Before painting the walls or covering them with wallpaper, experts recommend priming the wall surface. A person without a building education will not immediately understand how important this process is. But professionals will always note that it is impossible to neglect the primer in any case. Therefore, let's talk later in this article about what an oil primer is, what it is made of and what it is used for.

- The main purpose of the primer

- What is an oil based primer?

- Brief description of oil soil

- Advantages of oil based primers

- Types of oil soil

- Features of the use of oil soil

- Oil primer

The main purpose of the primer

For an ideal end result of repair work inside the premises for various purposes, whether it is painting or using roll wallpaper, the wall surface is covered with a primer. This is necessary so that the plaster does not fall off and crack over time, and the wallpaper does not go in whole stripes.

The primer, thanks to its good technical characteristics, contributes to better adhesion of the putty and the finishing material, helping the wall to maintain the original beauty acquired after repair.

For the result of your work to be magnificent, never forget about such an important moment as priming. But what tool to choose for this? Shops of building and decoration materials offer so many options that it is not a sin to be confused by an ordinary person. Let's look into this further.

to contents ↑What is an oil based primer?

An oil alkyd compound is called an oil based primer, which contains synthetic synthetic oil resins. In addition, it contains drying oil and grated paint. These components determine the future color tone of the product.

An important component of the oil primer is the solvent, but it is present only in the spray. If the product is sold in cans and should be applied to the surface with a brush or roller, then there will be no solvent in it.

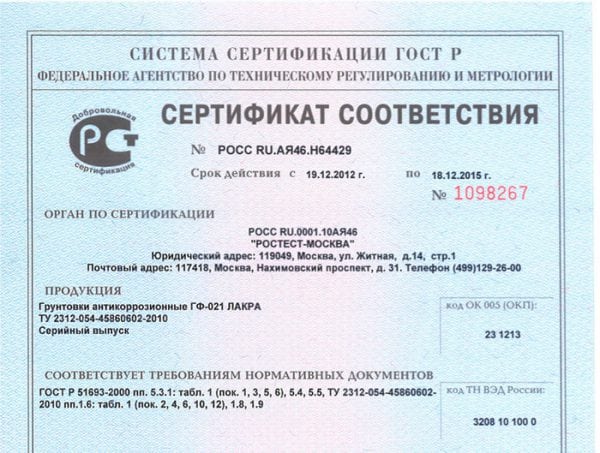

Note that it is worth buying only products with a quality certificate. So you can protect yourself from the risk of buying a fake or low-quality product.

Brief description of oil soil

An oil based primer often has a matte finish. From a design point of view, it is a universal product, since it can be tinted.

The average material consumption is 50 - 100 g. per 1 sq.m., however, this parameter is determined by the scope and absorbent properties of the surface to be coated.

The oil primer layer has a coating thickness of up to 1 mm. It is possible to achieve complete drying of the first layer of the agent only after one day. Only after this time can we proceed to the application of the second layer.Before using it, manufacturers recommend carefully placing the composition.

to contents ↑Advantages of oil based primers

These funds have a number of positive qualities:

- great for preparing the surface for painting with oil paint;

- provide wood with high resistance to moisture;

- perform the function of a natural surface antiseptic;

- it is easy to decorate primed surfaces, since an oil-based product can be tinted and its texture or color practically does not appear through the top coat of paint.

Types of oil soil

Today you can buy two types of acrylic oil-based primers. What type of primer is it intended for? We will answer this question further:

- Universal, due to its excellent technical characteristics, it is perfect for covering surfaces made of brick or concrete, but it is completely unsuitable for wood and metal. It is these materials that are ideal for self-processing of walls before they are painted or glued with wallpaper;

- Primer paint is intended for the treatment of metal or wooden surfaces. It has a standard set of characteristics for soil, but in addition it is also characterized by antifungal properties. Often it is white, therefore, after priming with such a tool, the surface appears painted.

Features of the use of oil soil

When performing priming work, it is important to remember the following rule: the product must match the composition of the paint used. In other words, alkyd enamel will lie perfectly on alkyd soil, and oil enamel on oil. Otherwise, there will be problems with the wall coating in the form of cracks and partial chips.

Oil primer

To do the work yourself, you will need to buy a universal type oil primer with a quality certificate and a special tool:

- a cuvette with a ribbed squeezing place into which soil is poured;

- roller and brush, which process hard-to-reach corners;

- telescopic handle if you do not have a stepladder.

Phased work involves the following operations:

- pour the finished soil into the cuvette;

- put the roller on the telescopic tube and soak it in the tool. Then, with a few movements along the ribbed surface, remove the excess primer from the roller;

- apply the product on the wall.

Note that it is allowed to apply several layers of primer. It is important to observe the current time for drying. So the second layer of the agent should be applied only when you are convinced of the complete drying of the first layer. According to manufacturers instructions, this may take about 5-6 hours. But depending on external factors, this indicator may vary. That's all. In fact, nothing complicated.