For wood processing, various types of tools are used. Many of them, in particular, varnish and paint, are used to create a protective and decorative coating, but give the tree an unnatural glossy background or completely cover the natural woody pattern.

- What is the stain for?

- Difference of stains from drying oil, paint, varnish

- Types of stains

- Water stain

- Alcohol and nitromethyl

- Oil stain

- Acrylic stain

- Wax stain

- Rustic stains

- Color spectrum

- Popular manufacturers

- Technology of work

- Surface preparation

- Surface stain application

- Drawing a stain on a stain

- Stain for varnish or paint

- Consumption and drying time

- Defect Management

- How to wash stain

- How to varnish wood after stain

A wood stain gives a completely different result: it not only protects the material from spoilage, decay, but also enhances its natural beauty and can even “turn” an inexpensive breed into an elite one.

to contents ↑What is the stain for?

In a professional environment, wood stain is called a “stain”. This liquid tool allows you to give the desired color to the wood without changing its texture, pattern. On the contrary, stains emphasize the whole aesthetics of natural wood, reinforcing it, ennoble simple species: after processing, even from pine, you can "make" dark oak or other expensive varieties of material.

Any wooden products, despite their durability, are subject to various adverse factors. Using a stain, you can protect the wood from damage by putrefactive fungi. There are different types of stains, the properties of which depend on the composition.

The main qualities of beits:

- tree protection against ultraviolet radiation;

- the destruction of woodworkers and other pests;

- increased surface service life;

- wood lightening;

- moisture protective function;

- the possibility of restoration of old products;

- compaction of the structure of the material;

- preparation of wood for further processing - painting, applying varnish.

Some stains should be used only indoors - to cover floors, countertops, furniture, interior doors. Others are suitable for outdoor use - for example, for processing floors on an open veranda. Some products are used only on the surface layers of wood, others are distinguished by the possibility of deep penetration. Many modern stains can not only be applied to the base, but also carry out various interesting effects - combine tones, create shades uncharacteristic for the tree.

to contents ↑Difference of stains from drying oil, paint, varnish

Wood stain is called a wood stain. It penetrates deeper, inside the tree tones, not closing its natural pores and preserving the pattern, while protecting it from decay and destruction. Drying oil also protects the material from moisture and putrefactive processes, but after its application a film appears on the surface.

Drying oil is weakly embedded in the deep pores of the tree, but it clogs them outside. If the stain can become an independent means for decoration, then drying oil is used only to prepare wood for further work to improve the quality of staining and reduce the amount of paint.

Varnish is also very different from stain-impregnation. Varnish is a film-forming agent, and a protective film from it is formed after evaporation of the solvent from the surface. Oil varnishes form a heavy-duty elastic film, which is difficult to wipe even with white spirit. Again, the varnish layer will have to be updated over time, having previously removed the previous one. Typically, varnishes are used where there is a strong influence of atmospheric factors, and the stain will have to be applied too often.

Paint is another popular finishing material for wood. You can paint absolutely any wood products: from the floor to window sills or furniture. After staining, a dense, opaque film forms on the surface, which completely hides the natural woody pattern - this is a cardinal difference from the stain. Typically, the color gamut of paints is far from natural: white, black, brown, green paints are more often sold. After 2-3 years, many types of paints lose their strength, snap off, after which you will have to completely remove the old layer and apply a new one.

to contents ↑Types of stains

There are various types of beits on sale, which vary greatly in base, additional composition and properties. At home, you can use any of them, but the application procedure, drying time are not always the same.

Water stain

Water-based stains are the most inexpensive and popular. They are implemented in finished form or are dry (powder): the latter must be diluted with water before work. The range of shades of water stains is diverse, but includes only natural woody tones. The use of such tools is necessary for tinting wood or enhancing the natural color, giving expressiveness to the structure.

Usually, a water stain dries for 10-14 hours, because the formation of a coating requires complete evaporation of moisture. Penetration into the structure of the tree will be deep, therefore, protection against decay - more reliable. But the moisture resistance of the wood will not increase, therefore, such stains should not be used for street surfaces.

Other properties of water-based products:

- concealment of fiber defects;

- lack of an unpleasant smell;

- environmental friendliness, suitability even for children's rooms, furniture;

- the ability to wash off the stain until it dries completely;

- ease of shade change in the future.

to contents ↑Usually, after water stains, it is recommended to treat the base with colorless varnish: this will enhance protection against adverse effects. Due to the deep penetration into the structure of the tree in some species, individual fibers may rise to the surface, and the product will have to be additionally sanded.

