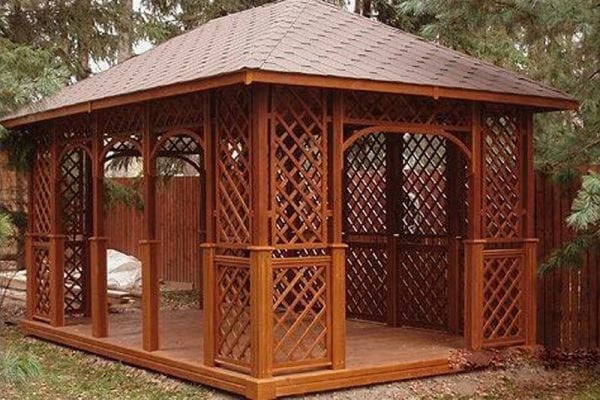

A wooden gazebo on the plot or near the cottage allows you to comfortably spend time in warm weather and acts as a successful addition to the surrounding landscape. The tree gives comfort, coziness, it is durable, but defenseless against rot and insects, loses its appearance under the influence of weather conditions and is afraid of fire. It is possible to protect the structure from external damage with the help of impregnation for the gazebo.

- How to choose impregnating compounds

- Varieties of protective equipment

- Proper processing for long-term protection

- Useful advice

Impregnation of the wooden base of the gazebo is able to protect the structure from:

- rot or mold appearing during rains;

- various insects;

- fire, for example, in case of accidental contact with a spark during a barbecue;

- darkening, when an unprocessed tree eventually acquires an unattractive gray appearance.

How to choose impregnating compounds

In order for the wooden building to be reliably protected from the weather, it is better to purchase autoclaved wood for the construction of the gazebo. Such boards do not rot over the course of many years, but if an ordinary tree was bought, then its life can be prolonged if it is treated with a special protective preparation.

When choosing an impregnation, you need to take into account:

- Climatic conditions of the area (large temperature fluctuations, whether there are frequent rains and other factors affecting the wood).

- The load on the board. Sex, in addition to weathering, is subject to abrasion. Impregnating compositions for the floor must be purchased taking into account the load on it. Floor impregnation should include components that increase the strength of the board.

- Proximity to the fire. If you plan to cook dishes on an open fire in the gazebo, then the floor and walls must be covered with flame retardant mixtures.

- Compatibility with varnish or paint, which will be painted construction. The product should not come into chemical conflict with subsequent decorative finishes and, if it is planned to be coated with colorless varnish, do not change the color of the wood.

- Toxicity. For outdoor gazebo the level of toxicity does not play a role, but when working with highly toxic solutions should use protective equipment.

- Convenience of application. The drug should be easily, without stains, distributed on the treated surface.

- Profitability (expense).

Varieties of protective equipment

In the construction market, many impregnations are provided for external works that can protect wooden buildings from adverse external influences. According to the composition of the base, they can be:

- Oil. Reliably protect from the effects of natural phenomena, prevent floor abrasion, but are easily combustible and change the color of wood. If barbecue is planned in the arbor, then you can not use such mixtures.

- Organically soluble, based on refined products, provide reliable protection for wood, increase its strength, but change color.With such a solution, it is good to process the floor of the building, and then paint it with a suitable dye in composition.

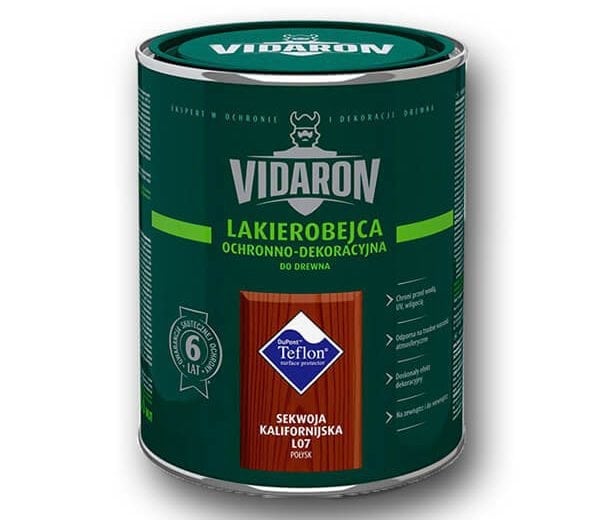

- Water soluble. Most popular among the population. They are durable, non-toxic, used for outdoor or indoor use, actively penetrate the structure of wood, non-combustible.

