To improve the decorative properties, metal parts can be chrome plated. The technology is widely used in the automotive industry and a number of other sectors of the economy. Chrome plating of parts is also required to protect products from damage, improve their physical qualities. This metal processing method has a number of other advantages and advantages.

- The need for chrome plating

- Scope of chromium plating

- Chrome plating technology

- Galvanic method of chromium plating

- Electrolytic chromium plating method

- Chromium Diffusion Method

- Chemical chromium plating

- Catalytic Chrome Plating Method

- Vacuum chrome plating

- Thermochemical chromium plating

- DIY chrome plating

- Workplace preparation

- Room chrome tools

- Source of power

- The composition and method of preparation of electrolytes

- Surface preparation

- Chrome plating

- Possible defects and their causes

The need for chrome plating

Metal chrome is understood to mean the process of metallization with chromium to improve the surface properties and characteristics of elements. During chromium plating, diffuse saturation with chromium of various steel surfaces occurs. Chrome treatment is acceptable for ABC plastic, aluminum, brass, silumin.

Chrome coating gives the appearance of the parts a more beautiful appearance, ennobles them. The chrome layer provides the original metallic color, alloy wheels of the car, headlight reflectors, motorcycle parts, souvenirs or home furnishings begin to look more aesthetically pleasing.

Other advantages of chrome plating:

- Protection. Applying a layer of chromium helps to increase the resistance of products to temperature extremes, increases corrosion and erosion resistance, and reduces susceptibility to mechanical damage. Parts become superhard (950 - 1100 units on an appropriate scale), therefore they respond less to chemical damage and do not oxidize.

- Recovery. The service life of the base is seriously increased, large and small parts become very resistant to wear. With a low depth of wear, chromium plating completely restores the product (for example, cracks up to 1 mm deep are closed at the shafts and bushings).

- Reflective qualities. Some elements of the car are chrome plated to increase visibility in the dark. Reflection improves the decorative qualities of technology.

- Purity. Chrome plating products will protect them from dirt and dust, as it prevents the adhesion of various contaminants.

Compared to nickel plating, chromium plating has fewer disadvantages: the cost of services is lower, the coating will be harder and more durable. The use of nickel wins only in decorative qualities, as the surface becomes even more aesthetically pleasing.

to contents ↑Scope of chromium plating

It is difficult to completely describe all areas and areas where technology is used. Chrome plating is indispensable in the furniture industry, hardware, finishing elements are treated with chrome. The technique is popular in the manufacture of plumbing - the element is applied to the external and internal surfaces of pipes, bathtubs, sinks, and is used to cover pens, faucets.

In the automotive industry, technology is used to manufacture:

- overlays and reflectors;

- aluminum discs;

- body elements;

- pistons;

- compression rings;

- rollers and axles.

Chrome plating is used in the production of rubber, plastic (chrome is applied to calender shafts and molds), and various measuring tools. The material is covered by those elements that rub against each other so as to increase their wear resistance.

to contents ↑Chrome plating technology

There are different ways of chrome plating, some can be used at home, having the appropriate equipment.

Galvanic method of chromium plating

Galvanic chrome plating of parts is the most popular method, because all actions can be done with your own hands. Electroplating involves placing parts in a special solution with a specific composition, from where, under the influence of waves (solitons) of electric current, chromium atoms will be deposited on the surface. Having the right set of devices for chromium plating, you can independently create a high-quality coating by galvanization.

to contents ↑Electrolytic chromium plating method

One of the varieties of electroplating. When using electrolysis, tri- or hexavalent chromium gives the product the desired “metallic” look. When using a trivalent element, the main substance of the solution is chromic anhydride. The use of hexavalent chromium differs from the previous method by the presence of chromium sulfate in the composition of the solution.

When carrying out electrolytic chrome plating of disks or other parts, it is important to strictly observe the proportions of the components. Otherwise, the protective layer will quickly peel off or there will be spots on it, uneven dullness and insufficient gloss.

to contents ↑Chromium Diffusion Method

Chromium is sprayed using a galvanic brush. At home, this method is preferable, because the master will not need to use the bath. It is especially recommended to perform the procedure for parts made of aluminum, carbon steel, alloys with silicon.

