The use of a primer is necessary to increase the adhesion of the base with the finishing or building material. Soil is also used to strengthen the surface of walls, ceilings, floors, stoves and other surfaces. After its application, paint (enamel), decorative plaster, wallpaper can be used. But what if you have to work with an object whose temperature is elevated? For example, it can be stoves, fireplaces, places close to the heating system or heat sources. For such purposes, a special heat-resistant primer is used, which guarantees the quality of finish and is resistant to fire.

- Features of the composition

- The use of heat-resistant primers for metal

- The principle of the soil

- Temperature ranges

Features of the composition

The primer is used in order to penetrate the base to strengthen it, remove dust, prepare it for applying compositions with different densities and viscosities. Heat-resistant primer should be applied to the work surface in the same way as usual for many painters and plasterers. However, instead of ordinary oils, resins, and adhesives, heat-resistant primers include acrylic and polymers that are resistant to elevated temperatures. This allows you to prepare stoves, fireplaces, barbecues for decoration, moreover, applying high-temperature enamel will create an even coating, without cracks and chips.

The application of soil saves building material, and in cases of work with stoves and fireplaces provides the proper level of adhesion for plaster or other compounds. Without a bonding element in the form of soil, due to different heat capacity, over time, cracks would appear on the surface of enamel, plaster or brick, which would only increase.

to contents ↑The use of heat-resistant primers for metal

Heating radiators, steel pipes, heating boilers and heat shields are made of metal. Its high temperature during operation should not affect the surface quality. For this, heat-resistant enamels, paints and, of course, primers are used. Without applying heat-resistant soil, the use of enamel will be inappropriate:

- A rusty, untreated surface with a large holding of small debris will spoil the appearance of the product. Application of the soil will bind the smallest particles of dust, rust, which will improve the smoothness and evenness of the surface.

- The amount of enamel spent on metal processing without the use of soil will be significantly higher. Given its cost, it is advisable to always prime the metal.

- Enamel will increase adhesion to the metal after applying the primer, which will extend the period of operation of the surface, improve the appearance.

If you carefully treat the surface of the metal, the risk of stains from oxides, corrosion damage to the metal is reduced.

to contents ↑The principle of the soil

Heat-resistant high-quality primer converts rust, oxide film on metal into a stable, neutral coating that can withstand high temperatures without changing its properties. It is on this film that enamels are applied that only enhance it.

Even treating stoves and fireplaces from metal only with soil, you can get a beautiful, pleasant to the touch and resistant surface, which will simplify the care of the device.

In addition, an intermediate layer in the form of soil compensates for thermal expansion in various types of coatings and substrates. The absorption of liquids is reduced, which in turn extends the period of use of enamels or other coatings. This is also true for brick fireplaces and stoves that can absorb condensation or moisture from the environment.

Due to all these advantages, the application of a heat-resistant primer is considered advisable, given the lower cost of the soil, in contrast to expensive heat-resistant enamels.

to contents ↑

Temperature ranges

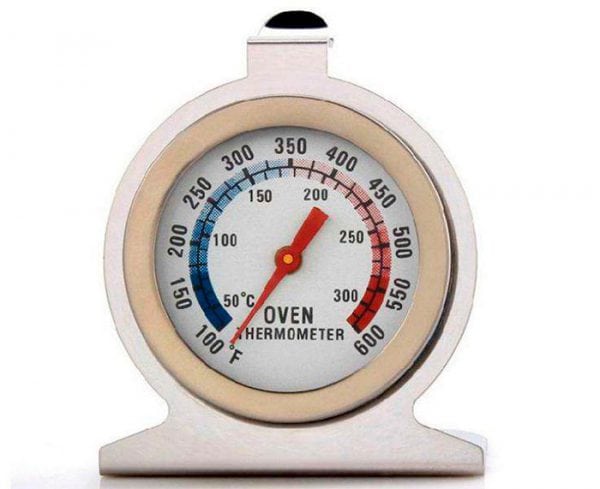

Manufacturers distinguish compositions according to temperature indicators at which there is no change in the quality and properties of the soil. Most often, the gradient is as follows:

- Up to 60 degrees Celsius - are demanded for metal processing in heating systems, in private houses and apartments. Even a slight increase in the temperature of water heating does not lead to visible damage to the protective film. They are ideal as a preparation before painting with conventional enamels of wide application.

- Up to 100 degrees Celsius - used for processing steam heating systems, fireplaces and stoves on the outside. It is better to use enamels with saturated pigment, soil treatment should be thorough, without gaps and untreated areas. Be sure to check with the seller if the primer and enamel are compatible for a better decorative effect. A primer of this type does not have a high cost and can be effectively used on any household objects (baths, boiler rooms, heating appliances).

- Up to 300 degrees Celsius - buy primers with mandatory fixation of the maximum operating temperature by the manufacturer. 300 degrees is already a temperature close to burning fuel, the primer should not emit toxic substances, exclude the risk of smoldering or burning.

- Over 300 degrees Celsius - professional surface treatment with such a level of thermal radiation excludes the application of primers, since high-temperature ceramic or any other enamels will be applied immediately. This is due to the fact that primers with any composition can not prevent the separation of paint and base material.

Before buying a primer, consult the seller, carefully study the manufacturer's recommendations. With proper surface treatment, the primer can significantly extend the life of the product, as well as significantly reduce enamel consumptionpaint or other coatings.