Propylene and PVC pipes are widely used in the installation of heating, water, sewage systems. There are several ways to connect such pipes; one of the most popular is gluing, or “cold welding”.

- Plastic pipes for gluing

- Choosing glue for pipes

- Popular brands

- Glue Instructions

- Adhesive for polypropylene pipes

- Bonding procedure for metal-plastic pipe

- Work with a cast-iron radiator when leaking

To ensure the reliability of the seam was high, you must correctly choose the glue for PVC pipes. The strength of such a joint will be no worse than that performed by conventional welding.

to contents ↑Plastic pipes for gluing

Unlike metal pipes, polypropylene products can be mounted independently even without special skills. Experts prefer not to use ordinary plastic for pipes with hot water or heating pipes, but to use it for sewer communications. But some types of products (in alloys with metal) are quite suitable for both cold and hot water. Advantages of polypropylene pipes are undeniable:

- resistance to changing environmental conditions (lower pressure, lower temperature, higher humidity);

- lack of corrosion;

- long service life (more than 50 years);

- ease of installation, gluing, repair;

- moderate cost;

- safety for health.

Such a pipeline also has disadvantages. The elasticity of the material during heating can decrease, the expansion coefficient is high. Under the influence of the sun, some types of plastic age faster, which must be taken into account during installation.

Equipment at home with plumbing and sewage systems using PVC pipes can be performed by products of various types. Depending on the components and manufacturing technology included, these types of plastic pipes are produced:

- From polyvinyl chloride (PVC). The most rigid, gluing them is quite simple. They do not burn, do not respond to UV radiation, lungs. Unfortunately, chlorine is used in the production process, so PVC pipes are not environmentally friendly.

- Polyethylene. Very durable, flexible, easily tolerate even freezing water, do not burst. The inside is smooth, the water does not leave any deposits in them, deposits of impurities. Among the minuses, it is necessary to indicate that they are not suitable for hot water - they begin to melt. Connect with fittings with clamp. A separate variety is cross-linked polyethylene tubes, which are used for the underfloor heating system.

- Polybutylene. Suitable for water with temperatures up to +90 degrees, but are not mounted by gluing. Used in the installation of heating systems.

- Polypropylene Are applied to hot, cold water, for the sewerage, heating, are very simple in installation. They are connected by soldering, and they can also be welded.

- From metal plastic. They include aluminum, an aluminum alloy with plastic. Due to the three-layer base, they are suitable for water supply, heating, withstand temperatures up to +110 degrees.

Choosing glue for pipes

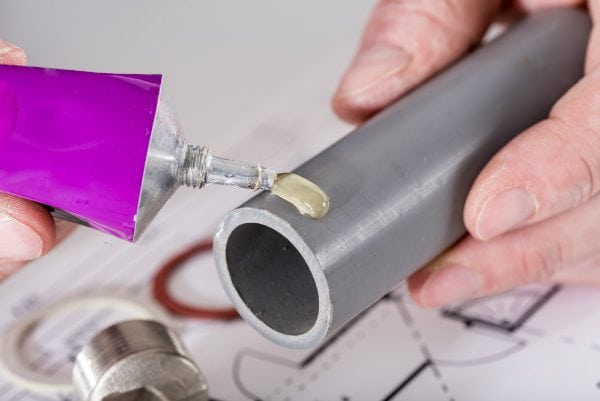

Special adhesives for sewerage and water supply systems are called cold welding. Such tools are able to distribute the load on the joint, which increases the strength and makes the service life of the pipes higher. Glue creates a reaction of polymer splitting in solvents in PVC and other plastic materials.After softening the wall, the fitting joins, in which the base is also softened. This process is also called chemical welding. Seam sealing will be 100% reliable.

All adhesive compositions can be divided into 2 groups:

- Adhesives for sewage hot fusion. They can also glue PVC water pipes, air ducts.

- Glues of cold drawing. Used for cold water pipes.

Manufacturers also divide adhesives into those intended for soft materials (corrugated pipe), and for hard products. Another classification is as follows:

- means capable of filling up gaps up to 0.8 mm between the pipe and the adapter;

- materials that do not close the gaps (the distance between the fitting and the pipe should not exceed more than 0.1 mm).

Typically, large gaps are formed at the junction in the sewerage system and the external water supply, where large diameter pipes are involved and sockets are used. Small gaps are characteristic of an internal water supply and heating system.

The choice of means by which it will be possible to seal products depends on a number of factors:

- place of installation of pipes - working conditions vary in pollution, liquid temperature, humidity and ambient temperature;

- water pressure - different compositions withstand unequal pressure;

- features of the load - if the pipeline has the ability to move due to a change in elasticity, you need a special glue;

- degree of harm to the body - a number of compounds are not suitable for use inside a person’s housing.

to contents ↑Means for making a weld may have different pour times. Usually it is 1–4 minutes. For hot welding, the curing time is higher - 30-60 minutes. The final polymerization of materials can last up to a day.

Popular brands

Cold welding tools include tetrahydrofuran in which a certain amount of polyvinyl chloride is dissolved. The following adhesives are used for HDPE (low pressure polypropylene) and PVC:

- Tangit PVC-U (Tangit PVS-U). It is the most popular means by which PVC-pipe can be glued, made in Germany. Comes with a brush with a convenient tip. The tool is allowed to be used for fastening drinking water supply systems. It is also suitable for connecting pressure pipelines.

