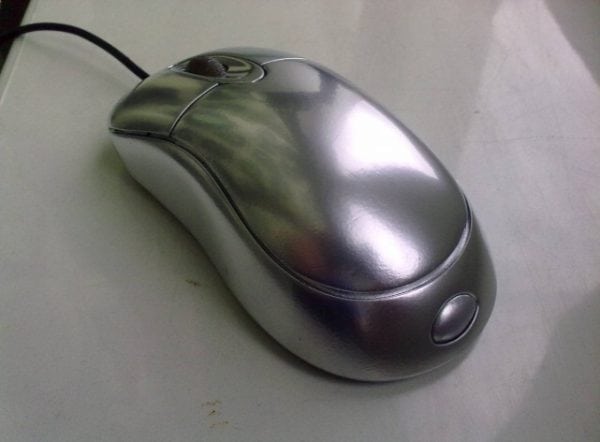

The application of chromium to plastic is often practiced by car owners when they want to give them a more aesthetic appearance. Chrome plating parts can be done at home. This will save a significant amount on the services of a car service workshop.

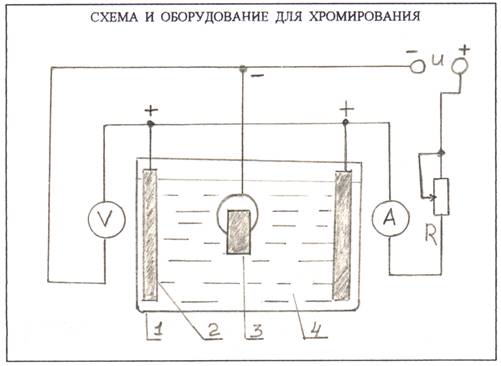

In the figure above are located:

- glass container;

- anode;

- a part that undergoes chrome plating;

- electrolyte solution.

Process features

Both plastic parts and metal surfaces can be chrome plated. Work at home should be carried out in a well-ventilated area, since during the process chemical reagents will inevitably fall into the air, which can adversely affect health. If the reagent gets on the skin, dangerous burns are likely. In addition, chemical poisoning of the body is not uncommon.

The best place to do it yourself is a garage or other technical premises. As a precaution, use a respirator, safety glasses, rubber gloves and an apron.

For the work you will need the following devices:

- a container, in which quality an ordinary 3-liter glass jar or a plastic bucket will fit (the choice of a specific container depends on the configuration of the part to be chrome plated);

- wooden box (it must be insulated with fiberglass, and then insulated with sand);

- a heating element, since chromium plating is carried out at a high temperature (an ordinary heater is suitable);

- thermometer (the scale should reach 100 degrees Celsius);

- plywood sheet;

- clamp;

- bracket for fixing the workpieces;

Preparatory work

To carry out chrome plating, you will need galvanic equipment that you can assemble yourself. First of all, we select a brush with thick bristles. Next, remove the bristles, and wrap the brush with a lead wire. Then we make a special brush with a hollow plexiglass body, which we will continue to fill with electrolyte.

The current source will be a powerful transformer, to which we will attach the anode and cathode. Also, a car battery can be used as a source of electricity at home. However, the operation scheme in this case will be different.

We attach a diode to the brush prepared in advance, and connect the anode to the cable directed to the step-down transformer winding. The cathode itself will be fixed on the chrome-plated part. If the power source is the car’s battery, there is no diode in the circuit - this is the difference mentioned above.

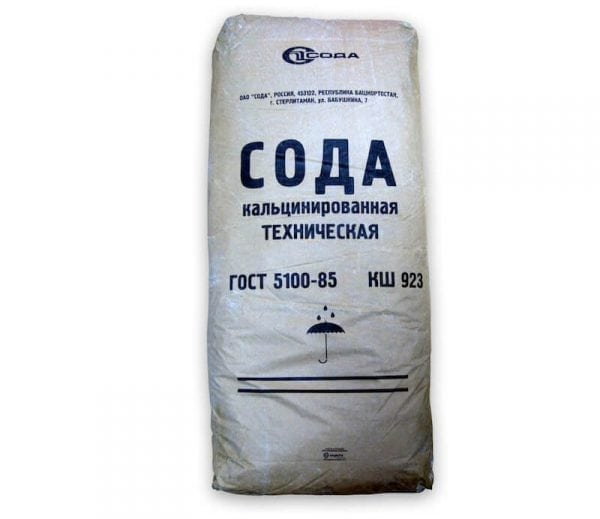

Next, we prepare a container for chromium plating and a solution with which we will process the necessary details. To prepare the solution, we take caustic soda, soda ash and silicate glue in equal amounts. We dilute all materials in water and stir.Next, bring the composition to a boil and place the details in it. The task of the solution is to ensure the removal of grease from plastic parts.

Immediately before starting chrome plating with your own hands, you need to put on protective clothing. After that, you can begin the main work.

to contents ↑The process of chrome plating

First of all, you need to connect the workpiece with a wire to the transformer. Then we take a brush, also attached to the transformer, and fill it with electrolyte. We apply an electrolyte layer to the surface. You need to do this gently and smoothly - with movements up and down. The electrolyte layer must be sufficient so that the applied coating is preserved for the maximum possible period of time. During operation, we monitor the presence of electrolyte in the brush and, if necessary, add the composition again.

Note! It is recommended that you do at least thirty brush passes on each surface spot.

At the end of electrolyte deposition, the surfaces are washed under running water. Then let the parts dry. We rub already dry surfaces with a piece of cloth to a state of gloss.

Useful Tips

- In some cases, it is not possible to do chrome plating with your own hands, and then you can choose an alternative way to give the part an effective look - nickel plating.

- Chrome plating allows you to reflect the light of the Sun, but over time this property of the treated surface is lost. Therefore, you should regularly look after the chrome surface. Care consists in periodically washing parts in warm water using household chemicals. After washing, clean the parts with a lint-free cloth. Coarse fabrics or brushes can harm the chrome surface.

- Low temperatures negatively affect the appearance of the treated surfaces - they fade.

- After finishing chrome work, it is necessary to polish the surface.

Chrome plating parts made of plastic - although a feasible task, but rather laborious. You will also need a significant amount of devices, some of which (for example, a transformer) cost a lot of money. Therefore, in the absence of the need for regular chrome plating or a small amount of work, it is easier to turn to specialists for help.