Plywood is widely used not only in furniture manufacturing, but also in construction. An unprocessed plywood surface does not look aesthetically pleasing, therefore it is customary to refine it by wallpapering or painting. Coating with paints and varnishes, in addition to the aesthetic appearance, additionally gives such qualities as resistance to moisture.

- Why is it necessary to prime?

- How to choose a primer

- Classification and soil features

- Acrylic

- Alkyd

- Polyurethane and Epoxy

- Shellac

- Phenolic

- Drying oil

- Styrene

- Nitrocellulose varnish

In order for the paint applied to the wooden base to fulfill its functions as long as possible and maintain an attractive appearance, it is necessary to treat the surface with a primer before painting with paints and varnishes.

to contents ↑Why is it necessary to prime?

Several reasons for which a primer coating of a plywood base is necessary:

- Primer plywood increases the resistance of wood to the damaging effects of moisture, reduces the absorption of water by the wood and prevents swelling and deformation. Subsequent coating with water-repellent paints and varnishes increases the wood's resistance to water.

- The soil and paint applied on a wooden base, which have bactericidal properties, prevent decay.

- The primer prevents cracking of wood.

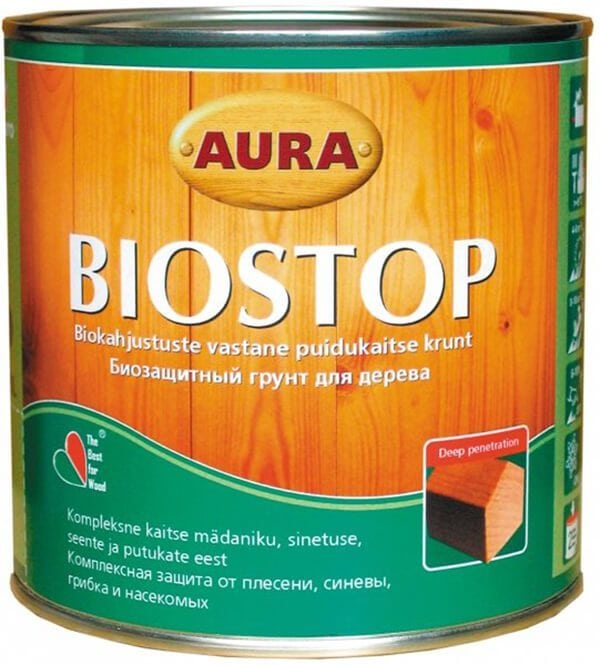

- Using a primer for painting, you can protect plywood from the formation of mold and fungal infections. This effect is achieved due to the availability of primers with specific additives on sale.

How to choose a primer

Before buying a primer suitable for processing plywood surfaces, you must pay attention to the following properties of the primer:

- It is necessary that the selected primer was designed specifically for the impregnation of plywood and wood.

- The primer must be compatible with the paint.

- It is better if it is soil with special antibacterial additives, then it can protect the surface of the tree from decay, mold and fungal formations.

- If the surface to be treated is in the open air and will subsequently be exposed to direct sunlight and precipitation, then pay attention to primers having water-repellent properties.

- Soil with water-repellent properties will have to be used in any case, if all other building materials used during construction have such qualities.

- To treat the surface of plywood, the same composition as for chipboard is suitable - the material will increase adhesion to the base and paints.

- When choosing a primer, it is necessary to take into account the degree of humidity in the room.

- It is better to use alkyd compounds or water-acrylic for priming plywood.

- Nitrocellulose paints NTs-1227 or NTs-48 can be used as soil.

Classification and soil features

As a rule, all priming materials incorporate film-forming substances (polymers, adhesives, oils, special additives). Each manufacturer creates its own soil formula:

- introduces fillers into it, providing quick drying, viscosity and other special properties;

- Adds coloring pigments;

- fills with bactericidal additives.

Depending on the base, the composition may be oil, alkyd, acrylic, mineral.

to contents ↑During operation, surfaces treated with different soils demonstrate different characteristics and qualities. Therefore, it is important before buying a primer to determine what properties the surface should have in the future:

Acrylic

This primer is made on the basis of acrylic, in connection with which it demonstrates the best qualities inherent in acrylic paint and impregnation. It dries quickly, has no toxic smell. Acrylic primer forms a protective film and penetrates into the pores and cracks of wood, providing additional mechanical protection for the surface of the base. These properties can be enhanced by painting, for which paint and varnish materials compatible with the soil are used.

Alkyd

Perfectly applied to raw plywood. On wooden surfaces forms an ideal coating. The resulting film not only strengthens and protects the base, but also allows you to subsequently seamlessly apply paints and varnishes. Alkyd materials are an excellent impregnation. They can be applied at will in one or several layers. Alkyd primers dry much longer than acrylic and have sharp toxic odors.

to contents ↑Polyurethane and Epoxy

Made on the basis of epoxy resin and polyurethane. Before using them, you should carefully study the instructions for use.

Shellac

This is the best primer for coating wooden surfaces. Can be used as an impregnation before applying varnish. For the manufacture of milk is used insect juice.

Phenolic

Most often used for primers plywood and other wooden surfaces in the furniture industry. They are characterized by high impregnating ability and low price. On average, it takes 10 hours to fully dry. The disadvantage is that the phenol contained in the primer is not safe for human health.

Drying oil

Due to its high ability to protect the surface from liquids and give the base water-repellent properties, it is used for exterior and interior decoration.

Styrene

Promote the formation of plywood films on the surface. Perfectly protect materials from decay and mold. Compatible with alkyd and phthalic enamels.

Nitrocellulose varnish

This varnish is used as a primer designed specifically for woodwork.

It is not difficult to choose a primer for a plywood base. The main thing is to take into account the features of the room and the acquired building material.