The chemical composition of the impregnation can be as follows:

- Bituminous. They are distinguished by low cost and good penetration (up to 7 mm) into the structure of wood. Available in a paste-like mass, they provide high-quality protection against moisture, reliably protect the floor from abrasion, repel insects, but change the color of the tree. The structure can be treated with this mixture if color decorative painting is planned.

- Alkyd. Use only on unpainted or well-cleaned wood surfaces. Often wax, various oils and antiseptic additives are added to alkyd resins. Reliably protect from moisture, ultraviolet, but combustible.

- Acrylic Some of the most popular for processing boards can be used on old or new surfaces. Acrylic after application forms a film that prevents the formation of fungi and mold, non-combustible. Often acrylic impregnations are produced combined: with protective additives from fire, from insects.

Intended use, impregnating mixtures can protect the wood base from such problems:

- Darkening: it is recommended to process the arbor immediately after construction. If this is not done, then the tree will get an unpleasant gray color. This treatment is especially relevant if you plan not to hide a beautiful wood structure, but to coat the structure with colorless varnish. The chemical formula of such compounds lasts a long time, helping the tree maintain its natural color.

- Rotting, drying out or cracking resulting from uneven evaporation of moisture from joints, floors or walls. The use of these solutions will prevent decay or cracking, normalize the air exchange of the wood structure, and reduce the risk of deformation of the boards.

- Fire: impregnations reduce the flammability of the boards, but give the woody base a pinkish tint. They preferably cover the floor and walls before applying tinting compositions.

There are also decorative mixtures that can give the material the necessary color. Often produced on a water basis, non-toxic, but may not contain protective additives.

to contents ↑Proper processing for long-term protection

In order for the gazebo to please its fresh look for a long time, it must be properly treated with protective equipment. After the necessary solution is purchased, you need to prepare the tools:

- "Skins" of different grain sizes, you can use a grinding machine;

- brushes or roller (sprayer is not recommended - this tool will reduce the quality of impregnation);

- protective equipment (if the mixture is toxic).

Before proceeding with the impregnation, it is necessary to prepare the area for work. The preparation process is the same as before staining or priming:

- The wood base is sanded with an emery cloth or grinder.

- Dust, chips, and dirt are removed from the surface. It is convenient to carry out cleaning using a vacuum cleaner.

- After completing the preparatory work, you can begin to process the boards. It occurs as follows:

- After opening the can, its contents are thoroughly mixed.

- Apply impregnating solutions quickly, evenly distributing them over the entire area. If you paint over the surface in separate sections, then the mixture is absorbed unevenly.

- After applying the first coat, wait until it dries completely (about two hours). If "villi" have risen at the boards (this happens when using water-soluble preparations), then they must be cleaned again.

- The second and third layers are applied similarly to the first.After the last layer has dried, the structure can be painted.

Useful advice

Cracks on a wooden beam are almost impossible to prevent. Moisture begins to accumulate in them, which will lead to the destruction of the material. To avoid this, you need to:

- Re-treat small cracks with protective mixtures, prime and then paint over.

- Large cracks are first smeared with impregnating solutions, after which they are filled with putty or plastoelastic non-curing sealant, the leveled base is painted.

About, how to paint the gazebo, we will talk in the next article.

If you take care of the gazebo in a timely manner, then it will delight you with its appearance for a long time, allowing you to relax comfortably on summer days.