Corrosion on metal products is a natural phenomenon. It occurs on steel and other metals in places of violation of the integrity of the protective coating in contact with water, oxygen or aggressive media. An important role in the appearance of rust is played by temperature differences, various atmospheric factors. A rust converter has been developed to remove defects that have already appeared - for a car, such a tool will be indispensable, because it extends the life of many parts.

- What is a rust converter for?

- The principle of operation of the converters and their composition

- Varieties of rust modifiers

- Acid Converters

- Neutral Converters

- Rust to soil converter

- Rust Converters with Zinc

- How to choose a good rust converter

- Rating of the best rust converters

- ASTROhim

- Polyform Red

- Hi gear

- Runway

- Autoprofi

- Fenom

- Permatex

- Tsinkar

- "Chemist"

- Using Converter

- How to make a do-it-yourself converter

What is a rust converter for?

If you do not properly care for metal products, rust will appear on them sooner or later. Even stainless steel, cast iron, non-ferrous metals and alloys are subject to corrosion. Despite the presence of a strong oxide film under adverse conditions, there is a risk of its damage and the appearance of small or deep defects. Operating the product in humid conditions or constant contact with chemicals, reagents and salts accelerates the corrosion of metals.

If a problem is detected at an early stage, a rust converter helps to cope with it. This tool will also remove a thicker layer of red-brown plaque: the main thing is that the metal does not rot through, and then its functions and appearance can be restored. A chemical solution not only converts metal oxides into a safe, loose mass that is easy to remove mechanically, but also serves as a preventative measure for corrosion in the future.

to contents ↑The principle of operation of the converters and their composition

On sale there are various tools related to the group of rust converters. All of them, despite the unequal components in the composition, work according to a similar principle - they transform iron oxide into chemically inert substances. Most often, the composition of the converters is represented by phosphoric acid - the antipode of rust, or other acids. Such chemical elements actively react with a layer of corrosion and convert it to salts, which can be easily removed from the surface of a metal product. The acid minus has one drawback: if after work they are not washed off the surface, they themselves can become a source of the corrosion process.

To get rid of rust on the metal and prevent its development in the future, more advanced compounds have been developed. They may include:

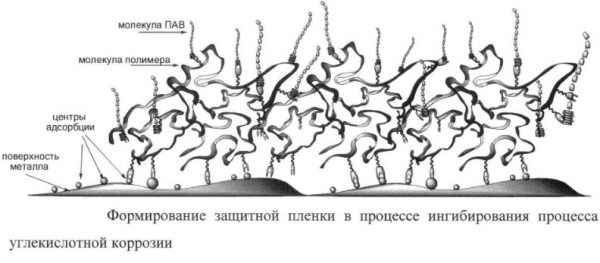

- Corrosion inhibitors. They protect metal substrates from water, temperature changes, aggressive chemicals for a long time. Most often, zinc acts as a corrosion inhibitor. This chemical element binds to oxygen atoms, as a result of which a strong film is formed, which reliably protects carbon steel, stainless steel from destruction.In addition to zinc, manganese or tannin can act as a corrosion inhibitor.

- Thickeners. These synthetic substances are incorporated into rust converters to facilitate application and retention on the surface. Without thickeners, the product will drain from a vertical or inclined base, and the effect will not be fully manifested.

The composition of the converters may include additional substances - film formers, flavors, various additives that enhance the effect of the action of the main elements.

to contents ↑Varieties of rust modifiers

In shape, all converters can be divided into aerosol, gel, pasty and liquid. The means in the cans are ideal for hard-to-reach places, if the bottle has a special flexible nozzle. To process large areas, it is economically feasible to purchase thick or liquid compositions in banks, applied with a brush or spray.

to contents ↑Gel transducers in tubes are excellent for removing small (point) elements of rust and just emerging corrosion. The composition and principle of operation of the funds can be classified into several groups.

Acid Converters

This is the largest group of tools to remove corrosion on metal products. Most of them are made on the basis of phosphoric acid - an inorganic substance of medium strength or include other tannic acids and their combinations. After contact with rust, iron oxide is converted to iron phosphate - an inert substance that does not harm the metal and is easily removed from it.

Acids against rust have many advantages:

- can be used at any stage of the corrosion process;

- suitable for thick and thin metal, suitable for car body, household appliances, various metal structures;

- not prohibited for winter use, work equally effectively at any temperature.

Neutral Converters

Such products do not include acids. The role of the converter in them is performed by tannins - phenolic compounds of plant origin with tannic properties. They interact with rust, transforming iron oxides into corrosive inactive substances. Tannins improve the adhesion of metal with topcoats - varnishes, primers, paints.

