Metal pipes are needed everywhere - for the installation of gutters, the laying of all types of communications, for the installation of load-bearing structures and much more. Metal is strong, durable and, when used correctly, can last for decades. It has only one drawback: defenseless against corrosion.

- Priming goals

- The Basics of Choosing the Right Primer

- Product purpose

- Quality and type of steel

- Content Temperature

- Subtleties of the processing process

Many people try to protect the pipes by simply painting them with oil paint, but this is not enough, the coating soon begins to peel off, fall off, and the metal surface is again defenseless against environmental aggression. For the long service life of the pipes, it is necessary not only to paint them, but to carry out a complete treatment with the obligatory application of a primer.

to contents ↑Priming goals

The use of a primer before staining has several advantages:

- For the treatment of iron products, as a rule, compositions with an anti-corrosion effect are used, capable of not only smoothing the surface of the pipes as much as possible, ensuring uniform application of paint, but also protecting them from rust.

- A significant increase in the adhesion strength of the paintwork to the base.

- Reducing construction costs, because when painting steel surfaces after applying a primer, enamel or varnish is much less required.

- Able to compensate for the difference in thermal coefficients inside the pipe and the surrounding atmosphere, giving additional strength to the coating.

The Basics of Choosing the Right Primer

When going to paint and acquiring a primer for metal, you need to consider several important factors.

Product purpose

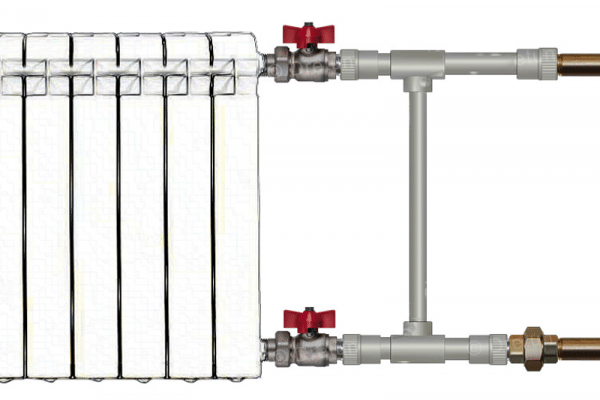

- for central heating radiators - pipes are subject to temperature differences;

- for supplying cold water - the surface of the pipes will always be cold and wet;

- for hot water: constantly exposed to high temperatures, dry surfaces;

- gas;

- on the street (weather conditions, atmospheric effects should be taken into account);

- in room.

Quality and type of steel

To ensure the necessary protection and extend the life of the product, depending on its purpose, mixtures are used:

- Primers-insulators. They are made on the basis of typical paint compositions (white, red lead) with the addition of special additives, for example, an epoxy mixture. When applied, a strong thin film is created on the surface that prevents the product from contacting with the atmosphere. Good for outdoor pipes.

- Phosphating type, two-component primers. They are a mixture of active components that enhance the passivation of metal and phosphoric acid, are suitable for processing all types of steel pipes, and have high adhesion. Often used before applying any coatings, enhancing their protective properties and reducing paint consumption.

- Passivating coatings alter electrochemical properties, slowing down the formation of corrosion and rust. The chemical properties of the composition protect, even if water has penetrated under the applied layer. Good to use for wet pipes.

- Soil protector is a metal suspension dissolved in a paint and varnish base. Drying, forms a thin metal film, has high protective functions.

- Inhibitors are a new generation of protective water-based and oil-based enamels that reliably and effectively protect against corrosion. Suitable for pipes in humid or outdoor conditions.

- Primer-transformer (for rust) based on phosphoric acid. The mixture converts iron oxide (rust) to iron phosphate. The result of this chemical reaction is a protective insoluble film that is able to partially restore the coating corroded by corrosion.

Content Temperature

An important role is played by the temperature of the pipes. It also needs to be taken into account when choosing the heat resistance of the primer mixture and the subsequent finishing layer:

- Up to 60 ° C. Usually this temperature mode is quite sufficient for central heating radiators and hot water. Subject to all stages of processing, you can use any primer on a general-purpose paint base. The paint lays on them evenly, reducing the consumption of material, does not fade, does not exfoliate.

- Up to 100 ° C. These compounds are best used in private homes where the owners themselves regulate the heating temperature, and the heating of radiators can exceed 60 ° C. Soil is suitable for this ordinary, only a decorative coating must be taken with pigments resistant to fading.

- Soil mixtures are also available that can withstand temperatures above 300 ° C. Used only in industrial enterprises.

to contents ↑When purchasing the necessary solution in the store, it is very important to find out the primer consumption for metal. Usually it is about 100 g per 1 m2.

Subtleties of the processing process

The application of soil to metal pipes and radiators is similar to that on other surfaces, but has some features:

- The surface is thoroughly cleaned from a layer of old paint and rust to shine. For this purpose, it is better to use metal brushes. When cleaning hard-to-reach spots of heating radiators, you can take brushes made of metal.

- If the layer of old paint does not leave well, then you need to use a special softening solution, which is applied to the pipes and radiators and covered with a film. After waiting a little time, the extra layers can be easily removed with a spatula.

- After this, the area of work must be well cleaned with a “skin”, gradually changing its grain size to finer, and cleaning the metal to shine and smoothness.

- Rinse and allow to dry.

- Treat dried products with White Spirit or any other suitable degreaser and dry.

The next step is to start applying the primer. Depending on the size of the surface and the composition of the primer mixture, it is applied:

- With a brush. The brush provides a more thorough treatment of uneven surfaces, but on large, even areas (for example, long thin pipes), it will work for a long time and the material consumption will be large.

- Rollers of different sizes. The use of small rollers in small areas significantly reduces the consumption of protective composition.

- Airbrush.

Priming occurs in several layers. The first is applied very thinly, filling small bumps and cracks.

After drying, 1-3 more layers are added as needed. The primer consumption will decrease with each new coat.

The processing process is preferably carried out on products at room temperature. Heating radiators should be disconnected for a while. This will ensure uniform drying, increase the quality of work and reduce the consumption of primer.

Painted decorative coatings will fall on the surface thus treated perfectly evenly, without sagging and streaks, providing the pipe with additional protection against moisture and temperature extremes and significantly extending its service life. If you take the time and correctly carry out all the stages of processing before painting, then the water supply and heating systems will not require replacement for a long time.

Primer for pipes is an obligatory stage of processing, which allows to well fix the future coating, to provide protection against corrosion. The primer is chosen depending on the purpose of the pipe, whether it be a radiator or a gas pipeline.