A bathhouse is a structure that is subjected to increased loads during the entire period of its operation, first of all, it is a question of high humidity and sharp temperature drops. All this has a negative effect on the wood from which the bath is built. In addition, wood itself is sensitive to the environment. For example, a tree is deformed under the influence of seasonal changes in temperature conditions. Thus, to extend the operational life of the wood needs to be protected. About how to process the log house baths will be discussed in this article.

- Means for protecting the log house

- Classification of protective equipment

- Processing a bathhouse

- Processing the log house from the inside

- Information on choosing a tree for a log house

- Folk remedies

Means for protecting the log house

It is possible to protect wood from negative influences with the help of special impregnations of universal and multidirectional action.

Types of wood impregnation:

- Antiseptic agents. Designed to protect wood from the harmful effects of fungus and pests. The mechanism for preventing excessive moisture is based on the deep penetration of impregnation into the structure of the material. After the impregnating composition penetrates deep into the wood, clogging of the pores occurs. Thus, the penetration of moisture into the material in the future is blocked.

- Wood is known to be a flammable material. To protect against ignition, special substances are produced - flame retardants. Such impregnations are used both inside buildings and outside.

- Complex formulations. They have a universal purpose. They simultaneously perform several functions, including protecting the tree from mold, rot, harmful insects, as well as fire.

Classification of protective equipment

For the proper selection of an antiseptic drug, it is important to have an idea of their types.

There are several types of antiseptics:

- Easily washable. Such impregnations contain metal salts, which are gradually washed out under the influence of moisture. Such impregnations are best suited for dressing rooms, rest rooms, but not for steam rooms.

- Difficult to wash. These impregnations contain natural and synthetic oils. Suitable for external processing of log cabins.

- Brief action. Such impregnations are quickly absorbed and are best suited to high humidity and high temperatures. In addition to mold, short-acting impregnations protect against rot and bark beetles.

Part of the impregnation is available in a colorless version, however, most compositions contain pigments that give the material a specified shade. The use of bright impregnations facilitates the work, as the treated areas become noticeable and there is less chance of missing some area.

The advantage of colorless antiseptics is the preservation of the natural color of the tree. At the same time, it is recommended to work on such wood with a brush and not with a sprayer, since in this case it is easier to control the areas of work done.

to contents ↑Processing a bathhouse

The standard method of impregnation with an antiseptic involves working with a brush or spray. It’s harder and harder to work with a brush. However, it is indispensable in some cases, for example, when a place cannot be qualitatively coated from a spray gun. Every 2-3 hours, it is recommended to change the brush to a new one.

Spray impregnation is considered to be of better quality and, most definitely, is carried out much faster.

Advice! Impregnation of wood is recommended even before the log house is folded with crowns. Only in this way can a thorough study of the entire surface be ensured.

In some cases, alternative methods of processing wooden structures are advisable:

- The method of immersing wood in a container with an antiseptic. This approach guarantees the impregnation of even the most inaccessible areas of the structure.

- The diffuse (dry) method of treatment with an antiseptic preparation is the application of a paste or powder substance to the surface.

Before you begin to impregnate the log house, it must be cleaned of all kinds of clogs. A vacuum cleaner is suitable for this purpose. Then the surface must be well dried.

The compositions are applied in the following sequence:

- means for protection against fungus and moisture;

- impregnation from insect pests;

- fire fighting agent (fire retardant).

Note! All wooden surfaces must be treated, not just those that are most exposed to moisture.

At the end of surface treatment with antiseptics, it is recommended to apply a gel or primer. However, we must not forget about the basic rule: the material must be breathable.

