Primers are used to create a solid foundation for finishing work. This type of material helps to prepare surfaces for painting, reduces the consumption of expensive paints and varnishes. A popular type of coating is GF-021 primer. It is intended for priming internal and external surfaces and seriously improves their operational properties.

- Material Description

- Properties of the soil and its purpose

- Pros and cons of funds

- Primer Characteristics

- GOST data

- Shades

- Storage

- Security

- Certification

- Proper surface preparation

- Priming work

- Soil dilution

- Material consumption

- Possible mistakes

Material Description

Primer GF-021 is a universal material, in form it is a suspension - a liquid in which solid particles are present. The composition of the mixture is regulated by GOST, the soil includes:

- alkyd varnish;

- desiccant;

- mineral substances;

- stabilizing additives;

- pigments

- corrosion inhibitors;

- other fillers.

The primer is a type of alkyd, or glyphthal, so when used it is not absorbed even in the most porous surfaces (including wood). After processing the base, a special layer (film) is created on the latter, which provides protection from external influences.

to contents ↑Properties of the soil and its purpose

The use of a primer is justified on different types of surfaces. It helps reduce consumption by 1 sq. Km. m of paint, enamel, varnish and other materials, can serve as an independent coating or prepare the base for subsequent work. It is acceptable to use GF-021 on such surfaces:

- wooden;

- metal;

- plastic ones.

It is possible to apply the product on concrete, plywood, MDF, chipboard, rust work is acceptable to stop its spread. The tool will protect metal structures, car frame, home and industrial products from moisture, the action of microbes and fungus. Thanks to "endurance" when the temperature fluctuates, you can use the soil outside the premises to protect the walls of houses, other buildings.

to contents ↑Pros and cons of funds

The quality of the material is very high, and this determines the properties and characteristics of the primer GF-021. Its advantages are as follows:

- powerful anti-corrosion effect;

- resistance to adverse weather conditions;

- quick drying;

- reliable protection against various chemicals - household chemicals, oils, greases, corrosive liquids;

- the ability to apply in high humidity conditions;

- a serious improvement in adhesion between the base and subsequent layers;

- reduction in consumption of the main material.

The material is compatible with all major types of paint - alkyd, oil-bitumen coatings, with other paint products. For example, it is often used for application under alkyd enamel PF-115.

There are few disadvantages of the tool. The primer is quick-drying, as indicated by the manufacturer, according to the standard, it completely dries out in a day.But in fact, this period can increase, and it is extremely undesirable to allow temperature fluctuations during drying. Another drawback is this: some paints curl when applied to the soil, if it has not completely dried out, so it is important to completely dry the coating.

to contents ↑Primer Characteristics

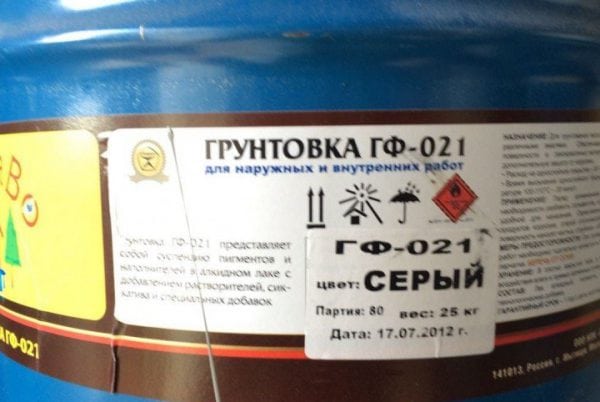

Technical characteristics of the product are recorded in GOST 25129-82. Only gray soil has a different passport; it is prepared not according to GOST, but according to TU. The following is a description of the main indicators and data decryption.

