Wooden buildings without additional protection can not boast of significant durability. Traces of decay can appear on them quite quickly, so you have to apply various technologies against the development of mold, microbes. Many of them are not environmentally friendly, and such wood is used only outdoors. Wood firing is an absolutely safe method that was invented many years ago. It allows you to permanently preserve the natural qualities of the material and give it an unusual look.

- Timber firing technology: historical background

- Structural changes in wood due to firing

- Types of firing

- Advantages and disadvantages of lumber firing

- Firing at home - is it possible?

- Choice of wood species for firing and material requirements

- Preparation of material for firing

- Woodwork blowtorch

- Burning wood with a gas burner

- Does the burnt tree need extra protection?

- The choice of oil for wood

- The use of fired lumber

- The use of burnt wood in interiors

- Creating facades from a burnt board

Timber firing technology: historical background

Burnt wood has long been popular in a number of countries, while in others it is only beginning to become fashionable. Japan is considered the birthplace of the technique, where the so-called cedar sting was used: they burned the tree on bonfires, then they removed the soot, washed and applied tung oil. This allowed to give the material shine, a noble silver-black shade and increase the service life of up to 80 years. The history of technology dates back to the beginning of the 15th century, when, when burning cedar plantations for fire-fighting purposes, the unique properties of the resulting wood were accidentally noted.

On the island of Naosami in Japan and now a burnt tree is widely used for the construction of various objects, and is also widely used for interior decoration. The technique has long been known in Europe and America, where it was practiced along with laminating - impregnating lumber with hot resin. If earlier wood billets were burned with an open flame using torches, now special vacuum furnaces are used for this purpose.

to contents ↑Structural changes in wood due to firing

As the subcortical layers grow, new pores form in the wood. This causes the death of fibrous cells and leads to an increase in the porosity of the structure. The result is an invariable property of any wood - hygroscopicity, or the ability to absorb and give water when the humidity of the environment changes.

The tree has an uneven texture due to the presence in the composition of cellulosic polymers, resins, sugars and other organic components. Also, the material has high flammability, a tendency to multiply fungi and other microorganisms that constantly live inside and begin to multiply actively at the slightest dampness.

To reduce all the listed disadvantages of wood, while leaving it environmentally friendly, the technology of firing using autoclave heating (thermolysis) or creosote heating is capable of.

During the work, the material is heated to + 300 ... + 400 degrees, which allows you to destroy unstable hemicellulose formations.Since the latter are the cause of the appearance of combustible pyrolysis gases, their removal immediately reduces the flammability of the tree.

Wood firing at home has a less pronounced effect and removes fewer unstable compounds. However, this is sufficient to improve the operational properties of the material. Also, firing leads to partial clogging of the pores with resin and soot, narrowing of the channels in the outer layer of wood, so bacteria, sunlight, and moisture will practically not penetrate inside. After roasting, the loose tree also acquires fire-fighting properties, becomes immune to decay, and is less destroyed by rain and wind.

to contents ↑

Types of firing

The quality and appearance of the burned wood may vary depending on the particular technology that has been applied. The following types of firing are distinguished by the depth of exposure:

- Full. It is a burning of lumber at a temperature of about +400 degrees in a vacuum oven. Such wood is not in great demand, because its volume decreases by 2 times, and initially high strength characteristics decrease over time. Usually, a tree after complete firing goes to the manufacture of expensive furniture, decorative elements and other piece goods.

- Deep. A popular type of heat treatment of wood. It can be used in relation to new and used material, allows you to artificially age boards, to beautifully design a beam. During firing in open furnaces, the entire thickness of the lumber is uniformly heated, and the surface becomes dark (from graphite to coal). The permissible burning depth of wood is 20 mm.

- Surface. Most often used at home, implies a depth of burning material up to 5 mm. The method is easily feasible with a gas burner or conventional blowtorch.

Advantages and disadvantages of lumber firing

The main advantage of the technique is that it does not require impregnation, antiseptics, which are sometimes not environmentally friendly and may even contain toxic components. Other benefits of wood firing:

- the ability to do it yourself;

- lack of need for special skills, expensive tools;

- protection of the material from wind, moisture, mold, germs, insects, ultraviolet radiation;

- profitability;

- giving fire safety (re-ignition is almost impossible);

- reliable prevention of decay;

- ensuring wear resistance, increasing the service life.

The disadvantages include only the complexity of the process, which is performed without the availability of industrial equipment, because you have to manually burn each board, then clean and process it. Nevertheless, the unique texture, original appearance and unique technical characteristics of the burnt wood level all possible flaws and increase the popularity of the technology.

to contents ↑Firing at home - is it possible?

To burn the wood yourself, you must strictly adhere to the advice of specialists and the algorithm of the work. Since there are no vacuum ovens at home, more affordable appliances must be prepared in advance. As a source of flame for firing, you can use:

- gas burner;

- blowtorch;

- construction hairdryer;

- gas bottle with nozzle.

Wood cleaning tools will also be required. If you plan to work with small bars, planks, you can take a metal brush. For large lumber, it is better to prepare a grinding machine, grinder, drill with the appropriate nozzle. To conveniently overcast the remains of burning, you need to buy a fleitz (a brush with a soft pile).

Firing is carried out outdoors away from objects that may catch fire, especially from paper, rags, textiles, cardboard, plywood. Be sure to take away any solutions, compositions and other chemicals.

to contents ↑In order to comply with safety regulations, they work with gloves, goggles, and a fire extinguisher is kept nearby.It is advisable to work on a metal or stone surface, which is not afraid of heating.