If everything is done in accordance with the technology, then subsequent impregnations are done no earlier than three years later. Some formulations last up to five years.

to contents ↑Processing the log house from the inside

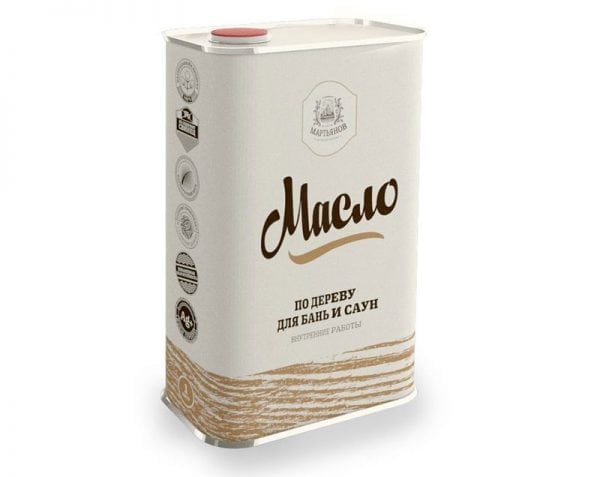

With prolonged and regular exposure to steam, moisture, which involves the operation of the baths, the functionality and appearance of wood can suffer. Without the use of special protective equipment, the service life of the log house is reduced. Best of all, special oils for baths and saunas protect the tree from the harmful effects. These are products based on natural ingredients - vegetable fats, wax, lecithin, safe desiccants, without toxic compounds.

Oils are absorbed into the wood structure, strengthening it, protecting it from steam and water. As a result, the surface does not allow moisture to pass through, repels grease, dirt, and becomes resistant to detergents. Oils have antiseptic and fungicidal properties, so mold and fungus will not settle on the material. Some brands, such as Martyanov, also include wood blueing additives.

The advantages of oil mixtures are obvious:

- suitability for any kind of tree;

- protection even from extreme temperatures;

- improving the appearance, emphasizing the woody pattern;

- penetration into hard to reach places.

It is recommended to process bathhouse and sauna logs with oil every 5 years, which will preserve the properties of wood for many years.

to contents ↑Information on choosing a tree for a log house

When choosing an impregnation or paint composition, it is necessary to take into account the wood species from which the bath is built. Some breeds do not need additional moisture protection. These species include oak and most conifers. However, each breed has its own characteristics:

- Pine does not like heat and humidity, therefore, is not suitable for log cabins.

- Spruce is better to use in the dressing room, because, despite its excellent thermal insulation properties, this tree is even more afraid of moisture than pine.

- Aspen well tolerates moisture, but gives off the smell of bitterness.

- Birch loves dryness, and therefore is suitable only for dressing rooms.

- Cedar, larch are not afraid of moisture, but too resinous.

- Alder is great for making a log house.

- Oak and ash are used to decorate expensive baths.

The resin of trees suitable for making log cabins contains resins that contain volatile products. These substances are natural antiseptic agents. Thus, nature itself protects such wood from fungus, rot and insect pests.

However, excessive resinity (as in some coniferous species) cannot be attributed to positive qualities. The fact is that under the influence of high temperatures, the resin transforms into a liquid state and begins to spread.Of all coniferous species, only spruce most closely meets the requirements for a steam room.

to contents ↑Note! Whatever wood the bathhouse is made of, it cannot be heated before impregnation.

Folk remedies

If at hand there is no professional tool for processing the log house, you can use the tried and tested folk methods. Among the most famous folk remedies is copper sulfate (copper sulfate). Vitriol is affordable and effective. However, copper sulfate is not recommended for indoor use due to its toxicity.

Processing of the log house with copper sulfate is performed using the following tool:

- brushes;

- stiff bristle brushes;

- rubber gloves, tight clothing, a respirator or gas mask.

The application of vitriol is carried out as follows:

- The cleaned surface is thoroughly dried.

- Vitriol is applied to a wooden surface and rubbed well into it.

- After drying the material, you need to apply another 1 to 4 layers of copper sulfate.

Every few years, you need to re-impregnate the wood. Protected wood is not afraid of high humidity, rot, mold and pests. It is only necessary to take responsibility for work, not to spare time, effort and expense. Then the bathhouse will serve for many decades.