GOST data

After applying to the base, a high-density film is created, it looks even, uniform, without impurities, matte or slightly glossy. General characteristics are as follows:

- conditional viscosity on the device VZ-4 viscometer at a temperature of +20 degrees - 45 s;

- the need to dilute the primer - not more than 20-25%;

- the content of non-volatiles - 54-60%;

- milling degree - up to 40 microns;

- drying time to the third degree at a temperature of up to +105 degrees - 35 minutes, at a temperature of +20 degrees - 24 hours;

- the hardness of the film on the M-3 device is 0.35 units;

- bending elasticity - 1 mm;

- impact strength on the U-1 device - 50 cm;

- coating adhesion - 1 point;

- resistance to the action of sodium chloride 3% - 24 hours, to the action of mineral oil - 48 hours.

The thickness (μm) of the soil layer is 15-20, usually it is applied in 2 layers, while the second may have a slightly smaller thickness.

to contents ↑Shades

Primer colors GF-021 - red-brown, light gray. On request, it is possible to manufacture a black product. The depth of shade depends on the characteristics of the production of a particular party.

to contents ↑Storage

The shelf life of the soil is 2 years. At the same time, it is important to observe storage conditions - in factory banks, without access to sunlight, at a humidity level of up to 80%. You can freeze the material (up to -20 degrees), this will not damage its properties.

Security

According to the manufacturer’s instructions, the primer is a highly flammable material, toxic due to the presence of diluents. Vapors of these substances pose a direct danger to humans, so the primer is not intended for use without personal protective equipment (gloves, respirator, thick clothing). It is important to protect against ingress of soil and its vapors:

- skin

- Airways;

- mucous membranes.

to contents ↑Fire regulations should also be strictly observed. The workshops should have fire protection equipment; when priming and painting surfaces, you must not smoke, use fire. If material comes into contact with the skin, immediately rinse it with water. The dried coating is completely safe for humans.

Certification

By law, each batch of material must undergo mandatory certification. In this regard, a certificate of conformity, a quality certificate, a safety certificate (hygienic certificate) are attached to any bank of funds. Soil is packed up in containers of 900 g, 2.8 kg, as well as in cans of industrial volume - 25-250 kg.

Proper surface preparation

When processing metal structures, the tool can replace staining, as it has an even, pleasant shade. The resulting film will be smooth, easy to grind. All these conditions are met if the surface is properly prepared. To do this, do the following:

- clean from rust, dirt, old paint by mechanical means;

- remove stains of grease, dust;

- exclude the presence of burrs, seams, cracks, craters;

- to cover window and doorways with construction tape if work is carried out indoors.

Priming work

Primed prepared base can be in many ways. It is permissible to use a roller or brush, spraying with special devices, rolling, spraying in an electrostatic field.

The last option for applying the soil is carried out using the pump and the construction gun included in the network. After giving the material an electric charge, it will be sprayed. This method is the most economical, it is recommended where it is necessary to process large areas, where there are hard-to-reach spots.

When pneumatic spraying uses compressed air, which pushes the soil in the form of a fine dispersed mass. This method allows you to get a thicker layer of soil, so as not to re-primer. When dousing (rolling), small surfaces are usually primed, from which the material can easily drain.

to contents ↑Soil dilution

How to dilute the material is indicated in the instructions for use. It is necessary to dilute if viscosity exceeds the established norm. The primer solvent GF-021 is:

- RE-3V, 4V (for use in an electric field);

- turpentine;

- White Spirit;

- solvent;

- xylene.

to contents ↑The mass of the solvent should not exceed 25% by weight of the soil itself. After the introduction of the solvent, the agent must be thoroughly mixed.

Material consumption

Usually consumption per 1 square. m of metal and other surfaces is 60-100 g, depending on the application method. Such costs are obtained for one primer layer with an average thickness of up to 20 microns.

Possible mistakes

If you do not clean the base of grease, oil stains, subsequently they appear on the surface. Before the subsequent painting, it is necessary to allow the soil to completely dry, checking this with a film, otherwise the quality of the coating will be reduced. The material contains adhesives, and surfaces not subject to priming must be protected. It is also not recommended to change the primer to PVA glue, water emulsion, as they do not have the necessary properties in terms of adhesion and strength of the created film.