Chemical chromium plating

The use of chemicals helps to restore chromium from its salts. In the case of chemistry, no electric current is required. Usually, phosphorus compounds, sodium citrate, glacial acetic acid, sodium hydroxide 20% are taken as reagents.

Before applying the reagents, the parts are coated with a layer of copper. After the work is completed, the workpieces are washed in water, dried, polished (initially the items have a dull gray color).

to contents ↑Catalytic Chrome Plating Method

A subspecies of chemical chromium plating of ferrous or non-ferrous metals, involving the application of a liquid without acids in the composition. The technology is safe for humans and helps to create original, unusual effects.

Catalytic chromium plating can be applied to conventional and flexible products (the latter is not possible with electrolysis, the coating will peel off).

Usually, silver is used as a reagent in an alkaline solution of ammonia, and formalin or hydrazine as a reducing agent. The use of silver makes the item milky with a mirror surface.

to contents ↑Vacuum chrome plating

The technology belongs to chemical metallization and has another name - the PVD process. It gives the condensation of chromium vapor on the surface of the part after placing it in a special vacuum chamber. In this installation, at negative pressure, the chromium is heated to the evaporation temperature, then settles like fog on the product.

Calculation of pressure, the period of chromium plating will depend on the degree of wear of the part, the type of material. After vacuum chromium plating, the thickness of the metal layer is minimal; therefore, the part is coated with a special spray paint from the top or varnished.

to contents ↑Thermochemical chromium plating

Apply means in powders, consisting of chamotte, ferrochrome. The technique is similar to that for chemical chromium plating, only the product will undergo heating in the process.

DIY chrome plating

In order to repair products with a result no worse than according to GOST, it is important to strictly follow the sequence of work, prepare the necessary equipment.

Workplace preparation

To comply with safety measures, in order not to breathe harmful, toxic substances, it is necessary to make a detailed preparation of the room for chromium plating.

Follow these steps:

- Provide good ventilation. If work is carried out in the garage, open the doors, create forced ventilation in other rooms.

- Buy and apply personal protective equipment - glasses, a respirator, gloves made of rubber or latex, an apron, overalls.

- Prepare dense bags for the disposal of industrial waste, which can be very caustic, harmful.

- Remove any organic matter from the room, as it will deteriorate when it comes in contact with pairs of chromium compounds.

- Immediately before work, lubricate the nasal cavity with a mixture of petroleum jelly and lanolin 2: 1.

Room chrome tools

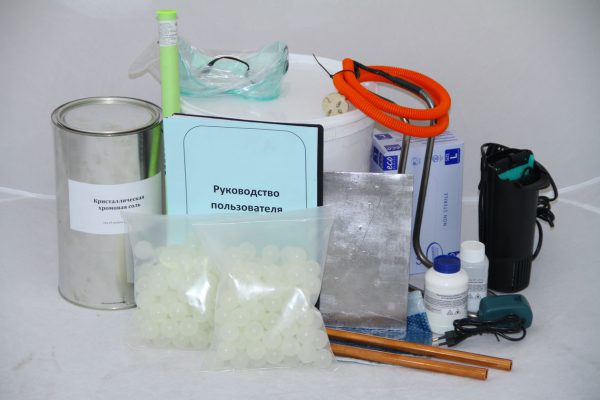

For galvanization, you need to prepare such tools and devices:

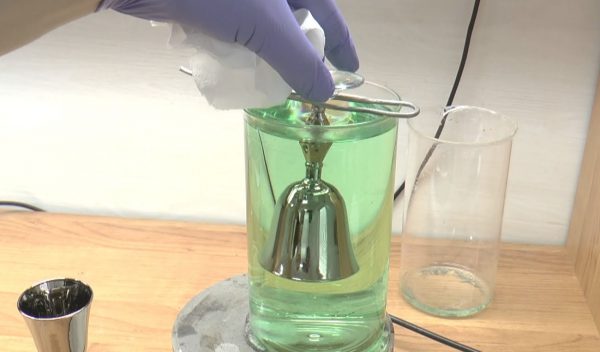

- The bath is galvanic. It can be any glass, propylene, polyethylene container, an enameled basin is suitable, for chrome plating of small objects - ordinary glass jars. The selected container should be placed in a wooden box, which is insulated from the inside with fiberglass and a layer of mineral wool. A tight fitting lid is needed for the tank.