Choice of wood species for firing and material requirements

Hardwood should not be fired (cherries, alders, etc.). In some cases, beech and hornbeam are fired, since they have sufficient density and are able to withstand heat. Work is more often carried out with conifers. Cedar is best suited for this purpose, you can also use spruce, pine, larch.

Conifers are distinguished by a variety of patterns, and after burning they acquire a unique structure. The more knots, complex bends were on the wood, the more decorative the result will be. It is important that the tree is moist, but contain no more than 15% moisture. You can also burn ready-made wooden products, coniferous veneers.

to contents ↑Preparation of material for firing

Fresh wood does not need to be carefully prepared for processing, because the flame will remove all the bumps, acting on the principle of grinding. It is only necessary to cut off large protrusions, knots, and also remove the resin - if its streaks light up during operation, the whole effect will be ruined. Too wet wood will have to be dried, otherwise moisture will deform it during evaporation, chips and cracks will appear.

Old wood is prepared more carefully. From it it is necessary to remove the remnants of paint, varnish, skinning, so that during firing there are no stains and there is no fire. If the tree was previously saturated with stain, it can be burned according to general rules. Sawn timber coated with drying oil is not subject to firing.

to contents ↑Woodwork blowtorch

For this option, you will need a blowtorch that has previously been heated as much as possible. If the heating is insufficient, a thick layer of soot will appear on the surface. The fire is directed strictly perpendicular to the position of the boards, moving the lamp slowly, evenly, paying attention to the change in color and structure of the material. The exposure time is chosen independently: it depends on the desired effect and the thickness of the workpiece.

After the firing is completed, primary grinding of the product is carried out. To do this, the boards are placed in turn on a stool or other convenient stand, carefully treated with a grinder, then brush off the dirt with a brush. At the end of the work, they are soaked with varnish, drying oil.

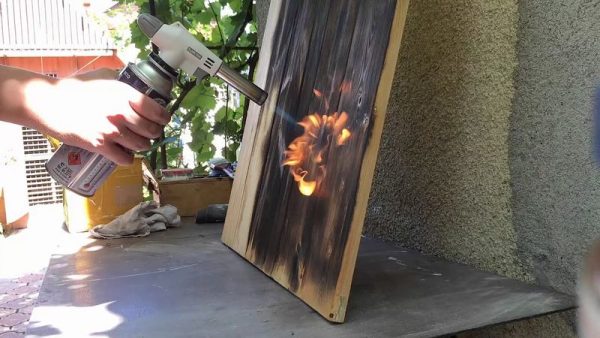

to contents ↑Burning wood with a gas burner

For a master, working with a torch is considered more convenient and easier than with a blowtorch. The effect will be more attractive, as the flame of the burner penetrates deeper into the structure of the tree. But in the process of firing, it is important to ensure that the fire is not too close to the lumber, otherwise they will burn out spots. Strong yellow firing flames are not permitted. It should be calm, oblong and bluish.

Start work from the top of the board. Spend a burner over the product like a stain with a brush: smoothly, evenly. Repeat the procedure 2-3 times, after spraying the material with water from a spray bottle. As it cools, the wood is treated by removing the loose burnt layer. Spend a grinder only along the fibers so as not to damage them. At the same time, they use the flute for sweeping soot, especially carefully removing deep-seated particles.

The quality of work is checked by wiping the wood with a napkin. If you want to give the material an antique look, then carry out brushing with a brush. Also, for the artificial aging of wood, it is possible to apply special pigments or special topcoats.

to contents ↑Does the burnt tree need extra protection?

The burnt wood has many advantages, and one of them is increased strength.Therefore, the material can be left in its original form after removal of carbon deposits. Nevertheless, experienced craftsmen always carry out additional processing of the tree, because after it the level of security will be even higher.

After firing, the product or lumber is usually treated with oil, which helps to improve the decorative and performance properties of wood. After that, transparent nitrocellulose varnish with protective properties or a mixture of varnish with artificial wax is most often applied. For the processing of facade wood using a solution of synthetic wax in turpentine.

to contents ↑The choice of oil for wood

Flax, hemp or tung oil is the ideal coating option for burnt lining or other wood for interior decoration. The liquid is applied with a brush or spray gun (depending on the scale of work). You can use tinted synthetic oils that give the tree a more noble look, mimicking valuable breeds. A mixture of colorless wax with oil gives an excellent result, which helps to emphasize the structure of the tree and protect it from external damage.

to contents ↑The use of fired lumber

Finished calcined lumber and products from it are highly appreciated by builders and designers. Doors, windows, gazebos and terraces, benches and tables, garden furniture and technical buildings are made of such wood. After firing, the tree is perfect for building fences, other fences, decorating floors and balconies, and decorating houses.

to contents ↑The use of burnt wood in interiors

Flamed wood is perfect for many interior styles, especially for country. After special varnishing or staining, it can be applied in retro, vintage, provence and other styles, which involve the use of artificially aged furniture and decor items. Most often in the interiors of apartments and houses you can see such products from burnt wood:

- caskets;

- panel;

- baguettes;

- chairs and tables;

- dressers;

- lockers.

In addition, the full decoration of the walls with burnt wood or the design of beams, ceilings looks beautiful in the design of the premises. The unique look of the material will provide a luxurious look to the whole house.

to contents ↑Creating facades from a burnt board

When creating facades of brick or wooden houses, such wood is used very often. After firing, the material becomes more durable and durable, therefore, with additional varnishing or oil soaking, it will serve without complaints for many years. Aesthetics, originality and environmental friendliness are the main qualities of burnt wood, making it one of the most popular materials in construction.