The composition of neutral converters is enhanced by the action of special additives, which increase the penetration depth of the solution to 150 microns or more. Such products can be used against corrosion on ferrous and non-ferrous metals, alloys, and delicate surfaces; they are ideally suited for treating the body and internal components of a car, preparing iron for concreting, and applying mastics. Their advantages are as follows:

- lack of acids in the composition; therefore, it is not necessary to rinse the product before operation;

- enhanced action due to added additives;

- deep penetration, rapid penetration of even a thick layer of rust;

- the possibility of using as a primer for metal;

- application by any method, including using high-pressure apparatuses;

- lack of mercury, heavy metals, harmful impurities in the composition;

- fire and explosion safety.

Rust to soil converter

Such funds are also called soil. They contain tannic acid in the composition, but additionally include various organic polymers (for example, ethylene glycol monobutyl ether, butoxyethanol). The latest generation of rust modifiers convert metal oxide to a primer. Best of all, they have proven themselves when working with multilayer rust, because they have a powerful effect.

to contents ↑After washing off the loose mass, a protective layer is formed on the surface of iron or another metal, which prevents the penetration of moisture, steam, and chemicals. The base becomes more durable, resistant to damage, which seriously increases its life.

Rust Converters with Zinc

The main component in such products is zinc oxide, which settles on the surface of the metal, eliminates corrosion and prevents them in the future. Before use, it is important to properly process the product with sandpaper, otherwise the effectiveness of the funds will be reduced. Such converters are especially popular when working with a car body - the bottom, wheel arches, other elements susceptible to corrosion.

to contents ↑How to choose a good rust converter

In the fight against corrosion, do not postpone the processing of products for a long time, otherwise the focus will increase significantly. Choosing a converter that easily removes small elements is much easier than one that can dissolve a thick layer of rust. Before buying, it is important to assess the type of surface: for horizontal substrates, cheaper compositions with a liquid texture are suitable, for inclined and vertical ones, it is worth buying pasty or gel products.

If rust has already formed on the metal, the best converter for it will have an acidic or neutral composition. Zinc fluids are ideal for preventing rust, especially when it comes to car parts. For hard-to-reach spots, it is recommended to choose aerosolized formulations with a long nozzle, or use spray guns with special tips.

In general, a high-quality rust converter will be characterized by the following properties:

- defect removal efficiency;

- deep penetration;

- security for the basics;

- lack of toxicity;

- speed of action;

- economical consumption;

- ease of application;

- sufficient duration of action.

Rating of the best rust converters

According to reviews of professionals and motorists, there is a certain list of rust converters that have the highest quality and are in demand on the market.

ASTROhim

This tool has a complex composition - includes phosphoric acid, corrosion inhibitors and zinc ions. After application to the rust layer, the latter is quickly transformed into salt, which can be removed from the surface mechanically. Residues of phosphates become the basis for the formation of a durable film that protects the metal. The use of Astrochem contributes to better staining or priming, as it enhances the adhesion of the treated product to coatings.

to contents ↑You can use the composition at temperatures + 10 ... + 30 degrees. It is applied in 2-3 layers, spraying in a small amount. Astrochem has a low price, penetrates into inaccessible zones, and is sold in containers of different volumes. After use, it must be washed off, otherwise there is a risk of damage to the metal in the future.

Polyform Red

The composition of the converter includes organic and inorganic acids, corrosion inhibitors, emulsifiers, detergents. The tool is considered very effective in creating a passivated layer on the metal, and also removes existing rust. It eliminates the bases of hydroxides, oxides that form on the surface of iron, cast iron, aluminum, chromium, nickel, and helps restore the luster of metal products. Polyform, among other things, eliminates old burnishing, scale, chalky deposits, wedges rusted compounds.

to contents ↑Hi gear

A rust converter of this brand called NO-RUST is sold in the form of aerosols of 255 and 368 ml and is considered a means of deep penetration. It transforms rust into soil, has a combined acid composition. Due to the ejection of a powerful jet from the cylinder, even hidden cavities and hard-to-reach areas of the product can be processed.After removal of corrosion, a protective film of a dark gray color is formed on the surface, which is subject to coloring, applying varnish and is not affected by solvents, water.

to contents ↑Runway

This tool is highly effective, but quite expensive and "capricious" in use. It is not applied at low temperatures, it does not tolerate temperature extremes, and the created film requires grinding, otherwise the finish coatings do not fit well on it. However, Runway offers a high degree of protection and is well suited for most metals and alloys.

