Processing with natural or artificial wax of any tree is used to protect the surface of the product from mold, rot, damage and insects. With the help of wax, a tree can not only protect against decay, but also highlight its texture.

- Technological process

- Woodworking with finished wax compounds

- Features of wood processing wax

- Gum production

- Waxing rules

Any wood needs protection from the effects of ultraviolet radiation and chemical damage. As protective compositions, impregnations based on paints and varnishes, as well as oil bases, are used. Wax is a reliable means of protecting wood from moisture.

Waxing is an old, effective way to coat wooden structures. Today, there are many similar formulations on sale. Finished components make up by adding:

- beeswax;

- inorganic additives;

- oils.

The solution can be used immediately after opening the can. After application, the board is transformed, becomes smooth with a velvety hue. Waxing reliably protects the wood from the ingress of harmful moisture, and this method is suitable for processing all types of wood. Today you can buy such a composition of any color.

to contents ↑Technological process

Wood as a building material has many positive qualities, and wax treated will last longer. If you plan to cover a material that already has any coating with this compound, you must first prepare the surface before waxing.

First of all, we remove all the old layers from the surface of the material. The varnish coating can be removed using a solvent, which is applied to the product several times until the natural board is completely exposed.

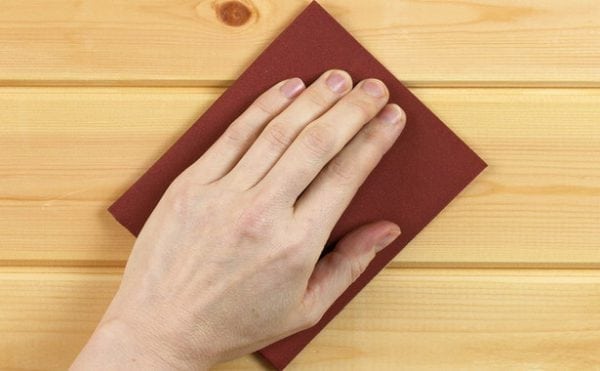

Residues are removed using warm water and abrasive products. All minor blotches of varnish that the solvent did not take are removed mechanically - with a knife or blade. The cleaned surface must be sanded for better adhesion before waxing. The surface must be thoroughly dried and sanded before sanding.

Smooth and smooth wood surface indicates that you did everything right. Waxing wood products and antique furniture is a great way to protect against damage. They can safely cover wooden unpainted surfaces, as well as apply several layers on top of the varnish layer.

to contents ↑Woodworking with finished wax compounds

Many varieties of wax formulations contain soft beeswax diluted with turpentine. Pastes are sold in cans and are a type of polishing materials. Usually they are applied with a special swab, but you can use a thick brush, as well as a steel washcloth for washing dishes. Wax paste is an excellent finishing component that can be applied to other coatings after oil impregnation.

Liquid wax is used when processing large surfaces, such as massive panels, which are applied with a brush. Compositions for floors have a transparent base in the form of mastic and are used in difficult operating conditions.

Painted waxes are mostly dark colors and are used for restoration work. Their purpose is to hide small scratches from the eyes. Usually, wax formulations are found in white or yellow - like oil, which does not leave a shade on the surface.

For the decoration of oak, brown shades of impregnation or black are used, created to enhance naturalness when the board shows its texture.

In order to restore the color of cedar or pine, apply golden impregnation, and to give freshness to the mahogany - choose red mastics. If you apply one composition to another, you can achieve a smooth transition of tones. Chairs and tables, items of frequent contact with clothes are not covered with dyes, oil, as well as wax - to avoid damage to clothing.

Before waxing a tree, it should be prepared. To do this, the unpainted surface is ground and degreased with a solvent. It will not be superfluous if the board is primed before waxing. But this is not necessary, since there is no need to fill the pores of the tree. In the case of applying a primer layer, it must be sanded with a fine sandpaper.

Wax paste is applied with a swab soaked in circular motions in several layers. Having processed the entire surface, it must be rubbed along the wood fibers. With difficulties in grinding, it is worth briefly heating the jar over low heat. The second layer is applied a few minutes after the first, but the mashing is already across the fibers.

After the solvent vapor evaporates, in time - about a day, several more layers of the substance should be applied to the surface and after complete drying, polish with a soft cloth. If you continuously rub the treated surface with a clean rag, you can even achieve mirror effect.

to contents ↑Features of wood processing wax

After applying wax on the surface of the tree, a slight yellowish tint is visible. This is waxing, impregnation with the ancient method of processing wooden products and parquet. The wood structure becomes unusually beautiful, the board acquires not only a shade of naturalness, but also exudes a wonderful smell of nature. This method is considered one of the most noble, because the tree becomes unusually smooth and soft under beeswax.

Some craftsmen painstakingly polished the waxed surface to a mirror finish. Gum waxes are found on sale, which are used in liquid form with the addition of solvents. The composition is based on beeswax and pine resin or orange oil. The advent of mechanical tools of irons made it possible to use solid pieces without dissolving them using chemistry.

When processing the floor, hard varieties contain a small amount of chemistry, so they are standardly safely heated before use. Today in the market of building components, you can find wax with the color of the earth. It is necessary to apply such a composition with caution, since there is a chance to get an uneven layer, which will be difficult to fix, and the color difference will be striking. In order to change the color of the coating, do not use earthen paint, but it is better to impregnate the wood with a pre-stain, but not with oil.

Remember that the waxed surface has a healing effect on the human body and creates a favorable atmosphere in the room.The secret is that the tree under the wax continues to breathe, and electrostatic discharges do not form.

to contents ↑Gum production

Gum can be quickly prepared for application to the surface of wood. To do this, fill the metal tank with beeswax and melt it in a water bath. They put 30 percent of the wax on the base, add 20 percent of oil varnish and 50 percent of terpentine oil from the orange. After mixing the components, the impregnation with the molten substance, the beeswax is cooled until solidified. The product is used for rubbing wooden surfaces, parquet, etc.

Waxing rules

The more dissolved wax is in the composition, the richer the final protective solution becomes, so this process can be controlled at your own discretion. Liquid treatment is carried out during repeated processing of the wood structure, this procedure is recommended to be repeated several times in a row.

As a rule, the solution is already applied to the waxed surface. Wax compositions for floors have a hard substance, and can include several varieties of wax: based on bee, carnauba and ordinary. There are special waxes created on petroleum components, which contain chemical solvents without an oil base.

It is worth noting that the use of wax protective agents will significantly extend the life of wooden coatings and furniture.