Logs are one of the most important components of floors in a home. According to their purpose, these are supporting elements on which floor boards are laid. Thanks to the lags, the rigidity of the entire floor structure is ensured. Therefore, it is important to ensure their resistance to rot and microorganisms. It is possible to achieve moisture resistance by special processing of wood. About how and how to process the lags will be discussed below.

- Lags and the environment

- Classification of compounds for processing lag

- Branded compounds

- Fire retardant substances

- Bioprotective compounds

- Leachable antiseptics

- Folk remedies

Lags and the environment

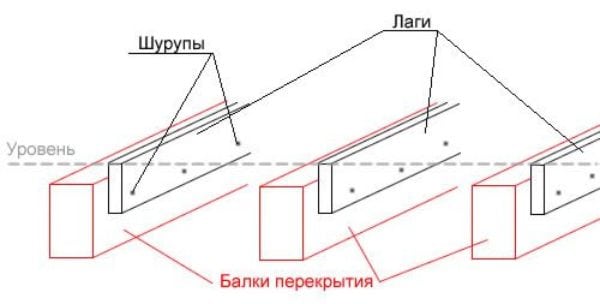

Theoretically, logs should not be directly affected by aggressive environmental factors. First of all, we are talking about dampness. The fact is, if the lags are laid on the foundation of the building, they do not directly contact with the environment, since the material is vapor-insulated and waterproofed. However, in the subfield, due to temperature differences between the upper and lower levels, condensate still accumulates.

It should be understood that builders do not always strictly observe the technological process when laying floors, and if this was so, then the wooden structure will also begin to rot.

Another enemy of wood is harmful microorganisms. Due to natural factors, any unprotected wooden structure is susceptible to pests. Therefore, the processing of any wooden structures is an urgent need.

There is no one - the only true way to handle lags. In each case, you need to consider many circumstances, for example, the type of tree. After all, each kind of wood reacts in its own way to humidity. Nevertheless, it is possible to give a number of general recommendations that will allow you to get an idea of the correct approach to the processing of lag floors.

to contents ↑The main way to protect wood from rot and microorganisms is through chemical treatment.

Classification of compounds for processing lag

Chemical products for protecting wood during floor installation, according to building codes and rules, are divided into several types:

- superficial antiseptic agents;

- impregnation;

- film-forming compounds.

According to the norms of SNiP, surface compositions are divided into three types:

- water soluble;

- organic

- oil.

Fluorides, borates (leachable antiseptic substances), as well as complex compounds containing chromium, arsenic and copper (difficultly leachable antiseptics) are classified as water-soluble compounds. Organics include compounds based on alkyds, urethanes and acrylics. A large group of oil compositions include substances based on coal, anthracene and other compounds of this kind. Also to oil preparations include compositions based on vegetable oil, tar, rosin.

Glazing compositions are used for surface treatment. Surface application refers to a depth of 1-3 millimeters.Impregnations are able to penetrate the structure of a tree by 15-35 millimeters.

Note! Leave-in products are used to protect parts subject to heavy rainfall and regular wet cleaning.

According to the functionality, antiseptic agents are classified as follows:

- preserving;

- fireproof;

- transport;

- whitening.

Chemicals can be conditionally divided into compositions of factory production and folk remedies.

to contents ↑Branded compounds

They are divided into fire-protective and bioprotective agents, as well as indelible antiseptics.

Fire retardant substances

This method of protection is among the most effective, since it allows you to protect wooden materials not only from microorganisms, putrefactive processes, but also protects from fire. The latter quality, due to the fire hazard of wood, is of considerable importance.

Fire-retardant substances preserve the lag structure for many years: fire protection is provided for 3 years, and biological material protection - for 25 years. Although if the wood product is not used in extreme conditions, the real life of the drugs will be higher.

Fire-retardant compounds are environmentally friendly, no unpleasant odors and complete safety in use. The environmentally friendly preparations are ensured by their composition: there are no components hazardous to humans, including allergens.

Any legally sold drug must have a certificate of the sanitary-epidemiological station, fire regulations and a quality certificate.

to contents ↑Bioprotective compounds

Preparations of this group improve only bioprotective qualities of wooden materials. Bioprotective compounds protect wood from blueness, mold, rotting, destroying the material of fungi and woodworm beetles. The drugs provide biosecurity for 25-30 years.

Most often, antiseptic drugs are sold in the form of concentrates. In some cases, pigmenting agents are added to the formulations. The pigment allows you to visually check the quality of the coating on a wooden surface.

Bioprotective agents are distinguished by a slight smell, environmental friendliness, and do not contain allergens. They are easy to prepare - just dilute in water. Surface treatment can be carried out in various ways, including roller, brush, spray gun, dipping.

to contents ↑Leachable antiseptics

They are used to protect structures operating in conditions of high humidity. For example, indelible antiseptics are relevant for high rainfall, temperature differences, as well as in buildings where the tree is often moistened under operating conditions (baths, saunas).

Working with indelible antiseptics is not difficult, but it takes a lot of time. The approximate consumption of a substance per square meter is 350-400 grams. Surface application is achieved after 3-4 layers. If we are talking about dipping, you will need to withstand the material for 20-30 minutes.

This group of antiseptics gains adhesive qualities after final drying. The color of the wood usually becomes pistachio, thanks to the pigments added to the composition.

to contents ↑Folk remedies

Wooden floor logs can be processed not only with factory compounds, but also with all kinds of folk remedies.

- Transformer oil. When processing a log with this chemical, oil penetrates deeply into the wood structure and embalms it. There is no scientifically based evidence of the effectiveness of the method, but judging by the reviews of the masters, transformer oil really helps protect the wood.

- Engine oil. It is often used to protect lag and used engine oil.There is a significant drawback in its use - mining has a very unpleasant and persistent smell. Moreover, the smell can persist for many years - until complete weathering. Therefore, mining can be used far from everywhere: in technical premises, but not in residential buildings. The advantage of this technique is the low cost or even the free cost of used oil.

- Resin. Compositions based on resin, for example, resin of coniferous trees or birch tar protect wood from rot, fungus, and pest beetles. The main disadvantage of resinous compounds is their vulnerability to fire hazard. In addition, the resins are characterized by a persistent, difficult to weathering odor.

- Brine. According to some masters, salt can protect wooden logs. To make the solution, you need 100 grams of salt per liter of water.

When choosing a specific composition for protecting the lag, one should be guided by the goals set. Of all the options described above, the ideal choice is a fire-retardant substance that has a maximum spectrum of action.