- MARS. It is based on synthetic resins (epoxy) and organic solvents. The joint strength will be at a height, the stickiness of substances is very high.

- Koratac HF 300. Provides high-quality joining of pipes made of solid PVC, the seam is not destroyed by the action of water, steam, gasoline, alcohols.

- Era. Chinese product, characterized by great reliability, low price. It is delivered in cans of 0.1–1 kg; it is completed with a brush.

- Poxipol. It is a universal glue, suitable for any type of plastic pipe. The seam will withstand temperatures up to +110 degrees.

Less common brands of glue are Phoenix, Vinylite. They are no less reliable, but less common in stores.

to contents ↑Glue Instructions

Before brewing pipes with adhesive, it is important to carry out preparatory work. The pipeline construction must be carefully measured, after which the products must be cut. Sections of the required size should be made according to the markup made in advance using a pipe cutter. The slices should be perfectly even, otherwise the quality of the joint will be poor. Burrs from the ends are completely removed with the help of sandpaper, a file. Then do the following:

- pre-dock by inserting adapters (fittings) into the pipes, put a mark on which area to apply glue to;

- degrease the hole, the inside of the fitting with alcohol.

For work, you should also prepare a brush from natural bristles, if it was not included. The temperature in the room should be within + 5 ... + 35 degrees. After you need to proceed to gluing:

- mix glue thoroughly;

- apply the product in a thin layer on the pipe and sockets of the connecting fittings with movements in the longitudinal direction;

- insert the pipe into the fitting hole, focusing on the notes made (it is strictly forbidden to rotate parts);

- strongly compress the parts, hold for 15-30 seconds, as indicated in the instructions for a specific tool;

- remove excess glue with a napkin;

- Do not move the pipes from the place of work for 15 minutes, water can be supplied to them in a day.

All adhesives for PVC products quickly ignite, you must work with them carefully. To prevent harm should wear gloves, a respirator. To form the corners buy special corner fittings. For a more reliable joint, some masters prefer to cover the seam with sealant.

Defects during operation can occur for the following reasons:

- Non-glued spots. This happens due to uneven application of the composition.

- Full non-glue. The composition has dried prematurely, the docking of parts was carried out too late.

- Soft seam. This occurs at low temperatures in the room or at the early start of operation of the product.

- The porosity of the seam. This defect is typical for moments when air bubbles got into the glue due to poor mixing.

Adhesive for polypropylene pipes

The gluing technology of this type of material is practically no different from the connection of PVC pipes. Polypropylene adhesives may be similar. Often masters use tangit. Under this brand, a number of one-component products are sold that simply need to be applied to the surface of the pipe. Two-component products are also sold that must be mixed before use. They are more reliable, create the most durable seam, but will require more effort to work. Here is a list of other good adhesives for polypropylene products:

- Cosmoplast 500. One-component transparent adhesive, used in everyday life and industry. The adhesion to the surface is ideal, so the elements can be positioned even at an angle (glue is shown for corners and pipe joints). Of the minuses, it is necessary to name a very fast initial setting - 3-5 seconds. Complete polymerization occurs in 16 hours.

- Dow Corning 7091. It is a glue-sealant, the connection created by it will be resistant to water, temperature extremes.

- WEICON Easy-Mix PE-PP. A two-component composition for all types of plastic pipes, the basis of the product is methyl acryl. It freezes in a day, the initial setting occurs in 30 seconds.

The gluing algorithm for polypropylene pipes is similar to that for PVC products. First, the pipes are cut, then a test connection is made, after which gluing is carried out. After an hour, you can check the joint for leaks - this will immediately find the hole, close it in time and avoid pipe leakage in the future.

to contents ↑Bonding procedure for metal-plastic pipe

Sometimes in the water supply system or drain pipes made of metal-plastic, leakage occurs. I must say that such cases are quite rare, because the strength of the material is very high. Why can holes form? The aluminum pipe, which is the base, can leak only with installation errors or with serious mechanical impact on the product. Usually the reason is the non-compliance with the bending radius during installation, then a hole is formed at the bend. An incorrectly mounted fitting may also cause a problem.

When repairing, first you need to shut off the water and apply a temporary measure - apply a special adhesive tape or make a so-called bandage for pipes from a piece of rubber. How to seal a metal-plastic pipe? If the hole is small, you can seal it with epoxy or sealant. First you need to process the surface with sandpaper and degrease. Sandpaper will create the desired roughness, which will enhance adhesion. Apply a layer of glue, then wrap the joint with a bandage in 3-4 layers, lubricate with a layer of glue. After 12 hours, the pipe can be operated.

If a leak occurs due to damage to the fitting, turn off the water, disassemble the leaking end (remove the nut, pull out the pipe). It is important to inspect the o-ring, fitting, thread for damage and replace parts. If the pipe burst, you will have to completely replace it.

to contents ↑Work with a cast-iron radiator when leaking

It happens that the heating battery has flowed - the threaded joint has deteriorated, a leak has appeared on the section. For repair will be required epoxy adhesive and a bandage.The material is impregnated with glue, applied to the area of the hole. After setting, you can paint this area in the main color. This measure is considered temporary, and after turning off the heating, it is better to replace the radiator.

Battery cold welding is also used. A special tool is kneaded in the hands, applied to the site of damage. It quickly melts, seizes and allows the patch to exist until the heating is turned off.

Do not try to glue the radiators in case of a strong leak, which led to an emergency. It is better to immediately call a team of specialists who will stop the leak and change the radiator to a new one.