Autoprofi

This composition belongs to the professional category, it is based on phosphoric acid and is designed to stop corrosion and create a strong iron-phosphate coating. The tool is suitable for ferrous metals and is most often used for car bodies, grilles, fences, various metal structures. It is realized in a bottle with a manual trigger type spray gun.

Fenom

The Fenom Rust-to-Primer Converters provide effective protection and are ideal for subsequent staining. As a result of applying the composition to the surface, an iron-manganese film is formed, which increases the adhesion of the metal to bitumen mastic or coatings 3 times. The solution does not interfere with the welding, does not impair the quality of the welds, and remains in the form of a film on the surface for 5–7 years. After application, it does not require rinsing, and this is its great advantage.

to contents ↑Permatex

It is considered one of the highest quality rust-to-soil converters. It is available in the form of a gel, which is applied with a spatula and quickly changes the rust layer to the finished soil film, which can be painted with any paintwork. It is convenient to work with the gel, it does not run off surfaces, starts acting immediately and can even be applied to rusty metal. If the corrosion layer is large, it is recommended to perform 2 application of the agent at intervals of 30 minutes.

The features of this rust converter are as follows:

- suitable for processing pipes, valves, fences, containers, equipment, trailers, car parts;

- does not require rinsing after the end of the action;

- works as a rust remover and as a primer;

- can be applied to wet metal;

- used at + 10 ... + 32 degrees;

- does not flow, does not bubble on any surfaces.

The tool is not recommended for processing the external part of the body - it can damage the paintwork. The composition has a rather high price, although its consumption is low.

to contents ↑Tsinkar

This converter is one of the most popular in the processing of domestic cars. It contains active acids, zinc and manganese, which help protect the base from corrosion for a long time by mechanical and electrochemical methods. After applying the composition, a reaction occurs, as a result of which the rust is converted into a strong protective film.

to contents ↑Tsinkar sold in bottles - ordinary and with a spray, and the second option is more convenient to use. The product is evenly distributed over the surface, is not fire hazardous, does not require rinsing. When buying, you need to carefully inspect the bottle, otherwise there is a risk of running into a fake: the original is sold in orange or red containers.

"Chemist"

Zinc-based Chemist rust converter has a liquid texture; it is used to remove corrosion and prepare the car body for painting. After deposition on the metal, a gray-white zinc coating appears, while a strong primer layer is formed.

Advantages of the product:

- easy and quick application;

- optimal vial volume (500 ml);

- does not require rinsing;

- effectively protects against corrosion;

- prevents metal decay.

to contents ↑It is necessary to work with this composition carefully, with observance of individual protection measures - it contains toxic components. "Chemist" is able to corrode some types of coatings, which must be taken into account when external processing of the body. Also, the tool can spoil the headlights in case of accidental contact, so their surface is better to reliably protect before work.

Using Converter

The correct procedure for using a particular solution can be clarified from the instructions, but most converters are applied using a similar technology. First you need to prepare the foundation:

- remove loose rust, which is easily removed mechanically, exfoliates without much effort;

- strip the metal with a brush or emery cloth;

- wash the surface, degrease.

Then you can proceed to the main stage. It should be applied with a brush, spray, irrigation (depending on its shape and density), wait for the set time. With a strong rusty coating it is recommended to repeat the application again after 10-15 minutes. After the total exposure time, you need to brush off the loose mass with a brush or rinse off - as indicated in the instructions. After washing, the surface must be thoroughly dried, and then primed and painted, if necessary.

To get a decent quality of the finished coating, it is important to follow these tips when working:

- first test any rust converter in an inconspicuous part of the part;

- apply a layer of such thickness as specified by the manufacturer (if necessary, use special instruments to measure the indicator);

- wait for the time to soften the rust, and only then proceed with the removal of plaque;

- gently wash off the resulting primer so as not to scratch the finished film.

How to make a do-it-yourself converter

Some craftsmen prepare rust remedies on their own. This is possible with certain supplies and equipment. The procedure will be as follows:

- take a rechargeable battery (12-30 V), zinc in any form, a self-tapping screw, soldering acid, wire, cotton wool and a rag;

- wrap a piece of zinc with cotton, then a rag, attach a self-tapping screw with a wire to it;

- moisten a rag with soldering acid, working in durable gloves;

- connect the wire to the battery;

- apply the zinc wrapped in a rag to the place of rust, wait 10 minutes;

- wash off the acid and formed plaque.

The rust converter is one of the most effective means in the fight against corrosion that has already appeared and is an excellent method for preventing its occurrence. You should choose a quality composition and apply it correctly, and the result will be no worse than when performing a job by a professional.