Wood is an excellent building and decoration material, because it is beautiful, environmentally friendly and durable, but everyone knows about its drawback: increased sensitivity to moisture. Upon contact with the liquid, the fibers swell and lose their shape, which significantly reduces the service life. To prevent this, mastic for wood helps.

- Why do I need mastic

- Composition and main characteristics

- Advantages and disadvantages

- Mastic classification

- Separation of technological features

- Separation by composition

- Features of hot solutions

- Rules for applying mastic to wood

- How to apply this material on a wood surface

- Create your own mastic

We are talking about a special composition, which is made both from natural components (beeswax, oils), and from chemical (bitumen, rubber, white spirit, turpentine, gasoline).

to contents ↑Why do I need mastic

When used correctly, these compounds help protect wood from swelling and deformation and create a reliable protective layer that:

- preserves the natural color and makes it brighter;

- emphasizes the natural fiber pattern;

- reliably protects a wooden surface from dust and moisture.

Mastic saturates the wood with protective substances, making it resistant to moisture and giving it antiseptic properties. Wooden log houses treated with special mastic perfectly tolerate wintering, without fear of frost or snowfall. These compounds protect the fibers, and regular processing helps to increase the service life of buildings for many years.

to contents ↑Composition and main characteristics

Mastic for wood is prepared from a variety of components and can be different. But in general, mastics have one common property: excellent waterproofing. If their composition includes natural components, then the protective layer can stretch, exceeding the original area by more than 20 times, but without creeping and not being deformed.

Some formulations do not harden completely even many months after application. They have excellent adhesion: they fit well on a wooden surface and do not leave it for a long time.

Mastic allows you to create a water-repellent layer, provides resistance to dust, ultraviolet and various pollution. The main advantage over conventional varnish is that it penetrates deep into the fibers and extends their service life, and does not remain on the surface, as conventional formulations.

Advantages and disadvantages

If you want to combine all the advantages of mastic for a tree and bring them to a common list, then it will look like this:

- Environmental friendliness. Here you need to consider the composition of the substance.

- Durability. With regular care, wooden products can last dozens or even hundreds of years.

- Elasticity. She stretches well.

- Simple application. Mastic can be used by a person who does not have much experience in repair or construction.

- Heavy duty protection. Wooden floors crack less and retain their structure.

- Enhancing aesthetics. Mastic gives wood a pleasant shine, makes its color more saturated and noble.

The disadvantage is that it is necessary to update the coverage 1-2 times a year. In addition, individual formulations contain corrosive chemicals, including gasoline and solvents, which, when dried, evaporate and rise into the air. This is directly related to cold curing mastic. If you used this, you must work in a protective mask, as well as withstand several days and ventilate the room well before checking in.

to contents ↑Mastic classification

It is worth considering in more detail the question of what kind of mastic can be found on sale and for what purposes is it intended. This useful help will help you make your choice.

Separation of technological features

According to this factor, mastic for wood is divided into 2 types:

- cold

- hot.

The first contains gasoline, solvents and white spirit. When dried, these fumes can be harmful to health. The second is made of bitumen and rubber, and therefore is considered more environmentally friendly. It dries much faster.

to contents ↑Separation by composition

The tool can be manufactured not only from those components that were given above. For example, hard mastic for polishing the floor is made on the basis of beeswax, while it is effective and durable.

If you process floors that were previously laid on bituminous mastic (for waterproofing), then you can not use products that include turpentine. In this case, it is better to consult with a specialist.

Also mastics are:

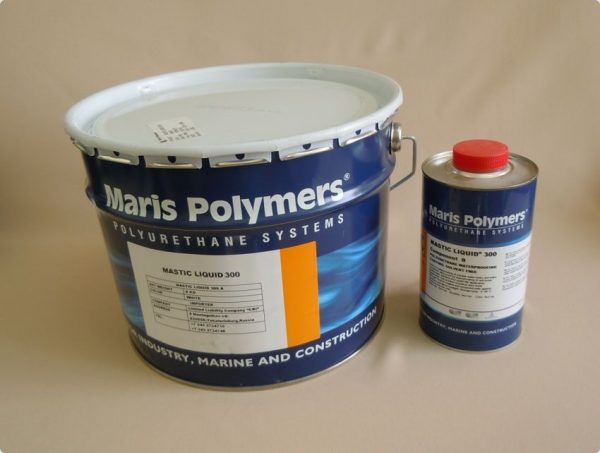

- unicomponent - are intended for single use as they quickly harden;

- two-component - more suitable for reusable use, but first they need to be mixed with a special thickener.

Features of hot solutions

They have deep penetration and durability. Such mastic can protect wood even from moist soil and constant humidity, and therefore it is used for processing basement floors, pillars and sex lags.

For application, such a mastic must be heated to a temperature of about 180 degrees Celsius. The process of using hot formulations is associated with a health risk, as severe burns can occur.

Rules for applying mastic to wood

You need to work strictly with gloves. This is a viscous substance that does not spray even in a liquid state, but it is recommended to use safety glasses and a mask when working with hot formulations.

to contents ↑The surface of the wood itself must be cleaned of dust and contaminants and dried well. If there is a layer of old varnish, it must be completely removed, otherwise the mastic simply will not be able to penetrate the wood fibers.

How to apply this material on a wood surface

To apply the mastic, you can use:

- brush with rough bristles;

- ordinary paint roller;

- spray gun.

In view of profitability and availability, it is recommended to use a roller and brushes. They do not require special practice and are cheap, so you can always buy new tools in any construction or hardware store.

to contents ↑Create your own mastic

If you do not want to use ready-made mastic for one reason or another, you can do it yourself. This will require the following components:

- wax (carnauba or bee) - 4 mass fractions;

- rosin (pine or gum) - 1 wt. share;

- turpentine (gum) - 2 wt. share.

Strictly observe the indicated proportions. First you need to grate the wax on a grater and mix it with crushed rosin. Then this mixture is melted in a water bath (you need to stir it systematically).

Further the most dangerous. Turpentine is very flammable. It must be heated in a container with hot water and excluded from an open flame. Heated turpentine is added to the prepared mixture of wax and rosin and mixed well.

At the last stage, the resulting mass is poured into a container. It cools and thickens, after which it can be used for application on wooden surfaces.

Using mastic, you can not worry about the condition of the wood: the coatings will be protected from scuffs, dirt and the appearance of unwanted microorganisms.