Alcohol and nitromethyl

The non-aqueous stain contains alcohol or an organic solvent. The last type of base is present if the name of the product is marked “nitro”. As a coloring matter, aniline dyes are included in such agents. For work, you can buy ready-made stain or powder, a liquid concentrate for dilution with alcohol, white spirit.

Coating wood with an alcohol stain is easy, it does not take much time to dry, 5-30 minutes are enough. Due to the high drying speed, it is not recommended to apply the product manually: for this purpose it is better to purchase a spray gun. To dilute the thickened stain, just drop a little solvent. Alcohol stains give excellent protection against moisture, ultraviolet radiation, therefore they can be used on surfaces operated outdoors. The disadvantage of nitromorilok is its high toxicity, which is why it is better to work with them only in air.

to contents ↑Oil stain

The composition of oil products contains special synthetic or natural oils, soluble dyes in varnish. You can breed them with both drying oil and white spirit. They have a lot of positive qualities:

- environmental friendliness of the composition;

- lack of unpleasant smell and harmful impurities;

- deep impregnation of wood;

- lasting color for many years;

- giving a high level of moisture resistance.

Most often, oil stains protect the surface of furniture, a wooden floor, and parquet. For outdoor work, they are also suitable, because they do not fade from the action of sunlight. It is very convenient to apply the funds, even a novice can do this correctly, and with any painting tool. Drying time for oil stains is significant (up to 10-48 hours), which must be planned before starting work. For further processing, the base will be ready only after complete drying.

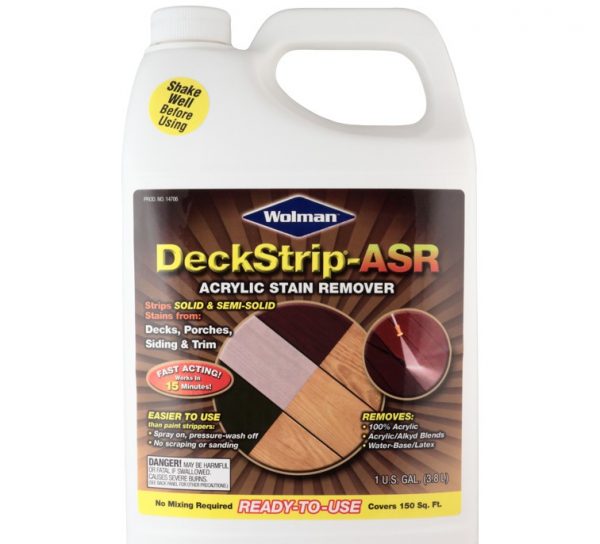

to contents ↑Acrylic stain

This type of beits is the most modern, therefore their quality is excellent, although the price is high. Acrylic stains are made in liquid form, they have a rich palette of shades, both woody and unusual, bright or light. Such compositions have many advantages:

- safety for humans, animals, the environment;

- quick drying;

- lack of smell;

- easy application, no stains, smudges and stains;

- perfect evenness of the finished coating;

- reliable protection of a tree against moisture, decay, UV rays.

Wax stain

Wax-based fighters are on sale recently. These non-aqueous compositions have a slightly different principle of action: they do not penetrate deep into the tree, but, like varnish, create a film on the surface. The protection of wood after waxing is so powerful that it is recommended to use it to cover a bathhouse, a steam room, any street buildings: water will literally roll down from surfaces. You can also use wax stains as a basis for further painting, varnishing: after them, the paint and varnish materials lie perfectly evenly, without spots.

to contents ↑Rustic stains

This is another type of stain that belongs to the latest generation of wood structure enhancers. Most often, rustic stays are used by professionals for arranging parquet. Without experience, it will be difficult to achieve a beautiful and high-quality result. Masters using these tools make unusual effects, elegant color transitions. Rustic stains are especially recommended for work on a natural oak board.

to contents ↑Color spectrum

Beitz is a unique tool that helps give wood a noble hue. The structure of the wood is heterogeneous, different areas are impregnated unevenly, so after the composition has dried, an original pattern is created on the surface. The most popular shades of wood stains are included in the wood gamut, their names correspond to different types of wood. Also on sale there are other types of stains: green, black, red, blue and corresponding to other tones, which are usually used for coloring furniture. If choosing the right color does not work, stains of the same type and brand can be mixed together.

