some parts of the building are exposed to particularly severe environmental stresses. We are talking about such structural elements as:

- lower harness in contact with the foundation;

- logs on which the floor is laid;

- basement and basement elements.

Wooden products related to the first and second points, there is no need to process decorative compositions. However, the basement and basement are often equipped with wooden products, which I want to give a more aesthetic appearance.

In parts of the house located below ground level, there is the impact of several negative factors at once, including soil moisture, precipitation, and biological elements. In this regard, for structures subject to increased wear, special compositions are used - indelible and water-soluble. Such impregnations are usually not used in combination with decorative ones, since they change the color of wood to dark green.

to contents ↑Fire protection

Decorative protective impregnations are used in conjunction with fire fighting compounds. Such compounds penetrate the structure of the material and protect the tree from fire.

In addition to impregnation, other surface treatments can be used, for example, special protective paints and varnishes. However, paints and varnishes change the natural color of wood, which is far from always acceptable.

to contents ↑Note! When buying fire-fighting compounds, it is necessary to ask the seller about the availability of quality certificates, as well as about the possibility of using one or another impregnation inside the building.

Decorative impregnation

Compounds to improve the appearance of wood are used after treatment with fire fighting compounds. The choice of color imparted by impregnation depends on the preferences of the designer or the tastes of the residents of the house. However, it should be noted: when it comes to the facade of the building or other structures located on the street, it is not recommended to opt for light or transparent compositions. The fact is that such impregnations are subject to the negative influence of ultraviolet rays. The consequence of this effect will be darkening of the material. Therefore, it is recommended to use bright or dark colors for outdoor work.

Classification of impregnations by composition

Based on the impregnation, the compositions are divided into two varieties: water and organic. The table below shows the main characteristics of these impregnations.

| Variety of the basics | Advantages | disadvantages |

|---|---|---|

| Water |

|

|

| Organic |

|

|

In addition to the base, the composition of the impregnation may include such components:

- flame retardants (interfere with burning);

- fungicides (prevent the development of fungus and mold);

- hydrophobic substances (increase resistance to moisture);

- metal salts (inhibit the effect of ultraviolet radiation on wood);

- pigments (provide a decorative function of the composition).

Impregnation characteristics using the Galamix example

As an example of decorative impregnation with protective properties, one can cite a composition such as Galamix-57. Impregnation refers to acrylic based water dispersible compositions.

The main advantages of "Galamix-57":

- Full environmental safety of the product, since toxins are not used in its production, moreover, they emit unpleasant odors.

- Harmless to the human body, which means the possibility of use not only outside the building, but also for internal work.

- Product components provide coating resistance to aggressive environmental factors for a decade.

- Both colorless and colored formulations are offered.

Material consumption

Galamix is economical in consumption: from 100 to 120 grams per square meter. To calculate the required amount of material, it is necessary to multiply the specified flow rate by the total area of the room. It is recommended that you take a margin of 10-15% of the estimated.

The stock is necessary based on several factors, including:

- application method (if a spray is used, the flow rate will be higher);

- technological costs;

- porosity level of the material.

Surface preparation

Impregnation treatment with Galamix is not very difficult, however, in order to ensure the manufacturer's stated stability and service life, it is necessary to fully comply with technological requirements. First of all, we are talking about preparatory measures.

Before impregnating the surface, you must perform the following steps:

- Remove dust, debris and other contaminants from the surface.

- If there are old coatings, they must be removed.

- It is also necessary to remove the darkened places, because if this is not done, then in the case of transparent impregnation, the darkening will remain visible.

- Remove all smudges and stains.

Surface grinding also improves the adhesive qualities of the material. The adhesion level expresses the ability of one material to adhere to another. For grinding, the grinding surface with 120-micrometer grain is considered optimal. Grinding is recommended using a grinder.

to contents ↑Impregnation

Impregnation of wood can be carried out using various tools. It’s more convenient to handle hard-to-reach places and joints with a brush. The roller is more suitable for large surfaces - a large area can be processed with one movement of this tool. Spray gun is recommended for use on large areas (for example, when impregnating the facade of a building). Using a sprayer allows you to get the maximum quality of the coating, as well as uniform distribution of the material.

When applying impregnation, it is recommended to adhere to the following rules:

- The coating is applied parallel to the wood fibers.

- If the wood is loose, its fibers can rise when wet. To avoid this, it is necessary to grind after drying the material. Grinding is carried out using fine-grained sandpaper (grain size - from 240 to 320 micrometers). After grinding, you need to apply another layer of impregnating composition. Sometimes you may need a third layer.

- The approximate time for drying the surface after applying each layer is from an hour to two. Finally, the surface dries after about a day after treatment.

Conclusion

Thus, decorative impregnations cannot be considered separately from their protective functions. Therefore, when choosing an impregnating composition, it is recommended first to pay attention to its ability to protect the tree from adverse environmental factors. If the impregnation meets these basic characteristics, you can give preference to one or another tonality of the composition - depending on your taste or the advice of the designer.