- Device for heating the electrolyte. Ceramic heater (tubular electric heater), which will not be destroyed by contact with chemicals, is best suited for this purpose. Any other suitable heater may be used.

- Electrodes A lead plate, which is placed in a container, will serve as an anode during chromium plating; a clip holding a part will act as a cathode. When placed in a container, the part must not touch its edges.

- Thermometer with values up to +100 degrees Celsius.

to contents ↑Professionals use special equipment for chrome plating - bathtubs, electrical installations, washing and drying, ventilation systems. Even when using "home analogs" in the tank, the same chemical processes will occur, so the result will be close to industrial.

Source of power

To apply chromium, you need the right battery. A grounded DC source is suitable, the voltage of which is regulated within 1.5 - 12 V, the maximum current is 20 A. To adjust the power, the source must be equipped with a rheostat.

The composition and method of preparation of electrolytes

To precipitate chromium, you need to boil and cool the water or buy distilled. For each liter of water take 250 g of chromic anhydride, 2 - 2.5 g of sulfuric acid. The specific gravity of the latter should be 1.84 g / cu. cm.

A method of preparing an electrolyte for chromium plating is as follows:

- Fill the container with ½ water. The temperature of the liquid should be + 60 degrees.

- Carefully pour chromic anhydride, mix until dissolved.

- Pour in water until the bathtub is full.

- Add acid.

- Withstand the electrolyte for 3.5 hours under the influence of the rated current, which will help to equalize the density.

As a result, the color of the liquid should turn dark brown. After it settles for 24 hours in a cool room, then it is used for its intended purpose.

to contents ↑Surface preparation

The thoroughness of the preparatory measures will determine the life of the finished coating and its appearance. First, the part must be cleaned, washed, removed any contaminants. For better cleaning, you can use an emery cloth with fine grain or a grinding machine. It is important that the paint, varnish, rust are completely removed.

After cleaning, the part should be degreased. Take calcined water (50 g of calcined water is diluted in a liter of water), add 150 g of sodium hydroxide, 5 g of silicate glue. The amount of solution can be increased if necessary, while maintaining proportions. All components are heated to +90 degrees, they are kept in the product for 20 minutes. The time can be increased up to 1 hour if the product is very dirty.

to contents ↑Chrome plating

The chromium plating process is simple, proceeds according to the following steps:

- Heat the finished, settled electrolyte to +52 degrees, then keep this temperature constantly.

- In a container where an anode and cathode are already installed, put the part, heat it up to the specified temperature.

- Apply voltage, hold the product for 20-60 minutes depending on the shape, type of bends.

- Remove the product, rinse with distilled water.

- Dry the part for at least 3 hours, completely eliminating contamination, touching by hands.

Chrome plating carried out with even greater caution. The vapors released are very toxic, therefore it is forbidden to metallize plastic in a residential area.

In the process, a galvanic brush with a bristle of 25 mm diameter is used, which is wrapped with lead wire. The brush is attached to the end of the vessel in which the electrolyte is poured. A diode is fixed from the second end, a step-down transformer is used in the circuit. Plus, the transformer is directed to the anode of the diode, the bristle winding is connected to the cathode. Evenly apply the solution to the part, passing through each zone about 20 times. Then the product is dried for 3 hours.

to contents ↑Possible defects and their causes

Often during metallization, an effect such as hydrogenation occurs - an increase in the hydrogen content in chrome steel. Due to a similar problem, the strength and ductility of the metal are reduced due to a change in its crystal lattice. The reasons for hydrogenation have become diverse, most often this is due to an increase in temperature during galvanization.

Other troubles that may happen when chrome plating products:

- Gloss unevenness. It happens at high current, which is supplied to the anode. Completely shine may be absent with a small or too large amount of chromic anhydride, exceeding the volume of sulfuric acid.

- Brown spots. If there are such defects on the part, the anhydride norm in the solution is greatly overestimated or there is not enough sulfuric acid.

- The softness of the coating. The reason is the low current strength during galvanization or a decrease in water temperature.

- Quick chrome detachment. The reason is poor degreasing before work, a decrease in the temperature of the solution.

- Craters on the surface of the product. It happens due to the retention of hydrogen bubbles on oxidized, porous substrates.

An excellent result can only be obtained with strict adherence to technology. This will give the desired effect, saving a significant amount of money.