When buying, you should carefully consider the samples on which the stains are applied, because on the label and in reality the shade may not match. The finished color will depend on such factors:

- initial shade of wood;

- the degree of porosity of the material;

- density;

- breed;

- amount of resin.

Popular manufacturers

Today, the market has a large number of stains of different manufacturers. It is difficult to choose the best: many products have excellent quality and have a reasonable price. You can buy stains in any hardware store: Ikea, Maxidom, Leroy Merlin and others. The selection of a good stinger for woodwork can be done from the following list:

- "Novbytkhim" (NBH). An odorless, water-based stain that forms an abrasion resistant coating. Helps to tint doors, skirting boards, railings, platbands, planks and other products.Has a rich palette of shades, can be used in decoupage.

- Coswick Wood Stain. Alcohol stain for tinting and protecting wooden substrates. Helps to repair small scratches, chips, to process ends when installing parquet. It goes well with varnishes.

- "Rainbow 21". Acrylic stain, contains special substances for protection against mold, wood-destroying fungi. It has a high degree of adhesion to all types of wood.

- Zar. Quick-drying composition for interior and exterior use, with a self-leveling structure. It is applied to wood without stains, stains.

- Tikkurila Pirtti (Tikkurila Pirtti). Colorless stain, which is tinted according to the Tikkurila pigment catalog in absolutely any color: mocha, antique, villa and others (36 glazed shades).

- Liberon It is used for restoration and protection of wooden surfaces, suitable for work outdoors and indoors. The tool is resistant to UV radiation.

- Varathane ("Varatan"). Oil stain from transparent soybean oil, has pure natural shades, is distinguished by a deep penetration into the wood.

- Zerwood. Water-based stain has many colors, corresponding to noble varieties of wood.

- Minwax ("Minvax"). Impregnation in oil, giving beautiful shades to wood and protecting products from water, ultraviolet radiation.

- Pinotex Interior ("Pinotex Interior"). Water-based decorative impregnation is widely used for finishing works and protecting wood from external factors.

- "Krafor." The product is used on products used inside and outside buildings. The finished coating is perfectly polished, does not require varnish.

- "Biotex Universal". Antiseptic impregnation, gives off the structure of wood, gives a beautiful shade, prolongs the service life.

- "Vertex". A popular inexpensive stain on the water, has a wide range of shades: rosewood, ebony, beech, walnut and many others.

- Tury. Wood stain, attractively matte. It emphasizes the structure of wood, protects against microorganisms.

- Renner. A concentrated product with a highlighting effect, water-soluble, has 17 basic colors.

- "Latek." It is used to isolate wood fibers. It does not fade under the influence of light, is evenly applied, has a high moisture resistance.

- "Belinka." The azure coating for wood based on wax is intended for long-term protection of wood from any external factors.

- Herlac A range of eco-friendly stains without harmful components. Are applied to any joiner's products, a chipboard, lining, an interline interval.

Technology of work

The method of applying it depends on the type of stinger. Usually for painting use a brush, spray, swab, sponge. Non-smooth and large-sized bases are best treated with a spray gun (in the first case, the brush is not used so that there are no bristles left on the tree). To work with a sprayer, a lighter shade of stain is chosen: the layer will be thicker, which will make it appear darker.

Swabs and sponges are usually applied oily products. You can not buy, but make such a device yourself: wrap cotton wool with a cotton cloth or just cut off a piece of foam. Water and alcohol stains are applied with synthetic bristles. The quality of the tool must be high, otherwise it will "lose" the bristles.

Before the main stage of work, a test color is always produced to clarify the required number of layers to obtain the desired shade. The procedure is as follows:

- take a tablet of the same breed as the main material, sand it;

- impregnate the product;

- leave to dry;

- apply another layer to 2/3 of the plank;

- after drying, treat the third layer with another 1/3 of the workpiece;

- as the final drying out, evaluate the appearance of all three areas, select the optimal shade.

Surface preparation

Always apply impregnation only on a clean base. There is usually no problem with a new product. But sometimes it is necessary to process old wood, which was damaged during long operation, was varnished or stained.Before working with wood, it is necessary to remove the layer of old coatings. To erase the varnish, the paint can be with special washes. If this is difficult, mechanical or thermal effects will come to the rescue:

- The first way. Apply an organic solvent to the base, then go over it with a spatula, scraping off the paint.

- The second method (for a thick layer of paint). Moisten the surface thoroughly with a wash, cover with cellophane, remove it after 24 hours and treat the base with a knife, putty knife, grinder.

