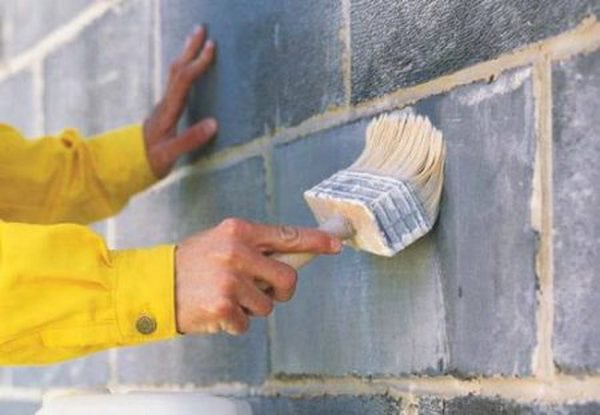

One of the most important qualities of the base surface is adhesion, that is, its ability to adhere to dissimilar solid or liquid bodies. The primer for internal work improves the adhesion properties of the treated surface, so that the base adheres well to paint, varnish, wood, aerated concrete or other decorative materials.

- Advantages of Acrylic Compounds

- Composition

- Varieties

- Universal primers

- Alkyd and alkyd-acrylic compounds

- Compositions for metal

- Mixes for concrete

- Material consumption

Primers are made on the basis of alkyd resins, minerals, acrylic and other elements. The most popular material for interior use are acrylic primers. Such compounds are basically composed of acrylic and latex.

to contents ↑Advantages of Acrylic Compounds

The main advantages of acrylic primers include the following:

- Effective in improving the properties of porous and loose substrates, as they compact and make their structural elements more uniform.

- Increase the adhesive properties of the surface, which facilitates its finish.

- Protect the surface from moisture. A special effect is provided by water-dispersed acrylic compositions during the processing of gas silicate coatings.

- Due to the increase in water-repellent properties, the treated surface reduces the absorption of liquid, which reduces the consumption of liquid materials in the future, while the colors will be more saturated.

- Acrylic makes glossy gloss more intense.

- Pre-treatment with a primer on a dark base, allows you to apply light paint on top, and the painted coating will not seem dull.

- Priming of metal prevents corrosion processes, as well as burnout of paint under sunlight.

Composition

The composition of the primer mixture may vary depending on the tasks. However, without fail the composition contains the following substances:

- water dispersion;

- film-forming elements (bitumen, adhesives, resins, oils);

- drying accelerator components,

- pigments

- auxiliary components (chalk, marble particles, mica);

- additives for acquiring special properties by the surface (foam suppressor, biocide, ethylene glycol and so on).

If it is necessary to set certain properties for the composition, the specific gravity of one or another substance may change.

to contents ↑For internal work, compounds based on water are used, and for the finishing of external surfaces - based on organic solvents.

Varieties

Primers are divided into two types:

- penetrating compounds that are deeply absorbed (up to 100 millimeters) into the structure of the material, providing adhesion at a greater depth;

- strengthening compounds that affect only the surface of the base.

Universal primers

Universal soils are characterized by opacity and are made on the basis of acrylic copolymers. Such primers have decent adhesive properties and interact well with paints and varnishes (for example, with acrylic, latex or alkyd paints).

Universal primers are also used to prepare concrete, aerated concrete, drywall, brick, plaster and wooden surfaces. Universal compounds are also suitable for applying to fiberglass wallpaper, plaster and past-painted walls.

Note! If there is a need to accentuate any property (for example, increased corrosion resistance, the ability to reflect, etc.), it is more correct to purchase a special composition intended for this.

to contents ↑Alkyd and alkyd-acrylic compounds

For the preparation of surfaces that have previously been painted, alkyd-based formulations are best suited. Alkyd primers are highly adhesion and adhere to such difficult surfaces as polyvinyl chloride, fiberglass, galvanized, tile, metals.

Mixtures including alkides and acrylics are the best option for wood preparation and are well suited for steel substrates. In the case of wood, alkyd-acrylic primer swells the structure of the material, which creates good conditions for finishing work.

When working with metal, an alkyd-acrylic mixture can even be used as a finish.

to contents ↑Note! Compounds with alkyds cannot be used to treat plaster and gypsum.

Compositions for metal

In this case, the choice of primer depends on the type of metal. For example, when it comes to aluminum, the ideal option is a mixture containing phosphates. To prevent corrosion processes, it is necessary to use compounds based on alkyds or alkyd-urethane primers.

Mixes for concrete

To prepare a concrete floor, an epoxy or polyurethane primer is best suited. Before processing concrete with enamel, acrylic mixtures are often used.

Material consumption

Factors affecting primer consumption:

- Type of surface. For example, if the base is friable and porous, the material consumption will be increased. In this case, you need the appropriate brand of primer - acrylic deep penetration.

- The number of layers applied. If we are talking about a universal composition, a liter of primer is enough to cover a couple of words of 10-12 square meters. m smooth surface. Rough or highly absorbent materials (such as drywall or concrete) will require a higher consumption of primer mix. The package indicates the required number of layers when processing this or that type of material.

- Used tools. For example, working with a brush requires a lot of labor, however, the primer consumption will be less than when using a roller. The fact is that the roller absorbs the mixture more strongly. The best option for the lowest flow rate is to use a spray gun.

Thus, the choice of primer for internal work is dictated by many factors, depending on the type of material being processed and the operating conditions of the surface. The correct choice of the primer mixture will make it possible to save money on the consumption of the primer, save time for finishing work and allow you to carry out repairs better.