- The third way. Warm the product with a building hair dryer, then remove the paint with a spatula. You can use a blowtorch, but the wood must first be moistened with water.

The remaining coating is sanded with sandpaper. If there are cracks on the base, they must be repaired with putty on wood, after drying, sand the treated areas. All protruding knots should be cut, sticking out fibers should be eliminated with sandpaper. The raw tree needs to be allowed to dry well, otherwise the stain coating will not have the proper quality.

Softwood will have to be tarred before applying the stain. To do this, you need to prepare a special composition, apply it abundantly on wood, and after 30 minutes, rinse, dry. Here are the recipes for such formulations:

- 750 ml of water and 250 g of acetone;

- 1 liter of water and 50 g of caustic soda;

- 1 liter of water and 50 g of potassium carbonate, 60 g of soda ash.

Surface stain application

Before tinting wood, all non-machined surfaces must be covered with a film or glued to the edges with masking tape. The technique of wood treatment with wood stain is almost no different from ordinary painting. It is only important to act quickly so that the coating is more uniform. Do not put too much money on the brush, ugly streaks will remain.

Woodwork should always be parallel to the direction of the wood fibers. Pre-stain is bred to the desired consistency, if necessary. Here are other recommendations for tinting surfaces:

- you can not proceed to the processing of a new section without completely painting the previous one;

- at the junction of the two sections, it is important to ensure that the stain layers do not overlap each other;

- the most beautiful coating is obtained using the spray method: the risk of spots, unpainted areas is minimal;

- rubbing the oil stain with a rag gives the effect of an oak even on the cheapest material;

- the first layer is always made the thinnest, it will create the basis, reduce the consumption of material for subsequent layers;

- most often, 2-3 layers of stain are required to give the optimal color, and each of them is carefully dried.

After the water stain has dried, raised wood fibers inevitably appear on the surface. They need to be cleaned with coarse cloth in the longitudinal, diagonal direction.

to contents ↑Drawing a stain on a stain

If there is a desire to update the shade of the tree, you can purchase another stain and apply it on top of the previous one. It is only important that its tone is not lighter, otherwise the desired color will be difficult to achieve. Usually, only 1-2 coats of stain are required for repeated tinting.

Stain for varnish or paint

Since varnish, paint create a dense protective film on wood, the stain will not be able to penetrate the fibers, impregnate the material and highlight its structure. The product will simply dry on a layer of varnish or paint, staining the surface. First you need to completely remove the previous coating and only then apply a stain.

to contents ↑Consumption and drying time

Consumption per 1 m2 depends on the type of stain, as well as on the quality of the preparation of wood, the method of application. So, for an acrylic stain, this figure is about 120 g / sq. m, for oil - up to 150 g, for water and alcohol - from 50-70 g.Drying time also depends on the type of stain. Water and oil coatings dry 10-14 hours, alcohol dries almost instantly, acrylic - in 60 minutes, wax - in 10-15 hours. For oil coatings, the time before the start of operation should be at least 2-4 days.

to contents ↑Defect Management

It happens that the stain lay on the surface incorrectly. Here are the main ways to fix defects:

- With sagging. Immediately after tinting the tree, you need to cover the area with varnish, which will dissolve the stain. Then use a rag to clean the treated area. When the drip has already dried up, it will have to be softened with white spirit or grinded with sandpaper.

- With spots. If we are talking about plywood, you have to remove the entire veneer with a planer. Array is also treated with this tool, removing a thin top layer.

How to wash stain

The easiest way to wash it with your hands or with treated wood is a water stain. Of course, only the top layer will be removed, because such stainers are distinguished by deep penetration. Soiled clothes can be washed with ordinary powder, then rinse with air conditioning. If necessary, oxygen bleaches are used, and chlorine is used on white things.

to contents ↑If the stain got on linoleum, the stain is rubbed with acetone, white spirit. Work must be done carefully so as not to discolor the surface of the material. It is possible to get rid of stains on the skin with vegetable oil or as a result of frequent hand washing with soap. Removing non-aqueous types of wood stains from surfaces is much more difficult, you will have to remove the top layer of wood along with the tint coating.

How to varnish wood after stain

Usually, varnish is applied over the stain to enhance the wear resistance and appearance of the product. In order not to spoil the coating, it is important to follow the rule: combine alcohol stains only with non-alcohol varnishes, apply exclusively non-aqueous varnishes on water stains. In this case, the paint and varnish material will lie evenly, will not break, and the quality of work will be at the highest level.